INT Colorimetric Assay for MIC Determination: A Comprehensive Guide from Principle to Precision

This article provides a thorough exploration of the p-iodonitrophenyltetrazolium violet (INT) colorimetric assay for determining the Minimum Inhibitory Concentration (MIC) of antimicrobial agents.

INT Colorimetric Assay for MIC Determination: A Comprehensive Guide from Principle to Precision

Abstract

This article provides a thorough exploration of the p-iodonitrophenyltetrazolium violet (INT) colorimetric assay for determining the Minimum Inhibitory Concentration (MIC) of antimicrobial agents. Tailored for researchers, scientists, and drug development professionals, it covers the foundational principles of the assay, including its mechanism where INT is reduced by metabolically active bacterial cells to a colored formazan product, enabling visual or spectrophotometric MIC reading. The scope extends to detailed methodological protocols for essential oils and antibiotics, strategies for troubleshooting common sources of variability like analyst technique and reagent stability, and rigorous validation procedures against reference methods such as Etest. By synthesizing these four core intents, this guide serves as a definitive resource for implementing a robust, accurate, and reproducible INT colorimetric MIC assay in both research and development settings.

Understanding the INT Colorimetric Assay: Principles, Mechanisms, and Advantages over Traditional MIC Methods

The 2-(4-Iodophenyl)-3-(4-nitrophenyl)-5-phenyltetrazolium chloride (INT) is a tetrazolium salt that serves as a critical colorimetric viability indicator in microbiological assays. Its core principle of operation is based on its reduction by metabolically active bacterial cells into an intensely colored, insoluble formazan product. In the presence of active dehydrogenase enzyme systems within viable bacteria, the colorless, water-soluble INT is reduced to iodonitrotetrazolium formazan, which is characterized by its reddish-purple or pink color [1]. This color change provides a clear, visual endpoint for determining bacterial growth and, by extension, the efficacy of antimicrobial compounds. The INT assay is particularly valuable in Minimum Inhibitory Concentration (MIC) determination, a fundamental test in antimicrobial susceptibility testing. It offers a solution to the challenges of visual turbidity reading, which can lead to underestimation of bacterial growth, by providing a more objective, color-based signal that is directly proportional to the quantity of viable cells [1].

Application Note: INT in MIC Determination

Core Principle and Mechanism

The INT assay functions as a biochemical marker for cellular respiration. Metabolically active bacteria possess an intact electron transport chain. INT acts as an artificial electron acceptor in this chain. When bacterial cells are viable, their dehydrogenase enzymes reduce the INT molecule, cleaving the tetrazolium ring. This biochemical reduction reaction transforms the colorless INT into a vividly colored, water-insoluble formazan precipitate [1]. The intensity of the color developed is directly correlated with the number of metabolically active cells in the test system. In the context of MIC determination, a lack of color change after incubation indicates that bacterial growth has been successfully inhibited by the antimicrobial agent at that specific concentration.

Comparison with Other Viability Indicators

INT is one of several tetrazolium salts used for viability indication. Research has compared its performance against other common indicators, noting that different salts have varying properties, including toxicity and the nature of the formazan product [1]. The following table summarizes key tetrazolium salts and their characteristics:

Table 1: Comparison of Tetrazolium Salts Used as Viability Indicators

| Tetrazolium Salt | Full Name | Reduced Product (Formazan) Color | Key Characteristics |

|---|---|---|---|

| INT | 2-(4-Iodophenyl)-3-(4-nitrophenyl)-5-phenyltetrazolium chloride | Reddish-Purple / Pink | Mentioned as a common choice; properties compared in validation studies [1]. |

| TTC | 2,3,5-Triphenyltetrazolium Chloride | Red | Selected in a validated method for lower toxicity compared to INT and MTT; colorless when solubilized in water [1]. |

| MTT | 3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide | Purple | Noted to exhibit higher toxicity in comparative studies [1]. |

| XTT | 2,3-bis(2-Methoxy-4-nitro-5-sulfophenyl)-2H-tetrazolium-5-carboxanilide | Orange | Undergoes color alteration upon reduction [1]. |

| Resazurin | 7-Hydroxy-3H-phenoxazin-3-one-10-oxide | Blue (Oxidized) to Pink (Resorufin) | Used in Resazurin Microtiter Assay (REMA); color change indicates bacterial growth [2]. |

Experimental Protocol: MIC Determination Using the INT Assay

This protocol describes a standardized broth microdilution method for determining the Minimum Inhibitory Concentration of antimicrobial compounds against aerobic bacteria, using INT as a visual growth indicator.

Research Reagent Solutions and Essential Materials

Table 2: Key Reagents and Materials for INT-based MIC Assay

| Item | Function / Description |

|---|---|

| Cation-Adjusted Mueller-Hinton Broth (CAMHB) | Standardized broth medium for susceptibility testing of non-fastidious aerobic bacteria [3] [4]. |

| INT Solution | 2-(4-Iodophenyl)-3-(4-nitrophenyl)-5-phenyltetrazolium chloride, prepared at 0.2% (w/v) in sterile water. Filter-sterilize and store protected from light [1]. |

| Microdilution Panels | Sterile 96-well U-bottom plates. |

| Standardized Bacterial Inoculum | Bacterial suspension adjusted to a turbidity equivalent to a 0.5 McFarland standard, then diluted to yield a final concentration of ~5 x 10^5 CFU/mL in each well [3] [4]. |

| Antimicrobial Stock Solutions | Solutions of the test antimicrobial agent at a known, high concentration (e.g., 1280 µg/mL) for serial dilution. |

| Multichannel Pipettes | For accurate and efficient reagent distribution. |

| Microplate Incubator | Capable of maintaining 35 ± 2 °C for aerobic incubation [3]. |

| Dey-Engley (D/E) Neutralizing Broth | Contains neutralizers to inactivate residual disinfectant or antiseptic in the sample for accurate MIC determination [2]. |

Step-by-Step Procedure

Step 1: Preparation of Antimicrobial Serial Dilutions 1.1. Dispense 100 µL of CAMHB into all wells of the 96-well microdilution panel, except for the first well in each row. 1.2. In the first well, add 200 µL of the antimicrobial stock solution. 1.3. Perform a two-fold serial dilution using a multichannel pipette. Transfer 100 µL from the first well to the second, mix thoroughly, and continue this process to the penultimate well. Discard 100 µL from the penultimate well. The final well serves as the growth control (no antimicrobial) [3] [1].

Step 2: Inoculation of the Test Panel 2.1. Prepare a standardized bacterial inoculum as described in Section 3.1. 2.2. Add 10 µL of the standardized inoculum to all test wells, resulting in a final volume of 110 µL and a target inoculum of ~5 x 10^5 CFU/mL per well [1]. 2.3. Include a sterility control well (broth only) to confirm medium sterility.

Step 3: Incubation 3.1. Cover the microdilution panel and incubate at 35 ± 2 °C for 16-20 hours under aerobic conditions [3].

Step 4: Addition of INT Indicator and Final Incubation 4.1. After the initial incubation, add 20 µL of the 0.2% INT solution to each well. 4.2. Re-incubate the plate for 1-4 hours, or until a distinct color development is observed in the growth control well [1].

Step 5: Reading and Interpretation of Results 5.1. Examine the plate for a color change from colorless to reddish-purple.

- Viable Bacteria (Positive Result): Reddish-purple formazan precipitate indicates bacterial growth.

- Non-Viable Bacteria (Negative Result): No color change indicates inhibition of growth. 5.2. The Minimum Inhibitory Concentration (MIC) is defined as the lowest concentration of the antimicrobial agent that completely prevents a color change, indicating no visible bacterial growth [1].

Experimental Workflow Visualization

The following diagram illustrates the logical workflow for the INT-based MIC determination protocol:

Data Presentation and Analysis

Quantitative Data from INT-Based MIC Assays

The data generated from an INT-based MIC assay can be systematically recorded for analysis. The table below provides a hypothetical example of results for a single bacterial isolate tested against an antimicrobial agent.

Table 3: Example MIC Test Results and Interpretation Using INT

| Well Number | Antimicrobial Concentration (µg/mL) | Visual Turbidity | INT Color Reaction | Interpretation |

|---|---|---|---|---|

| 1 (Growth Control) | 0 | Turbid | Reddish-Purple | Growth |

| 2 | 1 | Clear | No Color Change | No Growth |

| 3 | 2 | Clear | No Color Change | No Growth |

| 4 | 4 | Clear | No Color Change | No Growth |

| 5 | 8 | Clear | No Color Change | No Growth |

| 6 | 16 | Slightly Turbid | Faint Pink | Partial Inhibition |

| 7 | 32 | Turbid | Reddish-Purple | Growth |

| 8 | 64 | Turbid | Reddish-Purple | Growth |

| MIC Result | 8 µg/mL |

Advanced Quantitative Applications

Beyond the qualitative MIC endpoint, the INT assay can be adapted for more advanced quantitative analysis. The formazan product can be dissolved in an organic solvent (e.g., DMSO or ethanol), and its absorbance can be measured spectrophotometrically. This absorbance value can be correlated with the number of viable cells (CFU/mL), allowing for the determination of inhibitory concentrations that cause a 50% or 90% reduction in viability (IC50% and IC90%), providing a more precise measure of an antimicrobial agent's potency [1].

