Mastering CLSI M07 Broth Microdilution: A Complete Guide for Antimicrobial Susceptibility Testing in 2024

This comprehensive guide details the CLSI M07 broth microdilution standard method for determining Minimum Inhibitory Concentrations (MICs) of antimicrobial agents against bacteria.

Mastering CLSI M07 Broth Microdilution: A Complete Guide for Antimicrobial Susceptibility Testing in 2024

Abstract

This comprehensive guide details the CLSI M07 broth microdilution standard method for determining Minimum Inhibitory Concentrations (MICs) of antimicrobial agents against bacteria. It provides researchers, scientists, and drug development professionals with foundational principles, a step-by-step methodological walkthrough, troubleshooting strategies for common pitfalls, and insights into method validation and comparison with other techniques like agar dilution (M07) and disk diffusion (M02). The article covers recent updates from the Clinical and Laboratory Standards Institute (CLSI), practical applications in drug discovery and clinical trials, and best practices for ensuring accurate, reproducible, and compliant results.

What is CLSI M07 Broth Microdilution? Core Principles and Standards Explained

Defining Broth Microdilution and the Role of CLSI Standard M07

Introduction

Within the rigorous framework of antimicrobial susceptibility testing (AST) research, broth microdilution (BMD) stands as the reference quantitative method for determining the minimum inhibitory concentration (MIC) of antimicrobial agents. This in-depth technical guide defines the BMD method and elaborates on the critical role of the Clinical and Laboratory Standards Institute (CLSI) standard M07, "Methods for Dilution Antimicrobial Susceptibility Tests for Bacteria That Grow Aerobically," in ensuring the accuracy, reproducibility, and clinical relevance of this foundational technique. This discussion is framed within the context of advancing thesis research on the M07 standard, focusing on its methodological specifics, interpretative criteria, and its position as the benchmark against which novel diagnostic technologies are validated.

1. Defining Broth Microdilution

Broth microdilution is a standardized laboratory technique where a bacterial inoculum of defined density is exposed to serial two-fold dilutions of an antimicrobial agent in a liquid growth medium, typically within a 96-well microtiter plate. After a defined incubation period (usually 16-20 hours at 35°C ± 2°C), the MIC is determined as the lowest concentration of the antimicrobial that completely inhibits visible growth of the organism.

2. The Role and Scope of CLSI Standard M07

CLSI document M07 provides the definitive procedural and quality control framework for performing BMD for aerobic bacteria. Its primary role is to standardize all variables to ensure results are reliable, comparable across laboratories, and clinically actionable. Key areas standardized by M07 include:

- Preparation of antimicrobial stock solutions: Specifies solvents, diluents, and storage conditions.

- Panel preparation: Details the formulation of cation-adjusted Mueller-Hinton Broth (CA-MHB) as the standard medium and the methodology for creating serial dilutions.

- Inoculum preparation: Mandates the use of the 0.5 McFarland standard and subsequent dilution to achieve a final bacterial density of ~5 x 10⁵ CFU/mL in each well.

- Incubation conditions: Defines time, temperature, and atmosphere.

- Reading and interpretation: Provides guidelines for determining endpoints and correlating MICs with clinical breakpoints (found in CLSI M100).

3. Detailed Experimental Protocol: Reference BMD per CLSI M07

The following protocol is a synthesis of the core methodology from CLSI M07-Ed13.

Materials:

- Cation-Adjusted Mueller Hinton Broth (CA-MHB)

- Sterile 96-well, U-bottom microtiter plates

- Antimicrobial agents of known potency

- Bacterial isolates, freshly subcultured

- 0.5 McFarland turbidity standard or densitometer

- Sterile saline or broth for inoculum preparation

- Multichannel pipettes and sterile reservoirs

- 35°C ± 2°C ambient air incubator

Procedure:

- Antimicrobial Stock Solution Preparation: Prepare a stock solution of the antimicrobial agent at a high concentration (e.g., 5120 µg/mL or 10x the highest concentration to be tested) using the appropriate solvent and diluent as specified in M07 Table 6A.

- Microdilution Panel Preparation: Using CA-MHB as the diluent, perform serial two-fold dilutions of the antimicrobial stock directly in the microtiter plate wells. Typically, a volume of 50 µL per well is used. One column of wells serves as a growth control (antimicrobial-free broth). Final well volumes before inoculation are 50 µL.

- Inoculum Standardization: Adjust the turbidity of a log-phase bacterial broth culture or saline suspension to match a 0.5 McFarland standard (~1-2 x 10⁸ CFU/mL).

- Inoculum Dilution: Dilute the standardized suspension 1:150 in sterile saline or broth to achieve a concentration of ~1 x 10⁶ CFU/mL.

- Plate Inoculation: Add 50 µL of the diluted inoculum to each well of the microtiter plate containing the 50 µL of antimicrobial dilutions. This step achieves the target final inoculum of ~5 x 10⁵ CFU/mL per well in a total volume of 100 µL.

- Incubation: Cover the plate and incubate at 35°C ± 2°C in ambient air for 16-20 hours.

- Endpoint Determination: Examine the plate visually or with an automated reader. The MIC is the lowest antimicrobial concentration that completely inhibits visible growth.

4. Key Quantitative Data from M07-Based Studies

Table 1: Acceptable Ranges for Quality Control (QC) Organisms in BMD (Excerpt)

| QC Organism | Antimicrobial Agent | Acceptable MIC Range (µg/mL) |

|---|---|---|

| Staphylococcus aureus ATCC 29213 | Oxacillin | 0.12 - 0.5 |

| Vancomycin | 0.5 - 2 | |

| Escherichia coli ATCC 25922 | Ciprofloxacin | 0.004 - 0.015 |

| Meropenem | 0.004 - 0.015 | |

| Pseudomonas aeruginosa ATCC 27853 | Tobramycin | 0.5 - 2 |

| Ceftazidime | 1 - 4 |

Table 2: Impact of Critical Variables on MIC Results

| Variable | CLSI M07 Specification | Consequence of Deviation |

|---|---|---|

| Cation Concentration | Ca²⁺: 20-25 mg/L; Mg²⁺: 10-12.5 mg/L in CA-MHB | Alters MICs of aminoglycosides (Mg²⁺) and daptomycin (Ca²⁺). |

| Inoculum Density | Final: 5 x 10⁵ CFU/mL (± 1 log) | Higher density can falsely elevate MIC; lower density can falsely lower MIC. |

| Incubation Time | 16-20 hours | Prolonged incubation can lead to trailing growth or degradation of labile drugs. |

| Incubation Atmosphere | Ambient Air (for non-fastidious aerobes) | Altered O₂/CO₂ can affect growth rate and MIC for some species. |

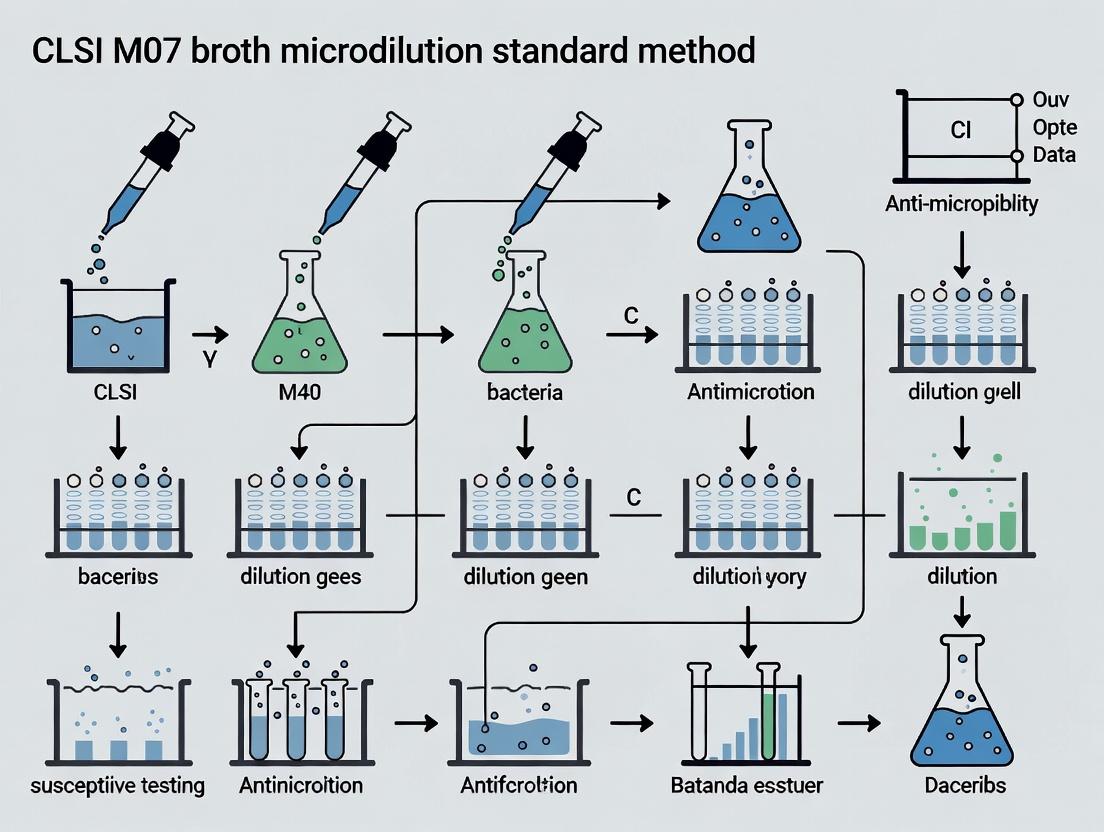

5. Experimental Workflow Diagram

Diagram 1: CLSI M07 Reference Broth Microdilution Workflow

6. The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for CLSI M07-Compliant BMD

| Item | Function | Critical Specification |

|---|---|---|

| Cation-Adjusted Mueller Hinton Broth (CA-MHB) | Standardized growth medium for non-fastidious aerobes. | Must contain defined levels of calcium (20-25 mg/L) and magnesium (10-12.5 mg/L) ions. |

| Microtiter Plates (96-well, U-bottom) | Reaction vessel for housing dilutions and inoculum. | Must be non-cytotoxic, sterile, and have low protein binding. |

| 0.5 McFarland Turbidity Standard | Primary standard for inoculum density preparation. | Can be commercial latex suspension or verified in-house barium sulfate standard. |

| CLSI QC Strains (e.g., ATCC 29213, 25922, 27853) | Quality control organisms to verify reagent performance and technique. | Must be obtained from a reputable source, stored properly, and subcultured per M07. |

| Antimicrobial Reference Powders | For preparation of primary stock solutions. | Must be of known and high potency (>90%), with purity verified. |

| Sterile Dimethyl Sulfoxide (DMSO) or Water | Solvents for initial dissolution of antimicrobial powders. | Choice dictated by M07 Table 6A; must be sterile and of reagent grade. |

Conclusion

The CLSI M07 standard is not merely a procedural manual; it is the cornerstone of robust, defensible research in antimicrobial susceptibility. For thesis research, a deep understanding of M07's tenets allows for the precise execution of the reference BMD method, enabling valid comparisons with novel AST platforms, investigations into resistance mechanisms, and studies on the pharmacokinetic/pharmacodynamic (PK/PD) correlates of efficacy. Adherence to M07 ensures that generated MIC data is of the highest quality, forming a reliable foundation for scientific discovery and clinical interpretation.

