HPTLC Fingerprinting for Standardization of Bioactive Antimicrobial Compounds: A Comprehensive Guide for Pharmaceutical Analysis

This article provides a comprehensive examination of High-Performance Thin-Layer Chromatography (HPTLC) as a robust analytical tool for standardizing bioactive antimicrobial compounds from natural products.

HPTLC Fingerprinting for Standardization of Bioactive Antimicrobial Compounds: A Comprehensive Guide for Pharmaceutical Analysis

Abstract

This article provides a comprehensive examination of High-Performance Thin-Layer Chromatography (HPTLC) as a robust analytical tool for standardizing bioactive antimicrobial compounds from natural products. Targeting researchers, scientists, and drug development professionals, it covers foundational principles, methodological applications, troubleshooting approaches, and validation protocols. The content explores HPTLC's advantages in quality control, including its cost-effectiveness, high throughput capabilities, and compatibility with bioautography for direct antimicrobial activity detection. By integrating recent research findings and standardized procedures, this guide serves as a practical resource for ensuring reproducibility, safety, and efficacy in the development of herbal antimicrobial formulations, addressing the growing need for reliable standardization methods in natural product research.

Fundamentals of HPTLC Fingerprinting for Antimicrobial Compound Analysis

Principles and Advantages of HPTLC in Natural Product Standardization

In the field of natural product research, the standardization of complex botanical extracts is paramount to ensure their quality, efficacy, and safety. High-performance thin layer chromatography (HPTLC) has emerged as a powerful, sophisticated instrumental technique ideally suited for this task. Based on the full capabilities of thin layer chromatography, HPTLC provides a robust, simple, rapid, and efficient tool for the quantitative and qualitative analysis of complex mixtures found in pharmaceuticals, natural products, and clinical samples [1]. For researchers focusing on bioactive antimicrobial compounds from natural sources, HPTLC offers a unique combination of flexibility, cost-efficiency, and the ability to generate characteristic fingerprints that serve as chemical signatures for authentication and quality control purposes.

Core Principles of HPTLC

HPTLC operates on the same fundamental principles as classical TLC but incorporates significant enhancements that dramatically improve its analytical performance. The technique involves the separation of components in a mixture based on their differential partitioning between a stationary phase and a mobile phase.

Enhanced Stationary Phases

A key advancement in HPTLC is the use of higher quality TLC plates with finer, more uniform particle sizes (typically 5-7 μm) in the stationary phase, which allows for better resolution and separation efficiency. These plates are typically composed of silica gel GF254, though other modified sorbents are also available for specific applications [1] [2]. The particle size and distribution are optimized to provide a more homogeneous layer, resulting in improved reproducibility and sharper separation zones.

Automated Sample Application

HPTLC utilizes automated sample applicators such as the Camag Linomat V, which enables precise, reproducible application of samples as narrow bands rather than spots. This automated application significantly enhances resolution, quantitative accuracy, and the overall reproducibility of the analysis [2].

Advanced Development Techniques

The separation can be further improved by controlled development in automated developing chambers and by repeated development of the plate using a multiple development device. These controlled conditions minimize the influence of environmental factors and contribute to the high reproducibility of HPTLC methods [1].

Sophisticated Detection and Documentation

Visual detection is suitable for qualitative analysis, but HPTLC offers a range of more specific detection methods for quantitative analysis and structural information. These include UV, diode-array and fluorescence spectroscopy, mass spectrometry (MS), Fourier-transform infrared (FTIR), and Raman spectroscopy, all of which have been applied for the in situ detection of analyte zones on a TLC plate [1]. The results can be documented as images, providing a permanent record of the analysis.

Key Advantages of HPTLC in Natural Product Standardization

HPTLC offers numerous distinct advantages that make it particularly valuable for the standardization of natural products, especially when researching bioactive antimicrobial compounds.