Within antimicrobial drug discovery, the minimum inhibitory concentration (MIC) serves as a fundamental quantitative measure, defining the lowest concentration of an antimicrobial agent that prevents visible growth of a microorganism [5] [6]. Accurate and rapid MIC determination is critical for evaluating the efficacy of new compounds and for guiding clinical treatment strategies in the face of rising antimicrobial resistance [1] [6]. Colorimetric assays using tetrazolium salts, such as INT (2-(4-Iodophenyl)-3-(4-nitrophenyl)-5-phenyltetrazolium Chloride), have emerged as powerful tools to streamline this process. These assays leverage a vivid color change—from violet tetrazolium to red formazan—as a metabolic indicator of viable cells, enabling clearer and more objective endpoint determination than traditional turbidity measurements [1]. This application note details the biochemical mechanism of this reaction and provides a standardized protocol for employing the INT assay in MIC determination, a methodology highly relevant for research framed within the context of antibiotic susceptibility testing.

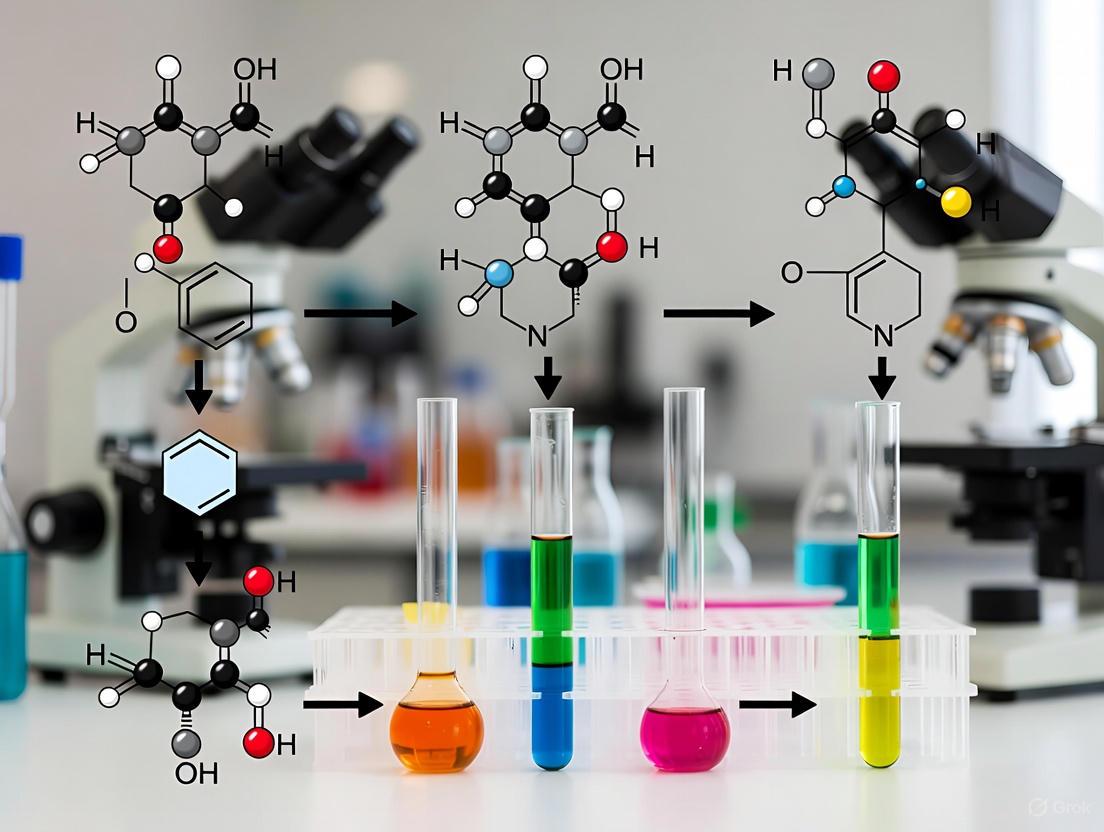

Biochemical Mechanism of Tetrazolium Reduction

The core principle of the INT colorimetric assay rests on the enzymatic reduction of a tetrazolium salt into a corresponding formazan product. The distinct violet color of the INT tetrazolium compound is transformed into a red-colored, water-insoluble formazan crystal in the presence of metabolically active microbial cells [1].

The Reduction Reaction

This color change is a visual manifestation of cellular metabolic activity. Viable microorganisms with active electron transport chains possess dehydrogenase enzymes. These enzymes, often acting in concert with the cofactor NADH, transfer electrons from metabolic substrates to the tetrazolium compound [7] [8]. The INT molecule acts as an artificial electron acceptor, becoming reduced in the process. This reduction disrupts the tetrazole ring structure, leading to the formation of the formazan dye [7]. The amount of formazan produced is directly proportional to the number of viable, metabolically active cells present [9].

Diagram 1: The biochemical pathway of INT reduction to formazan.

Application in Susceptibility Testing

In the context of antimicrobial susceptibility testing, this mechanism is harnessed to determine the MIC. When a microorganism is exposed to an effective antibiotic, its metabolic activity is inhibited or the cell is killed. Consequently, the electron transport chain is disrupted, and the reduction of INT to formazan ceases or is significantly diminished [8]. In a microdilution plate containing serial dilutions of an antibiotic, wells with concentrations below the MIC will show metabolic activity and turn red, while wells at or above the MIC will remain violet, indicating no bacterial growth [1]. This provides a clear, color-based visual endpoint for determining the MIC.

Research Reagent Solutions

The following table details the essential reagents and materials required to perform the INT colorimetric MIC assay.

Table 1: Key research reagents and their functions in the INT assay.

| Reagent/Material | Function/Description | Example/Comment |

|---|---|---|

| INT Tetrazolium Salt | Colorimetric indicator; reduced to red formazan by metabolically active cells [1]. | Prepare as a 0.2 mg/mL stock solution in water; filter-sterilize [1]. |

| Cation-Adjusted Mueller Hinton Broth (CAMHB) | Standardized culture medium for antimicrobial susceptibility testing [6]. | Ensures reproducible and accurate MIC results [6]. |

| 96-Well Microtiter Plate | Platform for broth microdilution testing [1] [6]. | U-bottom plates are commonly used. |

| Antibiotic Stock Solutions | Source of the antimicrobial agent for serial dilution [6]. | Typically prepared at high concentration (e.g., 10 mg/mL) in appropriate solvent [6]. |

| Inoculum Standard | Standardized microbial suspension for inoculation [1] [6]. | Adjusted to 0.5 McFarland standard (~1-2 x 10⁸ CFU/mL for bacteria). |

Detailed Experimental Protocol for MIC Determination

This protocol is adapted from standardized methods for broth microdilution and colorimetric assessment [1] [6] [10].

Pre-Assay Preparation

- INT Solution Preparation: Dissolve INT powder in sterile distilled water to a concentration of 0.2 mg/mL. Filter-sterilize the solution using a 0.2 µm membrane filter. The solution can be stored protected from light at 4°C [1].

- Antibiotic Serial Dilution:

- Prepare a stock solution of the test antibiotic. Common solvents include water, methanol, or DMSO, chosen based on the compound's solubility [6].

- Perform two-fold serial dilutions of the antibiotic in CAMHB across the wells of a 96-well microtiter plate. A typical volume is 100 µL per well. The concentration range should encompass the expected MIC and clinical breakpoints [6].

- Inoculum Preparation:

- Grow the test microorganism on an appropriate solid medium for 18-24 hours.

- Suspend colonies in a sterile saline solution and adjust the turbidity to match a 0.5 McFarland standard (approximately 1-2 x 10⁸ CFU/mL for bacteria) [1] [6].

- Further dilute this suspension in CAMHB to achieve a final working inoculum, which is typically around 5 x 10⁵ CFU/mL.

Assay Procedure and Incubation

- Inoculation: Add 100 µL of the prepared working inoculum to each well of the microtiter plate containing the antibiotic dilutions. This step brings the final test volume to 200 µL per well and the final bacterial concentration to approximately 5 x 10⁵ CFU/mL.

- Controls:

- Growth Control: Include a well containing 100 µL of CAMHB and 100 µL of inoculum (no antibiotic).

- Sterility Control: Include a well containing 200 µL of CAMHB only (no inoculum, no antibiotic).

- Incubation: Seal the microtiter plate and incubate at 35±2°C for 16-20 hours, unless testing slow-growing organisms [6].

Colorimetric Development and MIC Reading

- INT Addition: After the initial incubation period, add 20-30 µL of the 0.2 mg/mL INT solution to each well [1].

- Secondary Incubation: Re-incubate the plate for 1-4 hours at 35±2°C. Monitor the plate periodically for color development.

- Endpoint Determination: The MIC is defined as the lowest concentration of antibiotic that completely prevents a color change to red. Wells with viable, growing bacteria will turn pink/red due to formazan production, while wells with inhibited growth will remain colorless (or the color of the original medium) [1].

Diagram 2: Experimental workflow for the INT microdilution assay.

Data Interpretation and Quantitative Analysis

The INT assay provides qualitative and quantitative data for determining antimicrobial activity.