The Significance of MIC (Minimum Inhibitory Concentration) in Antimicrobial Testing

Within the framework of Clinical and Laboratory Standards Institute (CLSI) document M07 research, the Minimum Inhibitory Concentration (MIC) remains the foundational quantitative measure for assessing antimicrobial susceptibility. This in-depth technical guide explores the pivotal role of MIC determination via the standardized broth microdilution method, its interpretation in the context of pharmacokinetic/pharmacodynamic (PK/PD) indices, and its critical function in antimicrobial stewardship and drug development.

The MIC is defined as the lowest concentration of an antimicrobial agent that completely inhibits visible growth of a microorganism under standardized incubation conditions. In the research context of CLSI M07, broth microdilution is established as the reference method for MIC determination due to its reproducibility, scalability, and capacity for high-throughput testing essential for research and drug development.

Methodology: CLSI M07 Broth Microdilution Standard Protocol

Core Experimental Protocol

This detailed protocol is adapted from CLSI M07-A11 (2023) and subsequent updates.

Step 1: Preparation of Antimicrobial Stock Solutions

- Weigh the antimicrobial reference powder using an analytical balance.

- Dissolve in the appropriate solvent (specified by CLSI Appendix B).

- Filter sterilize (0.22 µm pore size).

- Aliquot and store at -70°C or below (unless stability data indicates otherwise).

Step 2: Preparation of Dilution Series

- Perform serial two-fold dilutions in cation-adjusted Mueller-Hinton broth (CAMHB) or other appropriate medium.

- Dilution range typically spans from 0.008 µg/mL to 128 µg/mL, encompassing expected clinical breakpoints.

Step 3: Inoculum Preparation

- Select 3-5 well-isolated colonies from an overnight agar plate.

- Suspend in sterile saline or broth to achieve a 0.5 McFarland standard (approx. 1-2 x 10^8 CFU/mL for Enterobacterales).

- Dilute the suspension in broth to achieve a final inoculum density of 5 x 10^5 CFU/mL in the test well.

Step 4: Microdilution Plate Setup

- Dispense 100 µL of each antimicrobial dilution into the wells of a sterile 96-well microtiter plate.

- Add 100 µL of the standardized inoculum to each test well.

- Include controls: Growth control (broth + inoculum), sterility control (broth only), and quality control (reference strain with known MIC).

Step 5: Incubation and Reading

- Incubate plates under atmospheric conditions (non-fastidious organisms) at 35°C ± 2°C for 16-20 hours.

- Read MIC visually or with automated readers. The MIC is the lowest concentration with no visible turbidity.

Key Quantitative Data and Clinical Breakpoints

The interpretation of raw MIC data relies on correlation with clinical breakpoints established by CLSI and EUCAST.

Table 1: Example MIC Interpretive Criteria (CLSI M100, 2024) for Pseudomonas aeruginosa vs. Ciprofloxacin

| MIC (µg/mL) | Interpretation (S/I/R) | Clinical Implication |

|---|---|---|

| ≤ 0.5 | Susceptible (S) | Standard dosing regimen likely effective |

| 1 | Intermediate (I) | May be effective at higher doses or at body sites where drug concentrates |

| ≥ 2 | Resistant (R) | High likelihood of clinical failure with standard dosing |

Table 2: Key PK/PD Indices Linked to MIC for Efficacy Prediction

| PK/PD Index | Target for Bactericidal Activity (Typical) | Description & Significance |

|---|---|---|

| %T > MIC (Time-dependent) | 40-70% of dosing interval (e.g., β-lactams) | Time the free drug concentration exceeds the MIC |

| AUC(_{0-24}) / MIC (Concentration-dependent) | 25-400 (e.g., Fluoroquinolones: ~125) | Area Under the Curve of free drug over 24h relative to MIC |

| C(_{max}) / MIC (Concentration-dependent) | 8-12 (e.g., Aminoglycosides) | Peak free drug concentration relative to MIC |

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for Broth Microdilution MIC Testing

| Item | Function & Critical Specifications |

|---|---|

| Cation-Adjusted Mueller Hinton Broth (CAMHB) | Standard medium ensuring reproducible cation concentrations (Ca2+, Mg2+) that affect aminoglycoside and tetracycline activity. |

| 96-Well Sterile Microtiter Plths | Polystyrene plates with low protein binding; U-bottom for easier visual reading, flat-bottom for spectrophotometric reading. |

| Reference Antimicrobial Powder | USP-grade powder of known potency, used for preparing in-house stock solutions for research. |

| Frozen or Lyophilized Panels | Pre-made panels with serial dilutions of multiple drugs, essential for high-throughput screening in development. |

| Quality Control Strains | E. coli ATCC 25922, P. aeruginosa ATCC 27853, S. aureus ATCC 29213. Used to validate test performance. |

| Densitometer or Spectrophotometer | For standardizing inoculum to precisely 0.5 McFarland (optical density ~0.08-0.13 at 625 nm). |

| Multichannel Pipettes & Reagent Reservoirs | For accurate and efficient dispensing of broth, inoculum, and antimicrobial solutions. |

Advanced Applications in Drug Development

MIC data feeds into critical development decisions:

- Determination of In Vitro Potency: Establishes baseline activity against target pathogens.

- Resistance Frequency Studies: Informs on the mutational prevention concentration (MPC).

- Combination Synergy Testing: Checkerboard MIC assays quantify fractional inhibitory concentration (FIC) indices.

Visualizing the Role of MIC in Research and Clinical Decision Pathways

Diagram Title: MIC Data Flow from Lab Experiment to Research and Clinical Application

Diagram Title: Integration of MIC with PK/PD to Predict Outcome

Within the rigorous framework of CLSI M07, the MIC is not a standalone number but the essential link between in vitro antimicrobial testing, research into resistance mechanisms, and clinical efficacy. Its accurate determination via standardized broth microdilution is fundamental for robust surveillance data, rational drug development, and the informed application of PK/PD principles to combat antimicrobial resistance.

The Clinical and Laboratory Standards Institute (CLSI) document M07 outlines standardized broth microdilution methods for the in vitro susceptibility testing of aerobic bacteria. As part of a broader thesis on refining and applying M07 methodology, this whitepaper details the critical foundational components: the formulation and preparation of broth media, the precise preparation of the bacterial inoculum, and the rigorous specifications of the microdilution plate format. Mastery of these three elements is fundamental to generating reproducible, accurate, and clinically relevant minimum inhibitory concentration (MIC) data.

Broth Media: The Growth Environment

Broth media must support consistent, rapid growth of non-fastidious aerobic bacteria without interfering with antimicrobial activity. Cation-adjusted Mueller-Hinton Broth (CAMHB) is the standard medium, with specific adjustments to ensure reproducibility.

Critical Components of CAMHB

The formulation is designed to control variables that significantly affect MIC results, particularly cation concentrations.

- Ca²⁺ Concentration: Adjusted to 20–25 mg/L (as Ca²⁺). Critical for testing aminoglycosides and tetracyclines, as excess Ca²⁺ can antagonize aminoglycoside activity.

- Mg²⁺ Concentration: Adjusted to 10–12.5 mg/L (as Mg²⁺). Excess Mg²⁺ can antagonize the activity of aminoglycosides against Pseudomonas aeruginosa.

- pH: Final pH must be 7.2–7.4 at room temperature. pH variations can drastically alter the activity of certain agents (e.g., macrolides, aminoglycosides).

- Thymidine/Thymine Content: Must be low to prevent antagonism of sulfonamides and trimethoprim.

Protocol for CAMHB Preparation:

- Rehydrate commercial Mueller-Hinton broth powder according to manufacturer's instructions.

- Adjust divalent cation levels by adding sterile solutions of CaCl₂ and MgCl₂ as needed. Confirm concentrations via atomic absorption spectroscopy or using commercial broth with verified levels.

- Adjust pH to 7.2–7.4 using 1N NaOH or 1N HCl.

- Filter sterilize (0.22 µm pore size) and store at 2–8°C.

Quantitative Specifications for Broth Media

Table 1: CLSI M07 Specifications for Cation-Adjusted Mueller-Hinton Broth

| Parameter | Target Specification | Rationale |

|---|---|---|

| Calcium (Ca²⁺) | 20 – 25 mg/L | Standardizes aminoglycoside & tetracycline activity |

| Magnesium (Mg²⁺) | 10 – 12.5 mg/L | Prevents false resistance in P. aeruginosa with aminoglycosides |

| pH | 7.2 – 7.4 (at 25°C) | Maintains optimal & reproducible drug activity |

| Thymidine Content | Low (<0.1 µg/mL) | Prevents antagonism of trimethoprim/sulfamethoxazole |

Inoculum Preparation: Standardizing the Challenge

Inoculum density is a primary source of variability in MIC testing. The M07 method standardizes this to approximately 5 x 10⁵ CFU/mL in each well of the final microdilution plate.