Table 1: Advantages of HPTLC in Natural Product Analysis

| Advantage | Description | Relevance to Natural Products |

|---|---|---|

| High Sample Throughput | Parallel analysis of multiple samples on the same plate [1] | Rapid screening of numerous plant extracts or fractions |

| Minimal Sample Preparation | Requires less extensive clean-up compared to other chromatographic methods [1] | Ideal for complex plant matrices containing multiple compound classes |

| Cost-Efficiency | Lower operational costs due to minimal solvent consumption and reusable plates | Economical for routine analysis in quality control laboratories |

| Multiple Detection Options | Sequential application of different derivatization reagents on the same plate [3] | Comprehensive profiling of various phytochemicals with different chemical properties |

| Image-Based Results | Ability to present results as an image providing visual fingerprint [1] | Easy comparison of sample profiles against reference standards |

| Flexibility in Analysis | Open chromatographic system allowing post-chromatographic derivatization [4] | Enhanced detection of specific compound classes through chemical reactions |

HPTLC has established itself as the method of choice for handling complex analytical tasks involving herbal drugs and botanicals. The unique combination of state-of-art instrumentation, standardized procedures, and solid theoretical foundations enables it to deliver reliable, cGMP-compliant results time after time [1]. It remains one of the most flexible, reliable, and cost-efficient separation techniques ideally suited for the analysis of botanicals and herbal drugs, guaranteeing reproducible results—a vital element in the routine identification of complex fingerprints of plant extracts and pharmaceutical products [1].

For antimicrobial research specifically, HPTLC enables the correlation of specific compound bands with antimicrobial activity through bioautography, where the developed plate is incubated with microbial cultures to detect zones of inhibition. This direct linking of chemical profiles with biological activity is particularly valuable in natural product drug discovery.

Applications in Standardization of Antimicrobial Natural Products

The application of HPTLC in standardizing natural products with antimicrobial potential is well-established in scientific literature. The technique serves multiple purposes from authentication to quantification of active markers.

Fingerprinting for Authentication and Quality Control

HPTLC fingerprinting generates characteristic patterns that serve as chemical signatures for herbal materials. This is particularly important for establishing the identity and purity of antimicrobial plant extracts. A recent study established characteristic HPTLC fingerprints for rooibos (Aspalathus linearis) and honeybush (Cyclopia species) teas, allowing for their authentication and quality control. The optimized method provided adequate resolution and clearly visible bands for phenolic compounds including orientin, vitexin, rutin, quercetin, mangiferin, and isomangiferin, which can serve as marker compounds [3].

Quantification of Bioactive Compounds

HPTLC, when coupled with densitometry, provides accurate quantification of antimicrobial compounds in natural products. The analysis of Nymphaea nouchali seeds, used in traditional medicine for infections, demonstrated this application effectively. Researchers developed and validated an HPTLC method to quantify three phenolic compounds with known antimicrobial activity: catechin (3.06%), gallic acid (0.27%), and quercetin (0.04%) [2]. The high catechin content correlated with the significant antimicrobial activity observed against pathogens including Pseudomonas aeruginosa, Staphylococcus aureus, and Candida albicans [2].

Table 2: HPTLC Analysis of Antimicrobial Compounds in Natural Products

| Natural Product | Bioactive Compounds Quantified | Antimicrobial Activity Correlated | Reference |

|---|---|---|---|

| Nymphaea nouchali seeds | Catechin (3.06%), Gallic acid (0.27%), Quercetin (0.04%) | Effective against P. aeruginosa, S. aureus, C. albicans [2] | [2] |

| Photinia integrifolia root bark | Diterpenoids (1β,3α,8β-trihydroxy-pimara-15-ene, 6α,11,12,16-tetrahydroxy-7-oxo-abieta-8,11,13-triene, 2α,19-dihydroxy-pimara-7,15-diene) | Chemical markers for standardization [1] | [1] |

| Bamboo-leaf flavonoids | Isoorientin, isovitexin, orientin, vitexin | Standardization of commercial samples [1] | [1] |

Detection of Adulteration

HPTLC serves as an ideal screening tool for adulterations in natural products and is highly suitable for evaluating and monitoring cultivation, harvesting, and extraction processes [1]. The CAMAG application notes include methods for "Detecting adulteration with olive leaves in oregano herb" and "Detection of paraffin oil in milk," demonstrating the versatility of HPTLC in detecting various types of adulteration [4].