Visual and Spectrophotometric Reading

The primary readout is visual: a clear well indicates no growth (inhibited), and a red well indicates growth. For a more objective and quantitative analysis, the optical density (OD) of each well can be measured using a microplate reader. Formazan production can be quantified at 570 nm, and the absorbance values are correlated with the number of viable cells [1]. This allows for the calculation of IC50% and IC90% (the concentrations inhibiting 50% and 90% of growth, respectively) in addition to the standard MIC [1].

Table 2: Example of MIC results and interpretation for a hypothetical antibiotic against S. aureus.

| Antibiotic Concentration (µg/mL) | Visual Color | OD570 nm | Growth Interpretation | MIC Determination |

|---|---|---|---|---|

| 16 | Colorless | 0.05 | No Growth | |

| 8 | Colorless | 0.06 | No Growth | MIC = 4 µg/mL |

| 4 | Faint Pink | 0.25 | Inhibited Growth | |

| 2 | Red | 0.85 | Growth | |

| 1 | Red | 0.89 | Growth | |

| 0.5 | Red | 0.91 | Growth | |

| Growth Control | Red | 0.90 | Growth | |

| Sterility Control | Colorless | 0.04 | No Growth |

Validation and Comparison with Reference Methods

The performance of the INT assay should be validated against reference strains with known MIC values. Studies on similar tetrazolium and colorimetric assays have shown excellent correlation with standard broth microdilution and molecular methods (e.g., mecA gene detection for MRSA), with category agreement often exceeding 99% [9] [10]. A key advantage of the INT method is its speed, providing results in 5-7 hours post-inoculation for many fast-growing bacteria, compared to the 16-20 hours required for a standard visual MIC readout [9] [10].

The colorimetric assay for Minimum Inhibitory Concentration (MIC) determination represents a significant advancement in antimicrobial susceptibility testing (AST). By utilizing redox indicators like INT (Iodonitrotetrazolium chloride) or colorimetric pH sensors, these assays transform the visual interpretation of bacterial growth and metabolic activity into a simple color change output [11] [12]. This document details the application and protocol for INT colorimetric assays, highlighting their key advantages—simplicity, accuracy, and reproducibility—within modern research and drug development pipelines. The integration of such methods addresses the growing need for rapid, reliable diagnostics in the face of increasing antimicrobial resistance [11].

Key Advantages and Quantitative Performance

The INT colorimetric assay offers a compelling alternative to traditional AST methods like broth microdilution. Its performance is characterized by the following advantages:

- Simplicity: The assay requires minimal specialized equipment compared to reference methods. The color change endpoint is visually interpretable, facilitating use in various settings [11].

- Accuracy: The method demonstrates high categorical agreement with reference standards. For instance, similar colorimetric principles have shown sensitivity and specificity values exceeding 95% in related diagnostic applications [12].

- Reproducibility: The use of stable chemical indicators and standardized protocols ensures consistent results across different operators and laboratories [13].

Table 1: Comparative Analysis of AST Methods

| Method Feature | INT Colorimetric Assay | Reference Broth Microdilution [11] | Disk Diffusion [11] |

|---|---|---|---|

| Turnaround Time | 2 - 6 hours (with rapid metabolic indicator) | 18 - 24 hours | 18 - 24 hours |

| Result Output | Quantitative (MIC) | Quantitative (MIC) | Qualitative/Semi-quantitative (S/I/R) |

| Equipment Cost | Low (spectrophotometer optional) | Moderate (requires dedicated trays, reader) | Low |

| Ease of Automation | High (suitable for microtiter plates) | High | Low |

| Per-test Cost | Low | Moderate to High | Low ($2 - $5) |

Table 2: Performance Metrics of Colorimetric Assays in Related Applications

| Assay Type | Target | Reported Sensitivity | Reported Specificity | Linear Range / LOD |

|---|---|---|---|---|

| ColorPhAST [12] | Phage susceptibility in E. coli | 95.6% | 100% | N/A |

| GSH Detection [14] | Glutathione | N/A | N/A | 0–152.7 μM (LOD: 0.74 μM) |

| Tyrosinase Assay [15] | Tyrosinase | N/A | N/A | LOD: 4.13 x 10⁻⁵ U/mL |

Experimental Protocol: INT Colorimetric MIC Determination

This protocol is adapted for a 96-well microtiter plate format, enabling high-throughput screening of compounds against bacterial pathogens.

Materials and Reagents

Table 3: Research Reagent Solutions

| Item | Function/Description |

|---|---|

| Cation-adjusted Mueller Hinton Broth (CAMHB) | Standardized growth medium for AST as per EUCAST/CLSI guidelines [4]. |

| INT (Iodonitrotetrazolium chloride) Solution | Redox indicator. Prepared as a 2 mg/mL stock solution in sterile water and filter-sterilized. |

| Test Compound/Antibiotic | Serial dilutions prepared in CAMHB. |

| Bacterial Inoculum | Adjusted to a 0.5 McFarland standard, then diluted to ~1-5 x 10⁵ CFU/mL in CAMHB. |

| Sterile 96-Well Microtiter Plates | Platform for broth microdilution assay. |

| Multichannel Pipettes | For efficient reagent and inoculum dispensing. |

| Microplate Spectrophotometer (Optional) | For objective measurement of absorbance at 490-520 nm. |

Procedure

Day 1: Preparation

- Compound Dilution Series: In a sterile 96-well plate, perform a two-fold serial dilution of the antibiotic or test compound in CAMHB across the rows (e.g., 100 μL/well). Leave the last column without antibiotic for growth control wells.

- Inoculum Preparation: Pick 3-5 colonies from an overnight agar plate and suspend in sterile saline. Adjust the turbidity to a 0.5 McFarland standard (approx. 1-2 x 10⁸ CFU/mL). Dilute this suspension 1:100 in CAMHB to achieve a working inoculum of ~1-5 x 10⁶ CFU/mL.

Day 1: Inoculation and Incubation

- Plate Inoculation: Add 100 μL of the bacterial inoculum to all test and growth control wells. Add 100 μL of sterile CAMHB to the sterility control wells.

- Incubation: Seal the plate with a lid or parafilm and incubate at 35±2°C for 16-20 hours under normal atmospheric conditions.

Day 2: INT Staining and MIC Reading

- INT Addition: After incubation, add 20-40 μL of the sterile INT stock solution (2 mg/mL) to each well.

- Re-incubation: Re-incubate the plate for 30 minutes to 4 hours. Monitor periodically for color development.

- Endpoint Determination:

- Visual: The MIC is defined as the lowest concentration of the antibiotic that prevents a color change to pink/red. A color change indicates bacterial metabolic activity and reduction of INT to formazan.

- Spectrophotometric: Read the absorbance at 490-520 nm. The MIC is the lowest concentration where the absorbance is statistically indistinguishable from the sterility control.

Signaling Principle and Workflow Visualization

The INT assay is based on a straightforward biochemical principle. Metabolically active bacterial cells reduce the tetrazolium compound INT, which is colorless or yellow, into an intracellular, colored formazan product (pink/red). Inhibition of bacterial growth by an effective antibiotic prevents this reduction, thus inhibiting the color change [11].

Diagram 1: INT Colorimetric Signaling Principle.

The experimental workflow, from plate preparation to data analysis, is streamlined for efficiency and reliability, as outlined below.

Diagram 2: INT MIC Assay Workflow.

This application note provides a detailed comparative analysis of the p-iodonitrotetrazolium chloride (INT) colorimetric assay against the established agar dilution and broth macrodilution methods for determining the Minimum Inhibitory Concentration (MIC) of antimicrobial agents. MIC is defined as the lowest concentration of an antimicrobial agent that completely inhibits visible growth of a microorganism under controlled conditions [16]. We present standardized protocols, comparative performance data, and practical considerations to assist researchers in selecting the appropriate methodology for their antimicrobial susceptibility testing requirements. The INT colorimetric assay offers a rapid, sensitive alternative to traditional methods, particularly valuable in high-throughput screening environments and when evaluating colored substances that complicate visual interpretation.

Determining the Minimum Inhibitory Concentration (MIC) is a fundamental practice in microbiology for assessing the efficacy of antimicrobial compounds. While dilution methods are considered the gold standard, colorimetric assays have emerged as efficient alternatives addressing specific limitations of traditional approaches.

Agar dilution involves incorporating the antimicrobial agent into molten agar medium, pouring plates with serial concentrations, and spotting standardized inocula onto the agar surface. The MIC is the lowest concentration preventing visible growth after incubation [17] [18] [19]. It is regarded as a reference method with excellent reproducibility and is cost-effective for testing numerous bacterial isolates against a limited set of antimicrobial agents [17] [19].

Broth macrodilution employs a series of test tubes containing broth with two-fold serial dilutions of the antimicrobial agent. After inoculation with a standardized microbial suspension and incubation, the MIC is determined as the tube with the lowest concentration showing no visible turbidity [16] [20]. This method, while foundational, is resource-intensive and less suited for high-throughput applications.

The INT colorimetric assay utilizes the metabolic indicator p-iodonitrotetrazolium chloride, which is reduced by metabolically active bacteria from a colorless compound to a pink-red formazan derivative. The MIC is identified as the lowest concentration of antimicrobial agent where no color change occurs, indicating complete inhibition of microbial metabolism [21]. This method is particularly advantageous for its objectivity and rapid readout.