Protocol for Inoculum Preparation via Direct Colony Suspension Method:

- Select 3–5 well-isolated colonies of the target organism from an overnight (18–24 hour) non-selective agar plate.

- Transfer colonies to a tube containing 4–5 mL of sterile saline (0.85–0.9%) or Mueller-Hinton Broth.

- Vortex thoroughly to create a homogeneous suspension.

- Adjust the turbidity of the suspension to match a 0.5 McFarland standard using a densitometer or visual comparator.

- A 0.5 McFarland standard yields a suspension containing approximately 1–2 x 10⁸ CFU/mL for E. coli.

- Within 15 minutes of adjustment, dilute the standardized suspension 1:150 in sterile saline or broth to achieve a working inoculum of ~5 x 10⁵ CFU/mL.

- Example: Add 0.5 mL of the 0.5 McFarland suspension to 74.5 mL of CAMHB.

Protocol for Inoculum Preparation via Growth Method:

- Make a direct colony suspension as above, but adjust to a 0.5 McFarland standard using CAMHB.

- Incubate the suspension with shaking at 35 ± 2°C until it reaches the turbidity of a 0.5 McFarland standard (typically 2–6 hours).

- Dilute the actively growing culture as needed in CAMHB to achieve a working inoculum of ~5 x 10⁵ CFU/mL.

Verification: Inoculum density should be verified periodically by performing viable plate counts on the working suspension.

Plate Format and Testing Procedure

Microdilution plates are typically 96-well U-bottom plates, which facilitate the observation of small pellets of precipitated growth. Each well contains a serial two-fold dilution of an antimicrobial agent in a defined volume (typically 50–100 µL) of CAMHB.

Protocol for Plate Preparation and Inoculation:

- Plate Formatting: Antimicrobial stock solutions are serially diluted in CAMHB and dispensed into the plate. Columns 1-11 contain decreasing concentrations of drug. Column 12 is a growth control well (broth + inoculum, no drug).

- Inoculation: Add an equal volume (e.g., 50 µL) of the prepared working inoculum (~5 x 10⁵ CFU/mL) to each well of the plate, doubling the volume and halving the drug concentration. The final target inoculum is ~2.5–5 x 10⁵ CFU/mL per well.

- Sealing & Incubation: Seal the plate with a non-permeable lid or adhesive film. Incubate aerobically at 35 ± 2°C for 16–20 hours.

- Reading Results: Read the MIC as the lowest concentration of antimicrobial agent that completely inhibits visible growth of the organism. Use a reading mirror for accuracy. The growth control must show confluent turbidity, and the sterility control (broth only) must be clear.

Table 2: Standardized Parameters for M07 Microdilution Testing

| Parameter | Specification | Notes |

|---|---|---|

| Final Inoculum Density | 5 x 10⁵ CFU/mL (± 1 log) | Verified by plate count |

| Well Volume (Final) | 100 µL | 50 µL drug + 50 µL inoculum common |

| Antibiotic Dilution Series | Two-fold serial dilutions | Covers CLSI breakpoint range |

| Incubation Conditions | 35 ± 2°C, Ambient Air, 16–20 hrs | Extended times for certain drugs |

| Plate Type | 96-well, U-bottom | Facilitates pellet visualization |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for CLSI M07 Broth Microdilution

| Item | Function & Specification |

|---|---|

| Cation-Adjusted MH Broth (CAMHB) | Standard growth medium with controlled Ca²⁺ & Mg²⁺ levels. |

| Mueller-Hinton Agar (MHA) Plates | For subculturing and maintaining test isolates prior to testing. |

| 0.5 McFarland Standard | Turbidity standard for inoculum preparation (latex particle or BaSO₄). |

| Sterile Saline (0.85–0.9%) | For making initial bacterial suspensions and dilutions. |

| 96-Well Microdilution Plates | Sterile, U-bottom plates for housing the dilution series and inoculum. |

| Antimicrobial Reference Powders | High-purity, potency-certified powders for preparing stock solutions. |

| Multichannel Pipettes & Sterile Tips | For accurate and efficient transfer of inoculum across the plate. |

| Plate Sealing Film | Non-permeable adhesive film to prevent evaporation and contamination. |

| MIC Reading Mirror/Viewer | Aids in visualizing small amounts of growth or pellets in wells. |

Workflow and Pathway Visualizations

Title: M07 Broth Microdilution Core Workflow

Title: Critical Factors Influencing MIC Result Reliability

The Clinical and Laboratory Standards Institute (CLSI) M07 standard, “Methods for Dilution Antimicrobial Susceptibility Tests for Bacteria That Grow Aerobically,” is the definitive reference for broth microdilution (BMD) methods. Within a broader thesis on CLSI M07 method research, recent updates (2023-2024) refine critical procedural details, acceptance criteria, and quality control (QC) parameters to address emerging challenges in antimicrobial susceptibility testing (AST). This review synthesizes these technical revisions and their implications for research and drug development.

Key Quantitative Updates in M07 (2023-2024)

The following tables summarize the primary quantitative changes and clarifications introduced.

Table 1: Updated QC Ranges for Key Antimicrobial Agents

| Organism (QC Strain) | Antimicrobial Agent | Previous MIC Range (μg/mL) | Updated MIC Range (μg/mL) | CLSI Document Reference |

|---|---|---|---|---|

| E. coli ATCC 25922 | Cefiderocol | 0.03-0.12 | 0.015-0.06 | M100-Ed34 |

| P. aeruginosa ATCC 27853 | Ceftolozane-Tazobactam | 0.5-4 | 0.25-2 | M100-Ed34 |

| S. aureus ATCC 29213 | Delafloxacin | 0.008-0.03 | 0.004-0.015 | M100-Ed34 |

| E. faecalis ATCC 29212 | Daptomycin | 1-4 | 0.5-4 (Ca²⁺ adj.) | M100-Ed34 |

Table 2: Clarified Technical Specifications for BMD

| Parameter | Previous Guidance (Pre-2023) | Refined Guidance (2023-2024) |

|---|---|---|

| Inoculum Preparation (McFarland) | 0.5 McFarland standard | Emphasizes direct colony suspension and verification via colony count or photometric methods. |

| Incubation Time for Staphylococcus spp. | 16-20 hours | Specifies 20-24 hours for oxacillin and cefoxitin against S. aureus to ensure mecA expression. |

| Cation Adjustment for Daptomycin Testing | Mueller-Hinton Broth (MHB) with Ca²⁺ | Mandates final Ca²⁺ concentration of 50 µg/mL and provides detailed preparation protocol. |

| Quality Control Frequency | Daily (or with each run) | Allows for weekly QC if established criteria are met (≥30 consecutive days of acceptable results). |

Detailed Experimental Protocols

Updated Broth Microdilution for Daptomycin (Ca²⁺-Adjusted)

Objective: To determine the MIC of daptomycin against Enterococcus spp. and Staphylococcus spp. Methodology:

- Broth Preparation: Prepare Ca²⁺-adjusted MHB. Dissolve MHB powder in distilled water, autoclave, and cool. Aseptically add a sterile 1% CaCl₂ solution to achieve a final concentration of 50 µg/mL Ca²⁺. Verify concentration if needed.

- Antimicrobial Dilution: Prepare a stock solution of daptomycin in sterile water. Perform two-fold serial dilutions in the Ca²⁺-adjusted MHB across the 96-well microdilution tray (final volume: 50 µL/well).

- Inoculum Standardization: Using a direct colony suspension method, adjust a bacterial suspension to a 0.5 McFarland standard (~1-2 x 10⁸ CFU/mL). Dilute this suspension 1:100 in sterile saline or water, then further dilute 1:20 in Ca²⁺-adjusted MHB to achieve ~5 x 10⁵ CFU/mL.

- Inoculation: Add 50 µL of the adjusted inoculum to each well of the antimicrobial-containing tray. Final inoculum: ~2.5 x 10⁵ CFU/well. Include growth (antimicrobial-free) and sterility (broth-only) controls.

- Incubation & Reading: Seal tray and incubate aerobically at 35±2°C for 16-20 hours. The MIC is the lowest concentration that completely inhibits visible growth.

QC Procedure Using Weekly Monitoring Protocol

Objective: To implement the optional weekly QC testing after establishing performance. Methodology:

- Initial Daily QC: For a minimum of 30 consecutive test days, perform QC using appropriate ATCC strains (E. coli 25922, S. aureus 29213, etc.) with each batch of clinical or research isolates.

- Data Logging: Record all MIC results. All results for each drug-organism pair must fall within the published QC range for the 30-day period.

- Transition to Weekly QC: After successful validation, QC testing for that specific drug-organism-strain combination may be performed weekly. Each test run must still include the required growth controls.

- Failure Action: If any weekly QC result is out of range, revert to daily QC for that agent until the problem is identified, corrected, and another 30-day period of in-control results is documented.