Comparative Methodologies: Protocols and Procedures

Agar Dilution Protocol

The agar dilution method is a robust, standardized technique recommended for testing large batches of bacterial isolates [17] [19].

Materials:

- Mueller-Hinton Agar (MHA) or appropriate supplemented medium (e.g., MHA with 5% sheep blood for fastidious organisms)

- Antimicrobial stock solution

- Bacterial strains adjusted to 0.5 McFarland standard (~1 x 10⁸ CFU/mL)

- Replicator device delivering 1-5 μL (final inoculum ~5 x 10⁴ CFU/spot)

Procedure:

- Prepare a series of two-fold dilutions of the antimicrobial agent in sterile water or an appropriate solvent [16].

- Incorporate each dilution into separate batches of molten agar, mixing thoroughly.

- Pour the antimicrobial-supplemented agar into Petri dishes and allow to solidify.

- Apply the standardized bacterial inocula (30-36 spots per plate) using a replicator device.

- Incubate the plates under optimal conditions (e.g., 35°C for 16-20 hours in ambient air or CO₂ for fastidious bacteria).

- Read the MIC as the lowest antimicrobial concentration that completely inhibits visible growth [18] [19].

Broth Macrodilution Protocol

This method determines MIC in a liquid medium system, often performed in tubes [20].

Materials:

- Mueller-Hinton Broth (MHB) or appropriate supplemented medium

- Antimicrobial stock solution

- Test tubes

- Bacterial suspension adjusted to 0.5 McFarland standard, further diluted to yield ~5 x 10⁵ CFU/mL in the final test volume

Procedure:

- Prepare a series of two-fold dilutions of the antimicrobial agent in MHB within test tubes.

- Inoculate each tube with the standardized bacterial suspension.

- Incubate the tubes under optimal conditions (e.g., 35°C for 16-20 hours).

- Read the MIC as the lowest antimicrobial concentration that completely inhibits visible turbidity [16] [20].

INT Colorimetric Assay Protocol

The INT assay provides a metabolic endpoint for growth inhibition, enhancing objectivity [21].

Materials:

- Mueller-Hinton Broth (MHB)

- 96-well microtiter plates

- Antimicrobial stock solution and/or plant extracts

- Bacterial suspension adjusted to ~10⁶ CFU/mL in MHB

- INT solution (0.2 mg/mL of p-iodonitrotetrazolium chloride, filter-sterilized)

Procedure:

- Serially dilute the antimicrobial agent or plant extract two-fold in MHB within the wells of a 96-well microtiter plate.

- Inoculate each well with the standardized bacterial suspension.

- Incubate the plate at 37°C for 20 hours.

- Add INT solution (e.g., 40 μL per well) and incubate for an additional 30 minutes.

- Read the MIC as the lowest concentration of the antimicrobial agent in a well that remains clear (no pink-red color formation) after the addition and incubation with INT [21].

Comparative Performance Data

The following tables summarize key characteristics and performance metrics of the three MIC determination methods.

Table 1: Method Characteristics and Operational Comparison

| Parameter | INT Colorimetric Assay [21] | Agar Dilution [17] [19] | Broth Macrodilution [16] [20] |

|---|---|---|---|

| Principle | Metabolic activity (color change) | Visible growth on solid medium | Visible growth (turbidity) in liquid medium |

| Throughput | High (96-well format) | High for isolates, low for agents | Low |

| Subjectivity | Low (colorimetric endpoint) | Moderate (visual growth) | Moderate (visual turbidity) |

| Turnaround Time | ~20.5 hours | 16-48 hours | 16-20 hours |

| Cost per Test | Low | Cost-effective for batch testing | High (resource-intensive) |

| Ease of Automation | High | Low | Low |

Table 2: Reported Method Agreement in Literature

| Comparison | Agreement | Context / Organisms | Source |

|---|---|---|---|

| Broth Microdilution vs. Etest | 88% within ±1 log₂ dilution | Doripenem vs. Gram-positive and Gram-negative bacteria | [22] |

| Broth Microdilution vs. Agar Dilution | 94% within ±1 log₂ dilution | Doripenem vs. Gram-positive and Gram-negative bacteria | [22] |

| Broth Microdilution vs. Agar Dilution | 78.7% within 1 log₂ MIC | Campylobacter jejuni and C. coli | [23] |

| REMA vs. D/E Neutralizer (Colorimetric) | 90.3% overall agreement | Povidone-Iodine vs. S. aureus and K. aerogenes | [2] |

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagent Solutions for MIC Determination

| Reagent | Function & Application | Key Considerations |

|---|---|---|

| p-Iodonitrotetrazolium Chloride (INT) | Colorimetric indicator of cellular metabolic activity. Used in the INT assay, it is reduced from colorless to pink-red formazan in the presence of growing bacteria [21]. | Filter sterilize. Optimize concentration and incubation time to prevent background color development. |

| Mueller-Hinton Agar/Broth | Standardized, nutritionally adequate medium for antimicrobial susceptibility testing of non-fastidious bacteria [19] [16]. | For fastidious organisms, supplementation (e.g., 5% sheep blood) is required as per CLSI/EUCAST guidelines. |

| Dey-Engley (D/E) Neutralizing Broth | Contains neutralizing agents (e.g., Tween, lecithin) to inactivate disinfectants and antimicrobials during testing, preventing carry-over effect. Can include a colorimetric indicator [2]. | Critical for evaluating antiseptics and disinfectants to ensure accurate MIC results. |

| Resazurin Sodium Salt | Oxidation-reduction indicator used in assays like REMA. It changes from blue to pink/colorless upon reduction by metabolically active cells [2]. | Can be more sensitive than INT but may require fluorescence measurement for optimal detection. |

| Dimethyl Sulfoxide (DMSO) | Common solvent for dissolving hydrophobic antimicrobial compounds, plant extracts, or synthetic drugs prior to dilution in aqueous media [16]. | Use the lowest possible concentration as high levels can be toxic to test microorganisms. |

The selection of an MIC method depends on the specific research objectives, sample type, and available resources.

For high-throughput screening of novel compounds or plant extracts, the INT colorimetric assay in a 96-well microplate format is highly recommended. Its objective endpoint, speed, and minimal reagent requirements make it ideal for processing large numbers of samples [21]. It is particularly useful for testing colored plant extracts that can obscure visual growth reading in traditional methods.

For reference testing and batch analysis of multiple bacterial isolates against a few agents, agar dilution remains the gold standard. Its high reproducibility and capacity to test up to 30 isolates simultaneously per plate make it cost-effective for surveillance studies [17] [19].

Broth macrodilution, while foundational, is now primarily used when other methods are not feasible or for specific organism-drug combinations. Its labor-intensive and resource-heavy nature limits its use in modern high-volume laboratories [20].

In conclusion, while agar dilution provides a benchmark for accuracy, the INT colorimetric assay offers a reliable, rapid, and efficient alternative for quantitative MIC determination, especially within the context of drug discovery and resistance monitoring. Researchers should validate any non-reference method against a standard dilution method for their specific microbial strains to ensure result reliability.

The rising threat of antimicrobial resistance necessitates the continuous discovery and evaluation of new antimicrobial agents, including natural products like essential oils (EOs) and novel synthetic antibiotics [24]. Fastidious organisms, with their complex nutritional requirements and slow growth rates, present a significant challenge for conventional antimicrobial susceptibility testing (AST) [25] [26]. The INT colorimetric assay for minimum inhibitory concentration (MIC) determination offers a robust, sensitive, and quantitative solution for screening compounds against these demanding microorganisms. This application note details standardized protocols integrating this colorimetric method, framed within broader research on optimizing MIC determinations for fastidious bacteria.

The Challenge of Fastidious Organisms and Essential Oils in Susceptibility Testing

Fastidious bacteria, such as the HACEK group (Haemophilus, Aggregatibacter, Cardiobacterium, Eikenella, Kingella), Abiotrophia, Granulicatella, and Campylobacter spp., require specialized media, atmospheric conditions, and often extended incubation times for growth [25] [26]. The lack of standardized testing guidelines for many of these organisms further complicates the reliable assessment of their susceptibility [25].

Similarly, evaluating the antimicrobial properties of EOs is problematic due to their complex, hydrophobic, and volatile nature [27]. Conventional broth microdilution methods can be affected by the insolubility of EOs in aqueous media and the potential for vapor-phase activity, which may lead to cross-contamination between wells in a microtiter plate [27]. The INT colorimetric assay addresses key limitations of visual turbidity readings by providing a clear, objective color change linked to microbial metabolic activity, thereby enhancing the accuracy and reliability of MIC endpoints for both fastidious organisms and complex natural products [1].

The INT Colorimetric Assay: Principle and Advantages

The INT (2-(4-Iodophenyl)-3-(4-nitrophenyl)-5-phenyltetrazolium chloride) assay is a colorimetric method used to determine cell viability and metabolic activity. Metabolically active bacteria reduce the colorless, water-soluble INT salt to a red-colored, water-insoluble formazan product [1]. The intensity of the red color is directly proportional to the number of viable cells.

Advantages of the INT assay include:

- Objectivity: Provides a clear, color-based endpoint, reducing the subjectivity associated with visual turbidity assessment [1].

- Sensitivity: Can detect low levels of microbial growth that are not visible to the naked eye [1].

- Quantification: The signal can be measured spectrophotometrically to determine inhibitory concentrations such as IC50% and IC90%, providing data on the potency of antimicrobial compounds [1].

The diagram below illustrates the signaling pathway and workflow for the INT colorimetric MIC assay.

Research Reagent Solutions for Fastidious Organism Testing

The table below outlines essential materials and their specific functions for conducting INT colorimetric MIC assays on fastidious organisms.

Table 1: Essential Research Reagents and Materials

| Item | Function & Application | Key Considerations |

|---|---|---|

| MH-F Broth | Enriched Mueller-Hinton broth for fastidious organisms [4]. Supports growth of streptococci, H. influenzae, etc. | Must be supplemented with lysed horse blood and beta-NAD [4]. |

| INT Solution | Cell viability indicator. Colorless INT is reduced to red formazan by metabolically active bacteria [1]. | Final concentration typically 0.02-0.2 mg/mL. Filter-sterilized before use. |

| Dimethyl Sulfoxide (DMSO) / Polysorbate 80 | Solvent/emulsifier for hydrophobic compounds like essential oils [27]. | Final solvent concentration must be non-inhibitory to bacterial growth (typically ≤1-2% v/v) [27]. |

| Cation-Adjusted Mueller-Hinton Broth (CAMHB) | Standard broth for non-fastidious aerobic bacteria [28] [26]. Used for quality control strains. | Essential for reliable testing of antibiotics like polymyxins [28]. |

| Quality Control Strains | Verifies accuracy and precision of the AST procedure [28] [26]. | Examples: E. coli ATCC 25922, S. aureus ATCC 29213. Must be organism- and antibiotic-specific [28]. |

Quantitative MIC Data for Essential Oils and Antibiotics

The following tables summarize published MIC values for various essential oils and standard antibiotics, providing reference points for assay validation and result interpretation.

Table 2: MIC Values of Selected Essential Oils Against Reference Bacteria

| Plant Source (Essential Oil) | Microorganism | MIC Value | Reference |

|---|---|---|---|

| Cymbopogan citratus (Lemongrass) | Escherichia coli | 0.6 µL/mL | [24] |

| Staphylococcus aureus | 0.6 µL/mL | [24] | |

| Salmonella typhimurium | 2.5 µL/mL | [24] | |

| Thymus vulgaris (Thyme) | Clostridium perfringens | 1.25 mg/mL | [24] |

| Origanum vulgarae (Oregano) | Escherichia coli | 1600–1800 ppm | [24] |

| Staphylococcus aureus | 800–900 ppm | [24] | |

| Cinnamomum zeylanicum (Cinnamon) | Staphylococcus aureus | 0.5 mg/mL | [24] |

| Allium sativum (Garlic) | Escherichia coli | 15–1500 µg/mL | [24] |

Table 3: Example Clinical Breakpoints for Antibiotics (EUCAST)

| Antibiotic | Organism | Susceptible (S) MIC Breakpoint (≤ mg/L) | Resistant (R) MIC Breakpoint (> mg/L) | Reference |

|---|---|---|---|---|

| Ceftazidime | Escherichia coli | 1 mg/L | 4 mg/L | [28] |

| Benzylpenicillin | Streptococcus pneumoniae | 0.06 mg/L | 2 mg/L | [4] |

| Clarithromycin | Helicobacter pylori | 0.25 mg/L | 0.5 mg/L | [25] |

Detailed Experimental Protocols

Protocol 1: Broth Microdilution MIC Assay with INT Endpoint for Fastidious Organisms

This protocol is adapted from EUCAST guidelines and validated colorimetric methods [28] [1] [4].

Day 1: Preparation of Inoculum

- Using a sterile loop, streak the fastidious organism from a frozen stock onto an appropriate enriched agar plate (e.g., chocolate agar). Incubate at 35±1°C in 5% CO₂ for 18-24 hours [28] [26].

- Prepare a bacterial suspension in sterile saline (0.85% NaCl) directly from overnight colonies, adjusting the turbidity to a 0.5 McFarland standard. This results in a suspension of approximately 1-2 x 10⁸ CFU/mL [28] [1].

Day 2: MIC Assay Procedure

- Prepare Antimicrobial Stock Solutions: Dissolve antibiotics in appropriate solvents (e.g., water, methanol). For Essential Oils, prepare a stock solution in a non-inhibitory concentration of DMSO or polysorbate 80 (e.g., 1% v/v) [27].

- Dilution Scheme: In a sterile 96-well microtiter plate, perform two-fold serial dilutions of the antimicrobial agent in MH-F broth [4]. Include a growth control well (MH-F broth + inoculum) and a sterility control well (MH-F broth only).

- Inoculate Plate: Dilute the 0.5 McFarland standard suspension 1:100 in MH-F broth to achieve a final inoculum of ~5 x 10⁵ CFU/mL. Add 100 µL of this standardized inoculum to all test and growth control wells. Add 100 µL of sterile MH-F broth to the sterility control well. The final volume in each test well is 200 µL.

- Incubate: Seal the microtiter plate with a lid and incub at 35±1°C for 16-20 hours under appropriate atmospheric conditions (e.g., 5% CO₂ if required) [26] [4].

- Add INT and Re-incubate: After initial incubation, add 20 µL of a filter-sterilized INT solution (0.125% w/v) to each well. Re-incubate the plate for 1-4 hours [1].

- Determine MIC Endpoint:

- Visual Reading: The MIC is the lowest concentration of the antimicrobial agent that prevents a color change to red. A pink/red color indicates bacterial growth and metabolic activity [1].

- Spectrophotometric Reading: Measure the absorbance at 490 nm using a microplate reader. The MIC is the lowest concentration that results in an optical density (OD) below a predefined threshold (e.g., 90% inhibition compared to the growth control) [1]. This allows for calculation of IC50 and IC90 values.

Protocol 2: Quality Control and Data Interpretation

- Quality Control: Each assay run must include approved quality control (QC) strains with known MIC ranges [28] [26]. Results are valid only if the MIC for the QC strain falls within the accepted reference range.

- Interpretation: For antibiotics, compare the obtained MIC value to the current clinical breakpoints published by EUCAST or CLSI to categorize the isolate as Susceptible (S), Intermediate (I), or Resistant (R) [28]. For essential oils or investigational compounds, the MIC value itself is the primary result, though it can be compared to Epidemiologic Cutoff Values (ECVs) if available [26].

The integration of the INT colorimetric assay into standardized broth microdilution provides a powerful, quantitative tool for screening the efficacy of essential oils and antibiotics against fastidious organisms. This method enhances the objectivity and sensitivity of MIC determinations, facilitating reliable data generation for antimicrobial discovery and resistance surveillance. The protocols outlined herein, utilizing specialized media like MH-F broth, offer researchers a robust framework to advance studies within the broader context of developing novel strategies to combat multidrug-resistant infections.

Step-by-Step Protocol: Developing and Executing a Robust INT Colorimetric MIC Assay

The p-Iodonitroterazolium Chloride (INT) colorimetric assay is a vital tool in microbiological research for rapidly determining the Minimum Inhibitory Concentration (MIC) of antimicrobial agents [29]. The assay functions as a bacterial viability indicator; viable bacteria reduce the yellow, water-soluble INT dye to a pink, water-insoluble formazan product, providing a clear visual or spectrophotometric endpoint for growth [29]. This method is particularly valued for its speed and simplicity compared to traditional broth dilution methods. However, the reliability of the INT assay is critically dependent on the stability of the prepared INT solution. Degradation of the reagent can lead to diminished colorimetric response, resulting in false negatives or an overestimation of antimicrobial activity. This application note details the preparation, storage, and stability testing protocols for INT solution to ensure data integrity within MIC determination research.

Key Research Reagent Solutions

The following table outlines the essential reagents and materials required for the preparation and use of the INT colorimetric assay in MIC studies.

Table 1: Essential Reagents for INT Colorimetric MIC Assays

| Reagent/Material | Function/Description | Application Notes |

|---|---|---|

| p-Iodonitroterazolium Chloride (INT) | Colorimetric viability indicator. Reduced by bacterial dehydrogenases from yellow to pink formazan [29]. | Critical to prepare at specified concentration (e.g., 0.2 µg/mL) [29]. Stability of prepared solution is a key focus of this document. |

| Dimethyl Sulfoxide (DMSO) | Common solvent for preparing stock solutions of antimicrobials or dyes like INT [29]. | Must be tested to ensure no inherent antibacterial activity at concentrations used in the assay [29]. |

| Cation-Adjusted Mueller-Hinton Broth (CAMHB) | Standardized growth medium for broth microdilution susceptibility testing [30]. | Provides essential nutrients and controlled ion concentration for reproducible bacterial growth. |

| Resazurin Dye | Alternative colorimetric viability indicator. Reduced from blue to pink [2] [30]. | Used in Resazurin Microplate Assay (REMA); serves as a comparative method for INT [2] [30]. |

| Dey-Engley (D/E) Neutralizer Broth | Growth medium containing neutralizing agents to inactivate disinfectants/antiseptics during testing [2]. | Contains bromcresol purple as a pH-based colorimetric indicator for bacterial growth [2]. |

INT Solution Preparation and Quality Control

Stock Solution Preparation Protocol

A standardized protocol is essential for consistent and reliable INT assay performance.