Visualizing Key Methodological Updates

Title: Updated Broth Microdilution Inoculum Prep Workflow

Title: Decision Tree for QC Testing Frequency (CLSI M07)

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents and Materials for CLSI M07-Compliant BMD

| Item | Function/Brief Explanation |

|---|---|

| Cation-Adjusted Mueller-Hinton Broth (CAMHB) | Standardized growth medium containing optimal levels of Ca²⁺ and Mg²⁺ ions for AST. |

| Sterile 1% Calcium Chloride (CaCl₂) Solution | Used to supplement MHB to the precise 50 µg/mL final concentration required for reliable daptomycin MICs. |

| Frozen or Lyophilized Microdilution Panels | Pre-manufactured 96-well panels containing serial dilutions of antimicrobials, ensuring standardization and reproducibility. |

| Tryptic Soy Agar (TSA) or Blood Agar Plates | For sub-culture and preparation of pure, 18-24 hour old bacterial colonies for inoculum. |

| 0.5 McFarland Turbidity Standard | Reference for standardizing bacterial inoculum density either visually or via densitometer. |

| ATCC Quality Control Strains (e.g., E. coli 25922, S. aureus 29213) | Essential for validating the accuracy and precision of the test system as per CLSI guidelines. |

| Sterile Saline (0.85-0.9% NaCl) | For making bacterial suspensions and performing critical dilution steps. |

| Multichannel Pipettes (e.g., 50 µL volume) | Enables rapid, accurate, and reproducible inoculation of microdilution trays. |

| Microdilution Tray Sealing Film | Prevents evaporation and cross-contamination during the 16-24 hour incubation period. |

The Clinical and Laboratory Standards Institute (CLSI) M07 standard, formally titled "Methods for Dilution Antimicrobial Susceptibility Tests for Bacteria That Grow Aerobically," is the definitive reference broth microdilution (BMD) method for antimicrobial susceptibility testing (AST). Its global importance stems from its adoption and citation by major regulatory and standard-setting bodies, which use it to ensure the accuracy, reproducibility, and clinical relevance of AST data critical for drug development and patient care.

Table 1: M07 Citation in Global Guidelines

| Regulatory Body | Guideline Document | Primary Role of M07 | Status |

|---|---|---|---|

| U.S. FDA | Various Drug-Specific Guidance, e.g., "Acute Bacterial Skin and Skin Structure Infections: Developing Drugs for Treatment" | Defines the reference method for establishing in vitro susceptibility of drug candidates and for validating commercial AST devices. Cited for MIC determination of comparator agents. | Mandatory for regulatory submissions. |

| EUCAST | EUCAST Definitive Document (EDef) 3.1 & 7.1 (Method for MIC determination) | Forms the methodological basis. EUCAST has harmonized its BMD methodology with CLSI M07, with minor modifications (e.g., inoculum preparation, some media specifications). | Foundational. EUCAST describes its method as "based on" the CLSI standard. |

| CLSI | M07 (current edition: M07-A11/EUCAST 7.1) | The source document. Provides the comprehensive, detailed procedural standard for performing reference BMD. | The core standard. |

| Ph. Eur./USP | General Chapter 5.1.4 (Microbiological assay of antibiotics) & various monographs | Referenced as the standard method for determining minimum inhibitory concentrations (MICs) for potency assays and quality control. | Referenced standard. |

| Japanese PMDA | Various, including "Microbiological Data for Antimicrobial Products" | Recognized as an acceptable reference method for clinical trials and drug approval submissions. | Accepted standard. |

Core Methodological Protocols from CLSI M07

The following is a synthesized workflow of the critical experimental protocols defined in CLSI M07.

Protocol 1: Preparation of Antimicrobial Stock Solutions

- Purpose: To create standardized, high-concentration solutions of antimicrobial agents for subsequent dilution in microdilution trays.

- Materials: Analytical-grade antimicrobial powder, precise balance, appropriate solvent (as specified in M07 Table 6A), diluent (often sterile distilled water or buffer), sterile vials.

- Method:

- Calculate the required mass of powder to achieve a stock concentration of at least 1000 µg/mL (or higher, e.g., 5120 µg/mL).

- Dissolve the powder in the specified solvent. For poorly water-soluble drugs, a small volume of alternative solvent (e.g., dimethyl sulfoxide, acidic/basic buffer) may be used initially.

- Dilute to final volume with the appropriate diluent.

- Filter-sterilize (0.22 µm pore size) if not prepared aseptically.

- Aliquot and store at -70°C or below (unless stability data support less stringent conditions).

Protocol 2: Broth Microdilution Panel Preparation

- Purpose: To create a serial two-fold dilution series of the antimicrobial agent in cation-adjusted Mueller-Hinton Broth (CAMHB) within a 96-well microdilution tray.

- Materials: Antimicrobial stock solution, CAMHB, sterile 96-well trays, multichannel pipettes, automated dilutor/dispenser.

- Method:

- Prepare CAMHB according to manufacturer instructions. For testing Streptococcus pneumoniae or other fastidious organisms, supplement with 2.5-5% lysed horse blood.

- Using a multichannel pipette or automated system, dispense 50 µL of CAMHB into all wells of the tray.

- Add 50 µL of the antimicrobial stock solution to the first well (highest concentration).

- Serially dilute by transferring 50 µL from well 1 to well 2, mixing, and continuing across the plate. Discard 50 µL from the final well.

- The final volume in each well is 50 µL, containing the antimicrobial at the desired final concentration range (e.g., 64 to 0.03 µg/mL).

Protocol 3: Inoculum Preparation and Standardization

- Purpose: To prepare a standardized bacterial inoculum of approximately 5 x 10⁵ CFU/mL in the final test well.

- Materials: Fresh overnight bacterial culture on non-selective agar, sterile saline or broth, spectrophotometer, adjustable pipettes.

- Method (Direct Colony Suspension):

- Select 3-5 well-isolated colonies from an 18-24 hour agar plate.

- Suspend colonies in sterile saline or broth.

- Adjust the turbidity to a 0.5 McFarland standard using a spectrophotometer (optical density of 0.08-0.13 at 625 nm). This yields a suspension of ~1-2 x 10⁸ CFU/mL.

- Dilute this suspension 1:100 in sterile saline or water to create a "working suspension" of ~1-2 x 10⁶ CFU/mL.

- Further dilute this 1:20 by adding 10 µL to 190 µL of CAMHB in a tube or well. The final test inoculum is ~5 x 10⁵ CFU/mL in a total volume of 100 µL per well (50 µL drug + 50 µL inoculated broth).

Protocol 4: Inoculation, Incubation, and MIC Reading

- Purpose: To conduct the test and determine the Minimum Inhibitory Concentration (MIC).

- Materials: Prepared microdilution tray, standardized inoculum, multichannel pipette, sterile reservoir, incubator set to 35°C ± 2°C.

- Method:

- Add 50 µL of the standardized inoculum (from Protocol 3, step 4) to each well of the drug-containing microdilution tray. Use a growth control well (CAMHB + inoculum) and a sterility control well (CAMHB only).

- Seal the tray with a lid or adhesive seal.

- Incubate under ambient air at 35°C ± 2°C for 16-20 hours (standard organisms). Incubate S. pneumoniae and other fastidious organisms for 20-24 hours in ambient air.

- Read the MIC visually. The MIC is the lowest concentration of antimicrobial that completely inhibits visible growth as observed with the unaided eye.

Visualizing the Regulatory and Methodological Ecosystem

Diagram 1: M07 as the Foundational Hub for Global AST

Diagram 2: Core Broth Microdilution Experimental Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Research Reagents & Materials for M07-Compliant BMD

| Item | Function & Specification | Critical Notes |

|---|---|---|

| Cation-Adjusted Mueller Hinton Broth (CAMHB) | The standard medium for non-fastidious organisms. Contains controlled levels of Ca²⁺ and Mg²⁺ cations, which critically affect the activity of aminoglycosides and polymyxins. | Must meet lot-to-lot performance standards using CLSI QC strains. |

| CAMHB with Lysed Horse Blood (LHB) | Supplemented (2.5-5%) for testing fastidious organisms like S. pneumoniae, Haemophilus spp., and other streptococci. | Lysis removes inhibitors and provides necessary growth factors (X and V factors for Haemophilus). |

| Reference Antimicrobial Powders | High-purity, potency-certified powders for preparing in-house stock solutions. Used for investigational drug testing or validating commercial panels. | Source from reputable suppliers (e.g., USP, Sigma). Potency must be accounted for in concentration calculations. |

| Quality Control (QC) Strains | Frozen stocks of well-characterized strains (e.g., E. coli ATCC 25922, P. aeruginosa ATCC 27853, S. aureus ATCC 29213). | Used daily to verify the precision and accuracy of the entire test system (media, inoculum, drugs, incubation). |

| 96-Well Microdilution Trays | Sterile, non-pyrogenic, U-bottom or flat-bottom polystyrene trays. U-bottom is standard for easier visual reading. | Must be compatible with automated inoculators and readers if used. |

| McFarland Standards (0.5) | Provides the optical reference for standardizing the bacterial inoculum turbidity. Can be physical tubes or a calibrated densitometer. | Critical for achieving the target final inoculum of ~5 x 10⁵ CFU/mL. |

| Sterile Saline (0.85-0.9%) | Isotonic solution for suspending bacterial colonies and preparing inoculum dilutions. | Prevents osmotic shock to the bacterial cells during suspension. |

| Multichannel/Micro-volume Pipettes | For accurate, reproducible dispensing of small volumes (50-100 µL) of broth, drugs, and inoculum across 96-well plates. | Regular calibration is essential for data integrity. |

| Automated Plate Reader (Optional) | Spectrophotometric or imaging device to objectively determine MIC endpoints, improving reproducibility and enabling high-throughput. | Must be validated against visual reading per CLSI guidelines. |

Step-by-Step Protocol: Executing the CLSI M07 Broth Microdilution Method

The reliability of any antimicrobial susceptibility testing (AST) study hinges upon the foundational steps of reagent and stock solution preparation. Within the framework of CLSI standard M07 for broth microdilution method research, precision in these initial stages dictates the validity of Minimum Inhibitory Concentration (MIC) data, which informs critical decisions in drug development and resistance monitoring. This guide details the technical protocols and considerations essential for robust, reproducible research.

Core Reagent Preparation for Broth Microdilution

The growth medium must support robust growth of control organisms while not interfering with the antimicrobial's activity. Cation-adjusted Mueller Hinton Broth (CAMHB) is the standard medium specified by CLSI M07.

Protocol: Preparation of CAMHB

- Weigh the appropriate quantity of commercially available Mueller Hinton Broth powder as per manufacturer's instructions (typically 21g/L for the base broth).

- Dissolve in distilled or deionized water with gentle heating and stirring.

- Autoclave at 121°C for 15 minutes. Allow to cool to room temperature.

- Aseptically supplement with cations to achieve final concentrations of:

- Calcium (Ca²⁺): 20-25 mg/L (50-100 µM)

- Magnesium (Mg²⁺): 10-12.5 mg/L (20-50 µM)

- This is typically done using filter-sterilized stock solutions of CaCl₂ and MgCl₂.

- Adjust pH to 7.2-7.4 at room temperature using sterile acid or base. Verify pH after adjustment and storage.

Table 1: Critical Quality Control Parameters for CAMHB

| Parameter | Target Specification | Rationale & Impact |

|---|---|---|

| pH | 7.2 - 7.4 (at 25°C) | pH affects antimicrobial stability and activity (e.g., aminoglycosides more active at alkaline pH, tetracyclines at acidic pH). |

| Divalent Cations | Ca²⁺: 20-25 mg/L; Mg²⁺: 10-12.5 mg/L | Standardizes conditions; affects activity of aminoglycosides (enhanced by Mg²⁺) and tetracyclines (chelated by cations). |

| Thymidine/Thymine Content | Minimal to absent | Prevents antagonism of trimethoprim and sulfonamide activity. |

| Sterility | No growth after 72h incubation | Prevents contamination of test panels. |

| Performance Check | MICs for QC strains within published ranges | Validates the entire medium preparation system. |

Antimicrobial Stock Solution Preparation

Accurate stock solutions are paramount. Errors at this stage are multiplicative and invalidate subsequent dilutions.

Protocol: Standard Preparation of a 1280 µg/mL (or 2560 µg/mL) Primary Stock

- Calculate Mass: Determine the mass of antimicrobial powder required using the formula: Mass (mg) = (Desired Concentration (µg/mL) * Desired Volume (mL)) / Potency (µg/mg). Potency is specific to each batch, as stated on the Certificate of Analysis.

- Weighing: Use an analytical balance (minimum 4 decimal places) in a controlled environment. Pre-weigh an appropriate vessel to correct for tare weight.

- Solubilization: Dissolve the powder in the correct solvent (see Table 2). Vortex or sonicate as needed.

- Dilution to Final Volume: Transfer to a volumetric flask and dilute to the final mark with the appropriate diluent (often sterile water or buffer). Mix thoroughly.

- Aliquoting & Storage: Aseptically aliquot into sterile, tightly sealed vials. Label with compound name, concentration, date, batch number, and storage conditions. Store per stability data (typically ≤ -60°C for long-term).

Table 2: Common Solvents and Diluents for Antimicrobial Stock Solutions

| Antimicrobial Class | Recommended Solvent | Primary Diluent | Stability Considerations (Approx.) |

|---|---|---|---|

| β-lactams (Penicillins, Cephalosporins) | Phosphate Buffer (pH 6.0, 0.1M) | Sterile Water or Buffer | Unstable; prepare fresh weekly; store at -60°C or below. |

| Aminoglycosides | Sterile Water or Phosphate Buffer | Sterile Water | Stable for 1 year at -60°C; avoid repeated freeze-thaw. |

| Fluoroquinolones | Water with 0.1N NaOH (if needed) | Sterile Water | Stable for 1 year at -60°C. |

| Macrolides | Methanol or Ethanol (small volume) | Sterile Water | Stable for 1 year at -60°C; ensure ethanol ≤1% final in test. |

| Tetracyclines | Water with 0.1N HCl (if needed) | Sterile Water | Light sensitive; stable for 1 year at -60°C in dark. |

| Glycopeptides (Vancomycin) | Sterile Water | Sterile Water | Stable for 1 year at -60°C. |

| Azoles (Fluconazole) | Sterile Water | Sterile Water | Stable for 1 year at -60°C or 6 months at -20°C. |

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| Analytical Balance (0.0001g) | Precise weighing of antimicrobial powders is non-negotiable for accurate stock concentrations. |

| Certified Reference Standard Powder | High-purity antimicrobial with a known potency and assigned expiry date, traceable to a national/international standard. |

| pH Meter (Calibrated) | Ensures CAMHB and any buffers are within the strict pH range (7.2-7.4) required by CLSI M07. |

| Class A Volumetric Glassware | Provides the highest accuracy for preparing standard solutions and final broth volumes. |

| Sterile, Low-Binding Microcentrifuge Tubes & Vials | For aliquoting and storing stock solutions to prevent adsorption to container walls and maintain sterility. |

| Ultra-Low Temperature Freezer (≤ -60°C) | For long-term storage of stock solutions to maintain antimicrobial stability. |

| Solvent Filter Units (0.22 µm) | For sterilizing solvents, diluents, and cation supplements that cannot be autoclaved. |

| QC Strain Panels | Frozen stocks of reference strains (e.g., E. coli ATCC 25922, S. aureus ATCC 29213) for validating medium and test performance. |

Workflow and Quality Control Integration

AST Reagent Preparation and QC Workflow

Detailed Broth Microdilution Panel Preparation Protocol

Protocol: Two-Fold Serial Dilution in 96-Well Trays

- Thaw Stock: Thaw the primary antimicrobial stock solution (e.g., 2560 µg/mL) and warm to room temperature. Vortex briefly.

- Prepare Intermediate Dilution: In a sterile tube, dilute the primary stock in CAMHB to create an intermediate concentration that is twice the desired highest test concentration (e.g., for a high test concentration of 64 µg/mL, prepare 128 µg/mL in 10 mL CAMHB).

- Panel Loading: Aseptically add 100 µL of CAMHB to all wells of a sterile 96-well tray (columns 2-12).

- Serial Dilution: Add 100 µL of the intermediate antimicrobial solution to all wells of column 1. Perform a two-fold serial dilution by transferring 100 µL from column 1 to column 2, mixing thoroughly, then from column 2 to column 3, and so on through column 11. Discard 100 µL from column 11. Column 12 serves as the growth control (no antimicrobial).

- Inoculum Addition: Prepare a standardized bacterial inoculum of 5 x 10⁵ CFU/mL in CAMHB. Add 100 µL of this inoculum to each well of columns 1-11. Add 100 µL of inoculated broth to column 12. This results in a final volume of 200 µL/well and a final antimicrobial concentration range (e.g., 64, 32, 16,... µg/mL) with ~5 x 10⁵ CFU/mL.

- Incubation: Seal the tray and incubate at 35±2°C for 16-20 hours (as per organism and CLSI guidelines).

- MIC Determination: The MIC is the lowest concentration of antimicrobial that completely inhibits visible growth.

Adherence to these critical first steps in reagent and stock solution preparation establishes the foundation for generating data that is precise, reproducible, and compliant with the rigorous standards of CLSI M07, ultimately driving meaningful research in antimicrobial drug development.

Within the framework of CLSI standard M07 for broth microdilution antimicrobial susceptibility testing, accurate inoculum preparation is the critical first step. The reliability of Minimum Inhibitory Concentration (MIC) endpoints depends entirely on the precision of the initial bacterial inoculum. This guide details the technical procedures for achieving a standardized 0.5 McFarland suspension and performing the subsequent dilutions required for testing, as mandated by CLSI M07.

The 0.5 McFarland Standard: Principles and Specifications

The McFarland standard is a turbidity benchmark. A 0.5 McFarland standard provides a reproducible optical density corresponding to a known approximate cell density, essential for creating a consistent starting inoculum.

Table 1: McFarland Standard Specifications

| McFarland Standard | Approximate Bacterial Density (CFU/mL) | % Transmittance | Absorbance (625 nm) |

|---|---|---|---|

| 0.5 | 1.5 x 10^8 | 74.3 - 77.4 | 0.08 - 0.13 |

| 1.0 | 3.0 x 10^8 | 55.6 - 60.2 | 0.22 - 0.27 |

| 2.0 | 6.0 x 10^8 | 35.0 - 40.7 | 0.39 - 0.46 |

CFU: Colony Forming Units. Data sourced from current CLSI M07 guidelines and instrument manuals.

Core Experimental Protocol: Inoculum Preparation per CLSI M07

Direct Colony Suspension Method (Primary Method)

Objective: To prepare a bacterial suspension directly from isolated colonies, adjusted to a 0.5 McFarland standard.

Materials: See "The Scientist's Toolkit" below. Procedure:

- Select 3-5 well-isolated, morphologically identical colonies from an 18-24 hour agar plate.

- Using a sterile loop or swab, transfer the colonies to a tube containing 4-5 mL of sterile saline (0.85% NaCl) or Mueller-Hinton Broth.

- Vortex the suspension vigorously for 15-20 seconds to achieve a homogeneous, clump-free suspension.

- Adjust the turbidity: a. Using a densitometer: Measure and add broth or saline until the reading is 0.08-0.13 at 625 nm. b. Using visual comparators: Compare against a 0.5 McFarland standard under appropriate lighting against a white background with a contrasting black line.

- Critical: The adjusted suspension must be used within 15 minutes of preparation.

Inoculum Dilution for Broth Microdilution

Objective: To dilute the 0.5 McFarland suspension to the final testing inoculum of approximately 5 x 10^5 CFU/mL.

Procedure:

- Perform a 1:150 dilution of the adjusted 0.5 McFarland suspension into cation-adjusted Mueller-Hinton Broth (CAMHB).

- Example: Add 0.1 mL of suspension to 14.9 mL of CAMHB (or proportionally smaller volumes).

- This yields a "turbidity-adjusted inoculum" with a target density of ~1 x 10^6 CFU/mL.

- Dispense this diluted inoculum into the wells of a microdilution tray. The act of adding an equal volume of this inoculum to wells containing an equal volume of 2X drug solution (or broth for growth control) results in a final 1:2 dilution.

- Final Result: Each test well contains ~5 x 10^5 CFU/mL in a total volume of 100 µL (typical).