- Step 1: Weighing. Accurately weigh the required mass of INT powder to prepare a 0.02% (w/v) stock solution (e.g., 0.02 g in 100 mL of solvent) [30].

- Step 2: Reconstitution. Dissolve the INT powder in an appropriate sterile solvent, such as deionized water or phosphate-buffered saline (PBS). The Resazurin protocol suggests sterile filtration for sterilization [30].

- Step 3: Sterilization. Sterilize the prepared 0.02% INT stock solution by passing it through a 0.22 µm membrane filter into a sterile container [30]. This step is critical to prevent microbial contamination.

- Step 4: Aliquoting. Dispense the sterile stock solution into single-use, light-protected vials (e.g., amber vials) to minimize freeze-thaw cycles and light exposure.

Working Solution Preparation

- The stock solution is typically diluted for use in assays. The referenced protocol uses a final concentration of 0.2 µg/mL, which is achieved by adding 50 µL of the 0.02% stock to the test well [29].

Initial Quality Control Assessment

- Positive Control: Validate each new batch of INT solution by testing with a known viable bacterial strain (e.g., E. coli ATCC 25922). A distinct color change from yellow to pink within the expected incubation time confirms reagent functionality [29] [30].

- Negative Control: Include a sterility control well (broth and INT without bacteria) to confirm the reagent itself does not change color, indicating absence of contamination or auto-reduction.

Stability Storage and Testing Protocols

Recommended Storage Conditions

Based on general practices for critical laboratory reagents and stability guidelines, the following storage conditions are recommended for INT solutions.

Table 2: Recommended Storage Conditions for INT Solutions

| Solution Type | Short-Term Storage | Long-Term Storage | Container | Documentation |

|---|---|---|---|---|

| INT Working Solution | 4°C (refrigerator), protected from light for up to 24 hours. |

Not recommended. Prepare fresh from stock for each assay. | Sterile, light-protected microcentrifuge tubes. | Label with preparation date, time, and initials. |

| INT Stock Solution (0.02%) | Not recommended for extended periods. | -20°C or lower, protected from light [30]. |

Small, sterile aliquots in amber vials. | Label with reagent name, concentration, date prepared, and expiration date. |

Stability storage involves placing samples in controlled environments to determine how their quality varies with time under factors like temperature and light [31]. For a light-sensitive reagent like INT, photostability is a key concern. ICH guidelines recommend testing under exaggerated light conditions to establish appropriate handling and storage protocols [31].

Forced Degradation Study Protocol

Forced degradation studies provide knowledge about the degradation chemistry of a substance, which is used to develop stability-indicating methods [31]. This protocol helps establish the stability profile of INT solution.

- Objective: To determine the intrinsic stability of INT solution by subjecting it to stress conditions and evaluating its physical and functional integrity.

- Materials:

- Method:

- Aliquot Preparation: Dispense INT solution into multiple aliquots.

- Stress Application:

- Thermal Stress: Store aliquots at

40°Cand60°C[32]. - Photostress: Expose one aliquot to at least 1.2 million lux hours of visible light and 200-watt hours per square meter of UV energy in a light cabinet [31].

- Control: Maintain a control aliquot at the recommended long-term storage condition (

-20°C, dark).

- Thermal Stress: Store aliquots at

- Sampling and Analysis: At predetermined intervals (e.g., 24h, 72h, 1 week), retrieve aliquots for testing.

- Physical Inspection: Note any color change or precipitation.

- Functional QC: Perform the standard INT assay against the QC strain alongside a fresh INT solution control. Compare the color development time and intensity.

- Acceptance Criteria: The stressed INT solution is considered stable if it produces a functional response (color change) equivalent to the control within one doubling dilution in the MIC assay.

Real-Time Stability Study Protocol

Long-term stability testing determines the re-test period or shelf life under recommended storage conditions [31] [33].

- Objective: To establish the shelf-life of the INT stock solution by monitoring its performance over time under recommended storage conditions (

-20°C, dark). - Method:

- Study Design: Prepare multiple aliquots from a single, master batch of 0.02% INT stock solution.

- Storage: Store all aliquots at

-20°Cin the dark. - Testing Schedule: Pull aliquots at predefined time points (e.g., initial, 1, 3, 6, 9, 12 months) for functional QC testing against a standard strain.

- Data Recording: Document the physical appearance and the results of the functional QC assay at each interval.

- Defining Shelf-Life: The shelf-life is the period during which the INT solution consistently meets all acceptance criteria (physical and functional) compared to a fresh control.

Experimental Workflow for INT Stability Assessment

The following diagram illustrates the logical workflow for preparing the INT solution and conducting stability assessments to ensure its reliability in the MIC assay.

INT Solution Stability Assessment Workflow

Data Presentation and Analysis

The following table summarizes hypothetical data from a comprehensive stability study, illustrating how to document and analyze the results.

Table 3: Example Data from a Comprehensive INT Solution Stability Study

| Storage Condition | Time Point | Physical Appearance | Functional QC Result | MIC Correlation with Fresh Control | Conclusion |

|---|---|---|---|---|---|

Recommended (-20°C, dark) |

Initial | Clear, yellow | Pass | Essential Agreement: 100% | Suitable for use |

| 6 Months | Clear, yellow | Pass | Essential Agreement: 100% | Suitable for use | |

| 12 Months | Clear, yellow | Pass | Essential Agreement: 100% | Suitable for use | |

Accelerated (40°C, dark) |

2 Weeks | Slight darkening | Pass | Essential Agreement: 100% | Stable under short-term stress |

| 4 Weeks | Noticeable darkening | Fail (No color change) | Essential Agreement: 0% | Degradation evident | |

| Photostress (ICH Q1B) | 24 Hours | Faded yellow | Fail (Weak color change) | Essential Agreement: ≤50% | Highly light-sensitive |

Adherence to the detailed protocols for preparation, storage, and systematic stability testing of INT solution, as outlined in this application note, is fundamental for ensuring the generation of reliable and reproducible data in MIC determination research. Establishing a defined shelf-life through real-time studies and understanding the reagent's vulnerabilities via forced degradation minimizes experimental variability. Proper handling of this critical reagent, characterized by sterile aliquoting, light-protected storage at -20°C, and rigorous quality control, directly supports the integrity of antimicrobial efficacy studies and the broader fight against antimicrobial resistance.

Broth microdilution is the reference method for determining the Minimum Inhibitory Concentration (MIC) of antimicrobial substances, providing both quantitative and qualitative assessment of antimicrobial efficacy. The accuracy and reproducibility of this method fundamentally depend on precise inoculum preparation and standardization. This protocol details the optimized procedures for preparing a standardized bacterial inoculum specifically for broth microdilution MIC assays, with particular emphasis on integration with colorimetric endpoint detection. Adherence to this standardized methodology ensures reliable, reproducible results essential for research and drug development applications.

In antimicrobial susceptibility testing, the minimum inhibitory concentration (MIC) is defined as the lowest concentration of an antimicrobial agent that prevents visible growth of a microorganism [28]. The broth microdilution method, performed in 96-well plates, has become the gold standard for MIC determination in both clinical and research settings due to its quantitative nature, reproducibility, and capacity for high-throughput analysis [20] [28]. This method's reliability, however, is critically dependent on strict standardization of the bacterial inoculum used in the assay.

The preparation of a correct inoculum density is not merely a procedural step but a fundamental determinant of assay validity. An excessively heavy inoculum may lead to falsely elevated MIC values, suggesting resistance, while an overly light inoculum can result in artificially low MICs, indicating false susceptibility [34]. Furthermore, the move towards colorimetric assays, which use oxidation-reduction indicators like INT to provide a visual or spectrophotometric signal of microbial growth, demands even greater precision in inoculum preparation to ensure accurate and objective endpoint determination [35] [36].

This application note provides a detailed, step-by-step protocol for inoculum preparation and standardization, aligned with guidelines from the European Committee on Antimicrobial Susceptibility Testing (EUCAST) [4] [28] and the Clinical and Laboratory Standards Institute (CLSI) [36]. The procedures are contextualized for research aimed at developing and optimizing colorimetric MIC assays.

Experimental Workflow

The following diagram illustrates the complete workflow for broth microdilution MIC determination, highlighting the critical stages of inoculum preparation.

Materials and Reagents

Research Reagent Solutions

Table 1: Essential materials and reagents for broth microdilution inoculum preparation.

| Item | Function/Description | Key Considerations |

|---|---|---|

| Cation-Adjusted Mueller Hinton Broth (CAMHB) | Standard growth medium for non-fastidious aerobic bacteria [28]. | For fastidious organisms, use supplemented broth (e.g., MH-F broth) [4]. |

| Sterile 0.85% Saline Solution | Diluent for adjusting bacterial suspension turbidity and performing serial dilutions [28]. | Must be isotonic to prevent osmotic shock to bacterial cells. |

| McFarland Turbidity Standards | Reference for standardizing the density of the bacterial inoculum [34]. | The 0.5 McFarland standard is equivalent to ~1-2 x 10⁸ CFU/mL for E. coli [34]. |

| 96-Well Microtiter Plate | Platform for broth microdilution assay. | Use sterile, U-bottom or flat-bottom plates compatible with plate readers [37]. |

| Antimicrobial Agent Stock Solutions | Source of the antimicrobial compound being tested. | Prepare at high concentration (e.g., 1000 µg/mL or 10x the highest test concentration) [34]. Filter-sterilize and store at ≤ -20°C. |

| INT or other Colorimetric Reagent | Oxidation-reduction indicator for visual growth detection. | Added post-incubation or incorporated into the medium. Turns from yellow to pink/red in the presence of microbial growth [35]. |

Protocol: Inoculum Preparation and Standardization

Preparation of Overnight Culture

- Day 1: Using a sterile inoculation loop, pick 3-5 well-isolated colonies from a fresh (18-24 hour) agar plate culture.