Table 2: Dilution Scheme for Broth Microdilution

| Step | Suspension | Diluent | Dilution Factor | Approximate CFU/mL |

|---|---|---|---|---|

| 1 | Colonies | Saline | N/A | Adjusted to 1.5 x 10^8 |

| 2 | 0.5 McFarland | CAMHB | 1:150 | 1 x 10^6 |

| 3 | Diluted Inoculum | 2X Drug in Well | 1:2 (Final) | 5 x 10^5 |

Quality Control and Validation

- Purity Check: Subculture the adjusted suspension to confirm purity.

- Quantitative Verification: Perform colony counts on the final diluted inoculum. Plate 10 µL of the 1:150 dilution onto an agar plate. After incubation, the number of colonies x 100 = CFU/mL in the diluted inoculum. Target: 0.5 - 2 x 10^6 CFU/mL.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Inoculum Standardization

| Item | Function | Key Specifications |

|---|---|---|

| Cation-Adjusted Mueller-Hinton Broth (CAMHB) | Standardized growth medium for susceptibility testing. | Contains controlled levels of Ca2+ and Mg2+ ions as per CLSI. |

| Sterile 0.85% Saline | Suspension fluid for initial colony suspension. | Isotonic to prevent osmotic shock to bacterial cells. |

| McFarland Standards (0.5) | Primary turbidity reference. | Sealed tubes or latex particle suspensions; replaced periodically. |

| Turbidity Densitometer | Instrument for precise optical density measurement. | Wavelength: 625 nm; requires regular calibration. |

| Sterile Polystyrene Tubes | For preparing and adjusting suspension. | Non-inhibitory, clear for turbidity reading. |

| Digital Dispensers/Pipettes | For accurate volume transfers during dilution. | Calibrated regularly; capable of dispensing 10 µL - 10 mL. |

| Vortex Mixer | To create homogenous bacterial suspensions. | Must provide sufficient agitation to break up clumps. |

Visualized Workflows

The Clinical and Laboratory Standards Institute (CLSI) document M07, "Methods for Dilution Antimicrobial Susceptibility Tests for Bacteria That Grow Aerobically," serves as the authoritative protocol for broth microdilution (BMD) testing. A cornerstone of the method's reproducibility and clinical relevance is the precise establishment of the drug dilution series and appropriate controls within the microdilution tray. This whitepaper details the technical execution of this critical step, providing an in-depth guide for researchers and drug development professionals to ensure data integrity, support antibiotic discovery, and generate results compliant with CLSI M07 standards.

Core Principles: Drug Dilution Series Design

The BMD method quantifies the Minimum Inhibitory Concentration (MIC) by testing a series of drug concentrations against a standardized bacterial inoculum. The series is typically a two-fold serial dilution, yielding a concentration range that brackets the expected MIC of target organisms.

Quantitative Parameters for Drug Preparation

Stock Solution Preparation: A primary stock solution of the test antimicrobial agent is prepared at a high concentration (e.g., 1280 µg/mL or 10× the highest test concentration). Solubility, stability, and solvent choice must be justified and documented per CLSI M07 guidelines. Appropriate safety data sheets (SDS) must be consulted.

Dilution Series Calculation: The final test concentrations in the broth are achieved through a serial dilution workflow. The following table summarizes a standard 96-well plate layout for a single antimicrobial agent.

Table 1: Example Two-Fold Serial Dilution Scheme for a 96-Well Plate

| Well Row | Dilution Step | Volume Transfer | Diluent Volume | Relative Final Concentration (µg/mL) | Purpose |

|---|---|---|---|---|---|

| A1-A12 | Primary Stock | N/A | N/A | 128 (Highest) | Test series start |

| B1-B12 | 1:2 from Row A | 100 µL → | 100 µL | 64 | Two-fold dilution |

| C1-C12 | 1:2 from Row B | 100 µL → | 100 µL | 32 | Two-fold dilution |

| D1-D12 | 1:2 from Row C | 100 µL → | 100 µL | 16 | Two-fold dilution |

| E1-E12 | 1:2 from Row D | 100 µL → | 100 µL | 8 | Two-fold dilution |

| F1-F12 | 1:2 from Row E | 100 µL → | 100 µL | 4 | Two-fold dilution |

| G1-G12 | 1:2 from Row F | 100 µL → | 100 µL | 2 | Two-fold dilution |

| H1-H12 | 1:2 from Row G | 100 µL → | 100 µL | 1 (Lowest) | Test series end |

Note: After final transfer, 100 µL is discarded from the last row (H) to maintain equal volumes. The actual concentration values are example placeholders.

Essential Controls in BMD per CLSI M07

Controls validate the entire test system. Their inclusion is non-negotiable for CLSI-compliant research.

Table 2: Mandatory and Recommended Controls for BMD Trays

| Control Type | Well Position Example | Composition | Acceptable Result | Function |

|---|---|---|---|---|

| Growth Control | Column 11, All Rows | Broth + Inoculum (No drug) | Visible Growth | Confirms organism viability and adequate incubation. |

| Sterility Control | Column 12, All Rows | Broth Only (No drug, No inoculum) | No Growth | Confirms media sterility and aseptic technique. |

| Solvent Control | As Needed | Broth + Inoculum + Max [Solvent] | Growth equal to Growth Control | Rules out solvent toxicity. |

| Reference Strain Control | Separate Tray/Plate | Broth + QC Strain + Drug Series | MIC within published QC range | Verifies drug potency and procedure accuracy. |

Detailed Experimental Protocol: Tray Setup

Protocol 1: Manual Preparation of Drug Dilution Series in a 96-Well Tray Materials: Sterile 96-well U-bottom microtiter plate, multichannel pipettes, sterile reservoirs, antimicrobial stock solution, cation-adjusted Mueller-Hinton Broth (CAMHB), sterile pipette tips. Procedure:

- Labeling: Label the plate with drug name, date, batch, and organism identifiers.

- Diluent Addition: Using a multichannel pipette, add 100 µL of CAMHB to wells B12 through H12 (sterility control column) and wells B1 through H11 (all test columns except the first row).

- Initial Drug Addition: Add 200 µL of the prepared antimicrobial stock solution to wells A1 through A11.

- Serial Dilution: Mix the contents of row A thoroughly. Transfer 100 µL from row A to row B. Mix row B thoroughly. Continue this two-fold serial dilution through row G, transferring 100 µL each time.

- Final Volume Adjustment: After mixing row G, transfer 100 µL from row G to row H. Mix row H and discard 100 µL from row H to leave a final volume of 100 µL in all wells.

- Inoculum Addition: Prepare a 0.5 McFarland standard suspension of the test organism and dilute it in CAMHB to achieve a final inoculum of ~5 × 10⁵ CFU/mL. Using a multichannel pipette, add 100 µL of this adjusted inoculum to all wells in columns 1-11 (drug and growth control wells).

- Sterility Control Setup: Add 100 µL of sterile CAMHB (no inoculum) to all wells in column 12.

- Incubation: Cover the plate, place it in a sealed container or plastic bag to prevent evaporation, and incubate aerobically at 35 ± 2 °C for 16-20 hours as per CLSI M07.

Protocol 2: Using Pre-prepared, Frozen Microdilution Trays Materials: Commercially prepared or laboratory-made frozen trays, water bath at 35-40°C, calibrated inoculum delivery system. Procedure:

- Thawing: Remove tray from frozen storage (-70°C or lower) and thaw at room temperature or in a 35-40°C water bath for ≤30 minutes.

- Drying: Place the thawed tray in a laminar flow hood with the lid slightly ajar for 10-15 minutes to eliminate condensation on the lid.

- Inoculation: Following CLSI M07 inoculum preparation standards, use a replicator or multichannel pipette to deliver 0.005-0.01 mL (5-10 µL) of the adjusted inoculum (~5 × 10⁵ CFU/mL) directly onto the surface of the broth in each well. This results in a 1:10 to 1:20 final dilution.

- Mixing: Gently tap or vortex the tray to mix.

- Incubation: Incubate as described in Protocol 1, Step 8.

Visualization: BMD Tray Setup and Testing Workflow

Diagram Title: Broth Microdilution Tray Setup and Testing Workflow

Diagram Title: 96-Well Plate Layout for MIC Testing and Controls

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for BMD Tray Setup

| Item | Function | Technical Specification / Notes |

|---|---|---|

| Cation-Adjusted Mueller-Hinton Broth (CAMHB) | Standardized growth medium for susceptibility testing. | Must contain Ca²⁺ (20-25 mg/L) and Mg²⁺ (10-12.5 mg/L) as per CLSI M07. Ensures reproducible cation-dependent drug activity (e.g., aminoglycosides, polymyxins). |

| Sterile, U-Bottom 96-Well Microtiter Plates | Reaction vessel for the dilution series and incubation. | Polystyrene, non-tissue-culture-treated. U-bottom facilitates pellet formation for clear visual endpoint reading. Must be lid-compatible to prevent evaporation. |

| Precision Multichannel Pipettes | Enables accurate, high-throughput liquid handling for serial dilutions and inoculation. | Typically 8- or 12-channel, volumes 1-50 µL and 30-300 µL. Regular calibration is essential for volumetric accuracy. |

| McFarland Standard (0.5) | Visual or densitometric reference for standardizing bacterial inoculum density. | Corresponds to ~1-2 x 10⁸ CFU/mL for E. coli. Use commercial latex standards or a calibrated densitometer for accuracy. |

| Quality Control (QC) Strains | Validates drug potency and procedural accuracy. | CLSI M07 specifies strains (e.g., S. aureus ATCC 29213, P. aeruginosa ATCC 27853). Their MICs must fall within published QC ranges. |

| Sterile Dilution Buffers/Solvents | For solubilizing antimicrobial agents. | Common solvents include sterile water, dimethyl sulfoxide (DMSO), or specific pH buffers. Must be validated for non-interference with bacterial growth. |

| Automated Plate Inoculation System (e.g., replicator) | Alternative to manual pipetting for high-throughput studies. | Delivers a precise, small volume (5-10 µL) of inoculum simultaneously to all wells, improving speed and reproducibility. |

| Plate Sealing Film or Humidified Chamber | Prevents evaporation during incubation. | Critical for maintaining well volume and drug concentration over the 16-20 hour incubation period. |

Incubation Conditions, Timing, and Environmental Controls

The Clinical and Laboratory Standards Institute (CLSI) document M07, "Methods for Dilution Antimicrobial Susceptibility Tests for Bacteria That Grow Aerobically," is the definitive standard for broth microdilution (BMD) testing. While M07 defines critical procedural parameters, the optimization of incubation conditions, timing, and environmental controls remains a focal point of ongoing research. This whitepaper delves into the technical nuances of these variables, framed within the broader thesis that precise, reproducible, and clinically predictive BMD results are contingent upon strict, evidence-based incubation protocols beyond the foundational M07 guidelines. For drug development professionals and researchers, mastering these elements is paramount for generating robust data for novel antimicrobial agents and understanding resistance mechanisms.

Core Incubation Parameters: A Quantitative Analysis

The standard incubation conditions per CLSI M07 (11th Edition, 2018) for non-fastidious aerobic bacteria are 35°C ± 1°C in ambient air for 16-20 hours. However, research into specific organism-antimicrobial combinations and resistance phenotypes necessitates deviations and precise controls.

Table 1: Standard and Research-Based Incubation Conditions

| Organism Category | Temperature (°C) | Atmosphere | Duration (Hours) | Rationale & Research Context |

|---|---|---|---|---|

| Non-fastidious Aerobes (Standard) | 35 ± 1 | Ambient Air | 16-20 | CLSI M07 baseline. Critical for reproducibility of MIC endpoints. |

| Staphylococcus spp. (MRSA detection) | 35 ± 1 | Ambient Air | Full 24 | Research indicates ≤20h may miss inducible resistance (e.g., mecA). Essential for cefoxitin screening. |

| Streptococcus pneumoniae & Viridans Group | 35 ± 1 | 5% CO₂ | 20-24 | Enhanced growth in CO₂. CO₂ can acidify media, affecting aminoglycoside/tetracycline MICs. Must be controlled. |

| Haemophilus influenzae | 35 ± 1 | 5% CO₂ | 20-24 | Standard for fastidious organisms. Requires HTM broth, validated for CO₂ incubation. |

| Neisseria gonorrhoeae | 35 ± 1 | 5% CO₂ | 20-24 | CO₂ essential. Use GC agar base supplement. Duration may extend for some antimicrobials. |

| Non-tuberculous Mycobacteria (e.g., M. avium) | 30-35 (species-dependent) | Ambient Air | 3-7 days (up to 14) | Research area: Slow growth requires extended incubation. Temperature optima vary. Mueller-Hinton broth with OADC enrichment. |

| Carbapenemase-Producing Enterobacterales (CPE) | 35 ± 1 | Ambient Air | 16-20 + Reading at 4h/8h | Early-read studies for rapid phenotypic detection (e.g., colorimetric methods) alongside standard MIC. |

Environmental Controls & Their Impact on MIC

Temperature Uniformity and Calibration

A deviation of >1°C can significantly alter bacterial growth kinetics and MIC results. Research-grade incubators must have:

- Continuous Monitoring: Data-logging probes independent of incubator display.

- Mapping Studies: Validation of temperature uniformity across all shelf positions.

- Calibration: Traceable to national standards, performed at least annually.

Atmospheric Composition

- CO₂ Incubation: Lowers pH of unbuffered media (e.g., standard Mueller-Hinton Broth). This can increase MICs of aminoglycosides, macrolides, and tetracyclines, and decrease MICs of beta-lactams. CLSI-approved media for CO₂ incubation (e.g., CAMHB with TES buffer) mitigates this.

- Humidity: High humidity (>95%) is maintained in CO₂ incubators to prevent evaporation from microdilution wells, which can falsely elevate antimicrobial concentration and MIC.

Timing and Endpoint Determination

The incubation duration is intrinsically linked to the defined MIC endpoint: the lowest concentration that inhibits visible growth after a specified time.

- Early Reading: Research protocols for rapid resistance detection may use spectrophotometric or fluorometric readings at 4-8 hours, correlating to standard 16-20h MICs.

- Late Reading (>20h): Risks "skipped wells" or trailing endpoints, particularly with bacteriostatic agents. M07 advises against over-incubation but mandates it for specific agents (e.g., Staphylococcus with cefoxitin).

Detailed Experimental Protocols from Key Research

Protocol 1: Evaluating Incubation Time on Inducible Resistance Detection (e.g., MRSA)

Objective: To determine the optimal incubation time for reliable detection of methicillin-resistant Staphylococcus aureus (MRSA) using cefoxitin in BMD. Methodology:

- Strains: Use a panel of 50 S. aureus strains, including 20 confirmed MRSA (mecA+), 25 MSSA (mecA-), and 5 borderline oxacillin-resistant S. aureus (BORSA).

- Inoculum & Plating: Prepare 0.5 McFarland suspension in saline, dilute in CAMHB to achieve ~5x10⁵ CFU/mL. Aliquot 100 µL per well into a custom cefoxitin panel (range: 0.25-16 µg/mL).

- Incubation: Place panels in ambient air incubator at 35°C ± 0.5°C.

- Reading:

- Read MICs (complete inhibition) at 16h, 18h, 20h, 22h, and 24h.

- Record any well with >80% growth inhibition.

- Analysis: Compare MRSA detection rates (MIC ≥4 µg/mL) at each time point against mecA PCR as gold standard. Calculate sensitivity and specificity.

Protocol 2: Assessing CO₂-Induced MIC Shifts for Aminoglycosides

Objective: To quantify the effect of 5% CO₂ incubation on gentamicin MICs for Pseudomonas aeruginosa. Methodology:

- Media: Prepare two sets of BMD panels: Standard CAMHB and CAMHB buffered with 25mM TES.

- Strains: 30 clinical isolates of P. aeruginosa.

- Inoculum: Standardized per CLSI M07.

- Incubation Conditions: Duplicate panels are incubated in:

- Condition A: Ambient Air, 35°C.

- Condition B: 5% CO₂, 35°C. Both for 16-20h.

- Measurement & Analysis:

- Read MICs visually.

- Measure final pH of one control well per panel using a micro-pH electrode.

- Determine essential agreement (EA) and categorical agreement (CA) between conditions. A >2-fold MIC increase in CO₂ is significant.

Visualization of Experimental Workflows

Diagram 1: Comparative Incubation Condition Study Workflow

Diagram 2: CLSI M07 Incubation Timing Decision Logic

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for Incubation Condition Research

| Item | Function in Research | Technical Notes |

|---|---|---|

| Cation-Adjusted Mueller-Hinton Broth (CAMHB) | Standard medium for BMD of non-fastidious aerobes. Provides consistent cation levels (Ca²⁺, Mg²⁺) critical for aminoglycoside/polymyxin testing. | Must be validated for CO₂ incubation if used; often supplemented with TES buffer. |

| TES Buffer (N-Tris[Hydroxymethyl]methyl-2-aminoethanesulfonic acid) | Biological buffer added to CAMHB (20-25mM) to stabilize pH during incubation in CO₂ atmospheres. | Prevents false-high MICs for pH-sensitive drugs. Essential for reliable CO₂ studies. |

| HTM Broth (Haemophilus Test Medium) | Enriched medium for H. influenzae susceptibility testing. Contains NAD, hematin, and yeast extract. | Validated for incubation in 5% CO₂ per CLSI. |

| GC Broth Base with Supplement | For N. gonorrhoeae BMD. Requires IsoVitaleX or similar growth supplement. | CO₂ incubation is mandatory. |

| Precision Data-Logging Thermometer/Hygrometer | To continuously monitor and validate incubator temperature and humidity uniformity. | Independent probe(s) placed in liquid-filled flask simulate microplate conditions. |

| Microtiter Plate Reader (Spectrophotometric/Fluorometric) | For objective, high-throughput MIC reading and early-timepoint kinetic studies. | Allows research into rapid phenotypic resistance detection (e.g., carbapenemase activity). |

| pH Micro-Electrode | To measure final pH in control wells after incubation, quantifying CO₂-induced media acidification. | Confirms buffer capacity and identifies pH-related MIC outliers. |

Within the framework of CLSI M07 standard method research for broth microdilution, the determination of the Minimum Inhibitory Concentration (MIC) remains the definitive quantitative measure of antimicrobial susceptibility. The endpoint, the lowest concentration that inhibits visible growth, can be interpreted through two primary modalities: traditional visual reading and automated instrument reading. This technical guide examines the methodologies, validation criteria, and comparative performance of these two approaches, providing a detailed protocol for researchers and drug development professionals.

Core Methodologies and Protocols

Visual Reading Protocol (CLSI M07 Reference Method)

Principle: Trained technologists observe microdilution wells under controlled lighting against a non-reflective background.

- Panel Preparation: Prepare cation-adjusted Mueller-Hinton broth (CAMHB) according to CLSI M07. Dispense serial two-fold dilutions of antimicrobial agent into a 96-well microtiter plate.

- Inoculum Standardization: Adjust microbial suspension to a 0.5 McFarland standard (~1-5 x 10^8 CFU/mL). Further dilute in broth to achieve a final inoculum of ~5 x 10^5 CFU/mL in each well.

- Incubation: Incubate plates at 35°C ± 2°C in ambient air for 16-20 hours (standard bacteria; some fastidious organisms require extended time or specific conditions).

- Visual Endpoint Determination: Examine each well. The MIC is the lowest concentration where there is no visible growth, indicated by a clear well or a barely visible button of cells. Use an inverted reading mirror for enhanced visualization. Growth control must show turbidity, and sterility control must remain clear.

Automated Reading Protocol

Principle: Instruments determine optical density (OD) or turbidimetric measurements to calculate growth inhibition.

- Panel Preparation & Inoculation: Identical to visual method (Steps 1-3 above). Commercially prepared panels are often used.