- Transfer the colonies into a tube containing 4-5 mL of appropriate broth medium (e.g., Mueller Hinton Broth).

- Incubate the broth culture for 16-20 hours at 35±2°C under ambient air with constant agitation at 220 RPM [28].

Standardization of Inoculum Density

- Day 2: Vortex the overnight culture thoroughly to ensure a homogeneous suspension.

- Transfer a portion of the culture to a sterile tube or cuvette.

- Adjust the turbidity of the suspension to match that of a 0.5 McFarland standard. This results in a suspension containing approximately 1-2 x 10⁸ CFU/mL for organisms like Escherichia coli [34] [28].

- Comparison can be performed visually against a McFarland card with contrasting lines or using a densitometer for greater precision.

- This standardized suspension must be used within 15-30 minutes of preparation to prevent significant changes in viable count [34].

Preparation of Working Inoculum

- Perform a 1:150 dilution of the adjusted 0.5 McFarland suspension in sterile saline or broth [34] [28].

- This dilution factor is critical and yields a working inoculum concentration of approximately 1 x 10⁶ CFU/mL.

- When this working inoculum is added to the microtiter plate (typically in a 1:1 ratio with the broth/antibiotic solution), the final bacterial density in each test well becomes approximately 5 x 10⁵ CFU/mL, which is the target specified by EUCAST and CLSI guidelines [28] [36].

Inoculation of Microtiter Plate

- Add 100 µL of the working inoculum (from step 4.3) to each well of the microtiter plate containing 100 µL of the serial antibiotic dilutions [34] [37].

- This step results in the desired 1:2 final dilution of both the antibiotic and the inoculum, achieving the target test concentration of ~5 x 10⁵ CFU/mL.

- Include appropriate controls in the plate layout:

- Growth Control Well: Broth + inoculum (no antibiotic).

- Sterility Control Well: Broth only (no inoculum, no antibiotic).

Enumeration of Colony Forming Units (CFU)

To validate the entire process, the actual inoculum density must be verified by colony counting.

Table 2: Colony Count Enumeration for Inoculum Verification.

| Step | Procedure | Target CFU/mL |

|---|---|---|

| 1. Serial Dilution | Perform a logarithmic serial dilution (10⁻¹ to 10⁻⁶) of the standardized 0.5 McFarland suspension in sterile saline [28]. | N/A |

| 2. Plating | Plate 20 µL spots from each dilution onto non-selective agar plates, in triplicate [28]. Alternatively, spread 100 µL of a 10⁻⁵ dilution. | N/A |

| 3. Incubation & Counting | Incubate plates for 18-24 hours. Count the colonies on plates with 30-300 colonies. Calculate the CFU/mL of the original suspension. | ~1-2 x 10⁸ CFU/mL for the 0.5 McFarland standard. ~5 x 10⁵ CFU/mL in the final test well. |

Quality Control and Troubleshooting

Rigorous quality control is essential for reliable MIC data. The following table outlines common issues and solutions related to inoculum preparation.

Table 3: Troubleshooting Guide for Inoculum-Related Issues.

| Problem | Potential Consequence | Corrective Action |

|---|---|---|

| Inconsistent MICs between replicates | Poor reproducibility, unreliable data. | Ensure thorough vortexing of the culture before standardization. Use the inoculum within the recommended 30-minute window [34]. |

| MICs consistently too high | False indication of resistance. | Likely due to an overly heavy inoculum. Verify the McFarland standard preparation and turbidity adjustment method. Confirm dilution calculations [34]. |

| MICs consistently too low | False indication of susceptibility. | Likely due to an overly light inoculum. Check the viability of the culture and ensure the incubation time is not exceeded. Confirm dilution calculations [34]. |

| Skipped wells or uneven growth | Inability to determine a clear MIC endpoint. | Check for contamination. Ensure the inoculum is mixed adequately before pipetting into the plate [34]. |

| Poor color development in colorimetric assays | Ambiguous or false-negative MIC reading. | Confirm the inoculum viability via CFU plating. Ensure the colorimetric reagent is fresh and compatible with the test organism and medium [35]. |

Use of Quality Control Strains

To ensure the entire test system is performing within specified limits, include quality control (QC) strains with known MIC ranges in each assay run. Recommended strains include [34] [28]:

- Escherichia coli ATCC 25922

- Staphylococcus aureus ATCC 29213

- Pseudomonas aeruginosa ATCC 27853

The MIC values obtained for these QC strains must fall within the published acceptable ranges for the test to be considered valid [28].

Integration with Colorimetric MIC Determination

The standardized inoculum protocol is perfectly suited for colorimetric MIC assays. After the standard incubation period (16-20 hours), a metabolically active inoculum will interact predictably with colorimetric reagents:

- Principle: Viable bacteria reduce the tetrazolium salt (INT), which changes from yellow to a visible pink or red formazan product [35] [36].

- Endpoint Determination: The MIC is read as the lowest concentration of antibiotic where the color change is absent, indicating inhibition of metabolic activity. This provides an objective, visual endpoint that can also be quantified using a plate reader [35].

- Advantage: A properly standardized inoculum ensures that the metabolic signal is strong enough to be detected, thereby increasing the accuracy and reliability of the colorimetric readout compared to subjective turbidity assessment.

The INT colorimetric assay is a vital tool in modern antimicrobial susceptibility testing, enabling the precise determination of the Minimum Inhibitory Concentration (MIC) of novel compounds. This method leverages the metabolic activity of viable microorganisms to reduce the pale yellow, water-soluble 2-(4-Iodophenyl)-3-(4-nitrophenyl)-5-phenyl-2H-tetrazolium chloride (INT) to a dark red, water-insoluble formazan product [1]. The ensuing color change provides a clear, quantifiable visual or spectrophotometric endpoint, circumventing the subjectivity associated with traditional turbidity measurements [38] [1]. This application note details a standardized and validated protocol for performing the INT colorimetric microdilution assay, designed to provide researchers with a robust framework for generating reliable and reproducible MIC, IC50%, and IC90% data within the broader context of antimicrobial drug discovery.

Materials and Reagents

Research Reagent Solutions

The following table lists the essential materials required for the successful execution of the INT colorimetric assay.

Table 1: Essential Reagents and Materials for the INT Colorimetric MIC Assay

| Item | Function/Description | Application Notes |

|---|---|---|

| 2,3,5-triphenyltetrazolium chloride (TTC) / INT | Colorimetric viability indicator; reduced by metabolically active cells to a red formazan product [1]. | INT is cited as a common tetrazolium salt for this purpose [1]. The solution is prepared at 0.125% (w/v) in water [38]. |

| Cation-adjusted Mueller Hinton Broth (CAMHB) | Standardized culture medium for bacterial growth [1]. | Used for bacteria (S. aureus, E. coli, P. aeruginosa). |

| Sabouraud Dextrose Broth | Culture medium optimized for yeast growth [1]. | Used for the yeast C. albicans. |

| Sterile 96-well Microtiter Plates | Platform for the microdilution assay. | Allows for testing of multiple compound concentrations and controls simultaneously, saving reagents [38]. |

| Dey-Engley (D/E) Neutralizing Broth | Formulated to inactivate common disinfectants and antiseptics in the test sample [2]. | Contains bromcresol purple as a pH indicator; color change to yellow indicates bacterial growth [2]. Critical for testing compounds like povidone-iodine [2]. |

| Dimethyl Sulfoxide (DMSO) | Solvent for dissolving hydrophobic antimicrobial compounds. | Final concentration in the assay should be ≤1% to avoid antimicrobial effects on the test organisms. |

| Sterile Physiological Saline (0.85-0.90% NaCl) | Diluent for adjusting microbial inoculum density. | - |

Experimental Protocol

Preparation of Inoculum

- Subculture: From fresh stock cultures (20-24 hours old), subculture the test microorganisms—Staphylococcus aureus (ATCC 6538), Escherichia coli (ATCC 8739), Pseudomonas aeruginosa (ATCC 9027), or Candida albicans (ATCC 10231)—onto the appropriate solid agar media [1].

- Suspension: Harvest colonies and prepare a suspension in sterile saline or broth.

- Standardization: Adjust the turbidity of the microbial suspension to match a 0.5 McFarland standard, which equates to approximately 1-5 x 10^8 CFU/mL for bacteria and 1-5 x 10^6 CFU/mL for C. albicans [1].

- Dilution: Further dilute the standardized suspension in the appropriate broth (CAMHB or Sabouraud) to achieve a working concentration that will deliver a final inoculum of approximately 5 x 10^5 CFU/mL per well in the microtiter plate [1].

Plate Inoculation and Setup

- Compound Dilution: In a sterile 96-well microtiter plate, prepare a two-fold serial dilution of the antimicrobial compound directly in the culture broth (100 µL final volume per well). The first well typically contains the highest concentration, with decreasing concentrations in subsequent wells [38] [1].

- Inoculation: Add 10 µL of the prepared standardized inoculum to all test wells and growth control wells [1].

- Controls: Include the following controls on each plate:

- Growth Control: Wells containing broth and inoculum only (no antimicrobial compound).

- Sterility Control: Wells containing broth only (no inoculum, no compound).

- Compound Control (Optional): Wells containing the highest concentration of the compound in broth (no inoculum) to confirm the compound does not cause interference in the colorimetric reading.

Incubation Parameters

- Orientation: Incubate the microtiter plates in an inverted position (agar up) to prevent condensation from dripping onto the agar surface and disrupting the microbial growth [39].

- Temperature and Duration: Incubate the plates at 35 ± 2 °C for a period of 22 hours [38] [1]. Incubating below human body temperature (30°C or lower) reduces the risk of cultivating human pathogens [39].

- Atmosphere: Incubate under aerobic conditions. Plates should not be completely sealed; instead, secure the lid with 2-4 short strips of adhesive tape at opposite edges to prevent accidental opening while allowing oxygen diffusion [39].

Colorimetric Development and Reading

- INT Addition: After the 22-hour incubation period, add 20 µL of 0.125% (w/v) INT solution to each well [38] [1].

- Secondary Incubation: Return the plates to the incubator for an additional 2 hours at 35 °C to allow for color development [38].

- Endpoint Determination:

- Visual Reading: The MIC is defined as the lowest concentration of the antimicrobial compound that prevents a color change from yellow to dark red. A clear well indicates no microbial growth and full inhibition [1].

- Spectrophotometric Reading: For quantitative determination of IC50% and IC90%, measure the absorbance of the formazan product at a suitable wavelength (e.g., 490-540 nm) using a microplate reader. The absorbance is directly proportional to the quantity of viable cells [38] [1].

Diagram 1: INT colorimetric MIC assay workflow

Data Interpretation and Analysis

Defining Key Metrics

The validated colorimetric method allows for the conversion of absorbance values into quantitative measures of antimicrobial potency [38].

Table 2: Key Quantitative Metrics in Antimicrobial Susceptibility Testing

| Metric | Definition | Interpretation |

|---|---|---|

| Minimum Inhibitory Concentration (MIC) | The lowest concentration of an antimicrobial agent that visually inhibits the growth of a microorganism (prevents color change to red) [38] [1]. | A lower MIC indicates greater potency of the antimicrobial agent against the test organism. |

| Half-Maximal Inhibitory Concentration (IC50%) | The concentration of an antimicrobial that reduces the microbial growth (as measured by formazan absorbance) by 50% compared to the growth control [38]. | Provides a quantitative measure of compound potency, useful for comparing different agents. |

| 90% Inhibitory Concentration (IC90%) | The concentration of an antimicrobial that reduces the microbial growth by 90% compared to the growth control [38]. | Indicates the concentration required for near-complete inhibition of the microbial population. |

Method Validation Parameters

The INT colorimetric microdilution assay should be validated to ensure data reliability. Key validation parameters include [38]:

- Linearity: A coefficient of determination (R²) greater than 0.95 confirms a direct correlation between absorbance and viable microbial concentration (CFU mL⁻¹).

- Precision: A relative standard deviation (RSD) of less than 26% demonstrates acceptable repeatability.

- Accuracy: Recovery rates between 75% and 122% ensure the method yields results close to the true value.

Troubleshooting and Best Practices

Table 3: Common Issues and Resolution Strategies in the INT Assay

| Issue | Potential Cause | Recommended Solution |

|---|---|---|

| No color change in growth control wells. | Non-viable inoculum, incorrect incubation temperature, INT solution degradation. | Check inoculum viability on agar plates, verify incubator temperature, prepare fresh INT solution [1]. |

| Excessive or rapid color development. | Inoculum concentration too high. | Re-standardize the inoculum to the 0.5 McFarland standard and verify dilution factors [1]. |

| Color development in sterility control. | Contamination of reagents or plates. | Use sterile technique, ensure all reagents and equipment are sterile. |

| High background in compound control wells. | Compound interference with the INT dye. | Include a neutralization step (e.g., using D/E Neutralizing Broth) for colored or reactive compounds like povidone-iodine [2]. |

| Poor reproducibility between replicates. | Inconsistent pipetting or inoculum preparation. | Use calibrated pipettes and ensure the inoculum is a homogeneous suspension before transfer. |

Colorimetric assays are fundamental tools in biological research and drug development, providing a means to quantify biological and chemical reactions through visual color changes or spectrophotometric analysis. These assays are particularly valuable in determining the Minimum Inhibitory Concentration (MIC) of antimicrobial agents, a critical parameter in pharmaceutical development and microbiology. The core principle relies on the measurement of light absorbance by a colored compound, the formation of which is directly proportional to the concentration of the analyte or the activity of a biological system [40]. This document provides detailed application notes and protocols for implementing colorimetric detection within the context of INT colorimetric assay-based MIC determination, enabling researchers to accurately assess microbial viability and metabolic activity.

Core Principles and Assay Configuration

Colorimetric detection functions by establishing a direct relationship between the concentration of an analyte in a solution and its light absorbance at a specific wavelength, as described by Beer's Law [40]. In the specific context of INT (2-(4-Iodophenyl)-3-(4-nitrophenyl)-5-phenyl-2H-tetrazolium chloride) assays for MIC determination, the fundamental mechanism involves the enzymatic reduction of the nearly colorless INT substrate to a brightly colored, pink-red formazan product by metabolically active microbial cells [41]. The intensity of the resulting color is therefore directly proportional to the number of viable, metabolically active cells present, providing a quantitative measure of cell proliferation or, conversely, the inhibitory effects of antimicrobial compounds.

Proper configuration of the assay is essential for accurate results. This involves selecting appropriate wavelengths, preparing a standard curve, and understanding the limits of detection. The standard curve is a critical component, transforming raw absorbance values into meaningful concentration data [40].

Table 1: Key Configuration Parameters for INT-MIC Colorimetric Assay

| Parameter | Description | Typical Configuration for INT-MIC |

|---|---|---|

| Detection Principle | Measurement of formazan dye produced by microbial reduction of INT | Metabolic activity of viable cells [41] |

| Primary Wavelength | Absorbance maximum for the formazan product | 490 nm (recommended optimization) |

| Standard Curve | Plot of absorbance vs. known cell count or metabolic standard | Essential for quantification [40] |

| Linear Range | The range of analyte concentration where absorbance is linearly proportional | Must be determined empirically for each microbe |

| Limit of Detection (LOD) | The lowest analyte concentration that can be reliably detected | Must be established [40] |

Research Reagent Solutions and Essential Materials

A successful INT-MIC assay requires specific reagents and materials to ensure consistency, accuracy, and reproducibility. The following toolkit details the core components.

Table 2: Essential Research Reagent Solutions and Materials for INT-MIC Assay

| Item | Function/Description | Application Note |

|---|---|---|

| INT Solution | Tetrazolium salt substrate; reduced by active microbial dehydrogenases to pink-red formazan. | Prepare fresh or store frozen aliquots; final concentration must be optimized for specific microorganisms. |

| Test Compound/ Drug | The antimicrobial agent for which the MIC is being determined. | Serially diluted in a suitable solvent that does not inhibit microbial growth. |

| Microbial Inoculum | Standardized suspension of the target microorganism. | Adjust to a specific density (e.g., 0.5 McFarland) for consistent baseline metabolic activity. |

| Growth Medium | Culture medium supporting microbial growth. | Must be compatible with both the microbe and the colorimetric reaction (e.g., phenol-red free). |

| Positive Control | Medium with microbial inoculum but no drug. | Represents 100% metabolic activity. |

| Negative Control | Medium without inoculum. | Accounts for background absorbance of the medium and reagents. |

| Spectrophotometer/ Microplate Reader | Instrument for measuring absorbance of the formazan product. | Must be capable of reading at the appropriate wavelength (e.g., 490 nm). |

| 96-well Microtiter Plate | Platform for conducting the assay with drug dilutions and replicates. | Flat-bottom plates are ideal for absorbance measurements [42]. |

Experimental Protocol for INT-MIC Determination

The following diagram illustrates the logical workflow for the INT-MIC determination assay, from preparation to data analysis.

Detailed Step-by-Step Methodology

Step 1: Preparation of Drug Dilutions Prepare a stock solution of the test antimicrobial agent. Using a 96-well microtiter plate, perform a two-fold serial dilution of the drug in the appropriate growth medium. A typical range is from 128 µg/mL to 0.125 µg/mL or wider, depending on the expected potency. Each concentration should be tested in duplicate or triplicate.

Step 2: Inoculation Prepare a standardized suspension of the target microorganism (e.g., bacteria or yeast) in growth medium, typically adjusted to a 0.5 McFarland standard. Add a consistent volume of this inoculum to all test wells and control wells, ensuring a final cell density that is within the linear range of the assay (e.g., ~1 x 10^5 CFU/mL for bacteria). The positive control wells receive inoculum but no drug, while the negative control wells receive medium only.

Step 3: Initial Incubation Incubate the sealed microtiter plate under optimal conditions for the microorganism (e.g., 35±2°C for 18-24 hours for most bacteria). This allows the drug to interact with the growing cells.