- Instrument Calibration: Calibrate the automated reader (e.g., Sensititre Vizion, MicroScan, Vitek 2) using manufacturer-defined standards and control organisms.

- Automated Scanning: The reader scans each well at a specified wavelength (e.g., 405-660 nm depending on system). It measures OD for each well.

- Algorithmic Endpoint Determination: Proprietary software compares the OD of test wells to growth control wells. A threshold (e.g., ≥90% inhibition) is applied to determine the MIC. The software flags results requiring visual verification (e.g., skipped wells, trailing endpoints).

Comparative Performance Data

Table 1: Essential Criteria for MIC Endpoint Determination

| Criterion | Visual Reading | Automated Reading |

|---|---|---|

| Primary Detection Signal | Human eye perception of turbidity | Photometric absorbance/turbidity |

| Endpoint Threshold | No visible growth (subjective, trained eye) | Pre-defined % inhibition (e.g., ≥90%) |

| Read Time per Plate | 1-2 minutes | < 30 seconds |

| Susceptibility to Trailing | Manual assessment of slight growth across dilutions | Algorithmic interpretation, may require overrides |

| Essential Quality Control | Technologist competency testing, control strains | Daily instrument calibration, control strains |

Table 2: Agreement Rates Between Visual and Automated Methods (Representative Data)

| Organism Group (n studies) | Essential Agreement (% within ±1 dilution) | Categorical Agreement (%) | Major Error Rate (%) |

|---|---|---|---|

| Enterobacterales (3) | 95.2 - 98.7 | 97.1 - 99.0 | 0.1 - 0.5 |

| Non-fermenters (2) | 92.5 - 96.0 | 94.8 - 97.2 | 0.3 - 1.2 |

| Gram-positive Cocci (3) | 94.8 - 98.1 | 96.5 - 98.8 | 0.2 - 0.8 |

| Fastidious Organisms (2) | 90.1 - 94.3 | 92.0 - 95.5 | 0.5 - 1.5 |

Essential Agreement: MICs agree within ±1 two-fold dilution. Categorical Agreement: Interpretive category (S/I/R) matches. Major Error: False-resistant result.

Signaling and Decision Pathways

Diagram Title: MIC Endpoint Determination Workflow: Visual vs. Automated Pathways

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Broth Microdilution MIC Studies

| Item | Function & Specification |

|---|---|

| Cation-Adjusted Mueller-Hinton Broth (CAMHB) | Standard medium for non-fastidious aerobes; divalent cation adjustment ensures consistency in tetracycline/aminoglycoside activity. |

| Sterile 96-Well Microtiter Plates | U-bottom or flat-bottom plates for holding broth dilutions and inoculum. Must be non-cytotoxic and compatible with reader. |

| Antimicrobial Agent Stock Solutions | High-purity reference powders dissolved in appropriate solvent (water, DMSO, ethanol) per CLSI M100. |

| Turbidity Standard (0.5 McFarland) | Pre-made latex suspension or densitometer to standardize inoculum density to ~1.5 x 10^8 CFU/mL. |

| Multichannel & Automated Pipettes | For accurate, high-throughput transfer of broth, antimicrobials, and inoculum. |

| Automated MIC Reader (e.g., Sensititre Vizion) | Photometric instrument for measuring well turbidity; includes software for MIC calculation. |

| Quality Control Strains | CLSI-recommended strains (e.g., E. coli ATCC 25922, P. aeruginosa ATCC 27853) for daily validation of test conditions. |

| Inverted Reading Mirror & Light Box | Essential for visual reading; provides uniform, glare-free background to assess well turbidity. |

Validation and Quality Assurance Protocol

To validate an automated system against the reference visual method per CLSI guidelines:

- Strain Selection: Test a panel of 100-300 recent clinical isolates, encompassing target species and resistance phenotypes.

- Parallel Testing: Inoculate identical panels from the same preparation. Incubate and read one set visually (by two independent readers, blinded) and one set by the automated system.

- Data Analysis: Calculate essential agreement (EA) and categorical agreement (CA). Investigate all discrepancies (major/very major errors) by repeat testing using both methods and reference broth macrodilution if needed.

- Acceptance Criteria: For FDA/CLSI validation, EA should be ≥90% for non-fastidious organisms, with CA ≥90% and major error rates <3%.

This whitepaper provides an in-depth technical guide for determining the Minimum Inhibitory Concentration (MIC) of novel antimicrobial compounds, a cornerstone of in vitro efficacy assessment in drug development. The content is explicitly framed within the ongoing research and validation context of the Clinical and Laboratory Standards Institute (CLSI) standard M07, "Methods for Dilution Antimicrobial Susceptibility Tests for Bacteria That Grow Aerobically." Mastery of this standardized broth microdilution method is critical for generating reproducible, reliable, and clinically predictive data that can bridge the gap between early discovery and clinical trials.

The MIC is defined as the lowest concentration of an antimicrobial agent that completely inhibits visible growth of a microorganism under defined in vitro conditions. For novel compounds, establishing a baseline of activity against reference strains is the first critical step. The following table summarizes typical MIC data for control agents against CLSI-recommended quality control strains, which must be included in every run to validate the procedure.

Table 1: CLSI QC Ranges for Reference Antimicrobials (Broth Microdilution, CAMHB)

| QC Strain (ATCC #) | Antimicrobial | QC MIC Range (µg/mL) | Purpose in Novel Compound Testing |

|---|---|---|---|

| Staphylococcus aureus 29213 | Oxacillin | 0.12 - 0.5 | Control for β-lactamase stability |

| Escherichia coli 25922 | Ciprofloxacin | 0.004 - 0.016 | Control for fluoroquinolone/DNA gyrase targeting |

| Pseudomonas aeruginosa 27853 | Tobramycin | 0.5 - 2 | Control for aminoglycoside/efflux pump activity |

| Enterococcus faecalis 29212 | Vancomycin | 1 - 4 | Control for cell wall synthesis inhibition |

Table 2: Example MIC Data Interpretation for a Novel Compound

| Result Pattern | MIC (µg/mL) vs. QC Strain | Interpretation & Action |

|---|---|---|

| Within QC Range | Ciprofloxacin vs. E. coli 25922 = 0.008 | Run Valid. Novel compound data is reliable. |

| Out of QC Range | Ciprofloxacin vs. E. coli 25922 = 0.5 | Run Invalid. Investigate media, inoculation, compound stability. |

| Novel Compound Result | Novelexocin vs. S. aureus 29213 = 2.0 | Potency Benchmark. Compare to standard-of-care agents. |

Detailed Experimental Protocol: CLSI M07 Broth Microdilution

Protocol Title: Determination of MIC for a Novel Compound Against Aerobic Bacteria

1. Preparation of Antimicrobial Stock Solution:

- Weigh the novel compound precisely using an analytical balance.

- Dissolve in the appropriate solvent (e.g., DMSO, water, 0.1N NaOH/HCl) as per stability data to create a primary stock solution (e.g., 5120 µg/mL). Filter-sterilize (0.22 µm pore size).

- Prepare a working stock in sterile water or CAMHB at 10x the highest final test concentration.

2. Preparation of Microdilution Trays:

- Using a multichannel pipette, dispense 50 µL of cation-adjusted Mueller-Hinton broth (CAMHB) into each well of a sterile 96-well plastic tray (rows A-G, columns 1-12).

- Add 100 µL of the novel compound working stock to the first well of the designated row (e.g., column 1).

- Perform two-fold serial dilutions: Transfer 50 µL from column 1 to column 2, mix thoroughly, and continue through column 11. Discard 50 µL from column 11. Column 12 serves as the growth control (broth + inoculum, no drug).

3. Preparation of Inoculum:

- Streak the test organism from a frozen stock onto a non-selective agar plate. Incubate to obtain isolated colonies.

- Select 3-5 colonies to suspend in saline or broth. Adjust the turbidity to a 0.5 McFarland standard (~1-2 x 10^8 CFU/mL).

- Dilute the suspension in CAMHB to achieve a final concentration of ~5 x 10^5 CFU/mL (typically a 1:150 dilution).

4. Inoculation and Incubation:

- Add 50 µL of the adjusted inoculum to each well in the test rows (columns 1-12). This brings the total volume to 100 µL and achieves the final target inoculum of ~5 x 10^5 CFU/mL, with drug concentrations now at their intended 1x level.

- Seal the tray with a sterile lid or adhesive film. Incubate aerobically at 35±2°C for 16-20 hours.

5. Reading and Interpretation:

- After incubation, examine the wells visually or with a reading mirror. The MIC is the lowest concentration of the novel compound that completely inhibits visible growth.

- Compare the growth in the growth control (well 12) and sterility control (broth only) to ensure valid conditions. QC results for standard antibiotics must be within published ranges.

Title: Broth Microdilution MIC Protocol Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for CLSI-Compliant MIC Testing

| Item | Function & Critical Specification |

|---|---|

| Cation-Adjusted Mueller-Hinton Broth (CAMHB) | Standardized growth medium with controlled divalent cation (Ca2+, Mg2+) levels, ensuring consistent activity of cationic antimicrobials. |

| Sterile 96-Well U-Bottom Microdilution Trays | Non-binding, inert plastic trays for holding test volumes; U-bottom facilitates reading of bacterial pellets. |

| Automated Liquid Handler / Multichannel Pipette | Essential for accurate, high-throughput dispensing and serial dilution to minimize human error. |

| Densitometer (McFarland Standard) | Provides precise optical standardization of bacterial inoculum density for reproducible inoculum size. |

| Quality Control Strains (e.g., ATCC) | Frozen or lyophilized stocks of reference organisms with well-characterized MICs to validate each test run. |

| Sterile Dimethyl Sulfoxide (DMSO) | Primary solvent for water-insoluble novel compounds; must be at lowest possible final concentration (typically ≤1% v/v) to avoid toxicity. |

Advanced Considerations: Signaling Pathways & Resistance Mechanisms