Experimental Protocols for HPTLC Fingerprinting

This section provides a detailed methodology for developing HPTLC fingerprints of natural products with antimicrobial properties, based on established protocols from the literature.

Sample Preparation Protocol

- Plant Material Processing: Reduce the dried plant material to a coarse powder using a mechanical grinder.

- Extraction: Weigh approximately 2.0 g of the powdered material and extract with 20 mL of 70% ethanol using a Soxhlet apparatus at 50°C for 6 hours [2].

- Concentration: Evaporate the extract to dryness using a rotary evaporator at 50°C.

- Reconstitution: Dissolve the residue in 10 mL of methanol and filter through a 0.45 μm membrane filter before application on HPTLC plates.

HPTLC Analysis Protocol

- Stationary Phase: Use pre-coated silica gel GF254 HPTLC plates (20 × 10 cm) [2].

- Sample Application: Apply samples and standards as bands (8 mm in length) using an automated TLC sample spotter (e.g., Camag Linomat V) at a constant application rate of 150 nL/s [2].

- Chromatographic Development: Develop the plates in a Camag glass twin-trough chamber previously saturated with the mobile phase for 20 minutes. The mobile phase should be optimized for the specific natural product under investigation. For phenolic compounds, a suitable system is chloroform:ethyl acetate:formic acid:methanol (2.5:2:0.4:0.2, v/v/v/v) [2].

- Development Distance: Allow the mobile phase to migrate vertically to a distance of 80 mm from the point of application.

- Drying: Air-dry the developed plates in a fume hood.

Derivatization and Detection

- Visualization Reagents: Use appropriate derivatization reagents such as:

- Derivatization Method: Dip the developed and dried plates in the derivatization reagent for 2 seconds, then heat at 100°C for 3-5 minutes to develop the colors.

- Documentation: Capture the images under white light, UV light at 254 nm, and UV light at 366 nm using a documentation system.

- Densitometric Scanning: For quantification, perform densitometric scanning at appropriate wavelengths (e.g., 412 nm for quercetin) [2].

Method Validation

For quantitative analysis, validate the HPTLC method according to International Conference on Harmonization (ICH) guidelines for:

- Linearity (e.g., concentration range of 100-1000 ng/band for standards)

- Precision (intra-day and inter-day relative standard deviation <2%)

- Accuracy (recovery studies 98-102%)

- Robustness (deliberate variations in mobile phase composition, development distance, etc.)

- Limit of Detection (LOD) and Limit of Quantification (LOQ) [1]

Essential Research Reagent Solutions

Successful HPTLC analysis requires specific reagents and materials to ensure reproducible and accurate results. The following table outlines key reagents and their functions in HPTLC workflow for natural product standardization.

Table 3: Essential Research Reagents for HPTLC Analysis of Natural Products

| Reagent/Material | Function in HPTLC Analysis | Application Example |

|---|---|---|

| Silica gel GF254 plates | Stationary phase for chromatographic separation | Standard matrix for most natural product separations [2] |

| Natural Product (NP) reagent | Derivatization for visualization of flavonoids | Detection of quercetin, orientin, vitexin in plant extracts [3] |

| p-Anisaldehyde sulfuric acid reagent | Universal derivatization for various phytochemicals | Visualization of terpenes, steroids, and other compounds [3] |

| Methanol, Ethanol | Extraction solvents for plant materials | Preparation of plant extracts prior to HPTLC analysis [2] |

| Chloroform, Ethyl Acetate, Formic Acid | Components of mobile phase systems | Separation of phenolic compounds in antimicrobial plants [2] |

| Standard compounds (e.g., quercetin, gallic acid, catechin) | Reference markers for identification and quantification | Quantification of antimicrobial phenolics in Nymphaea nouchali [2] |

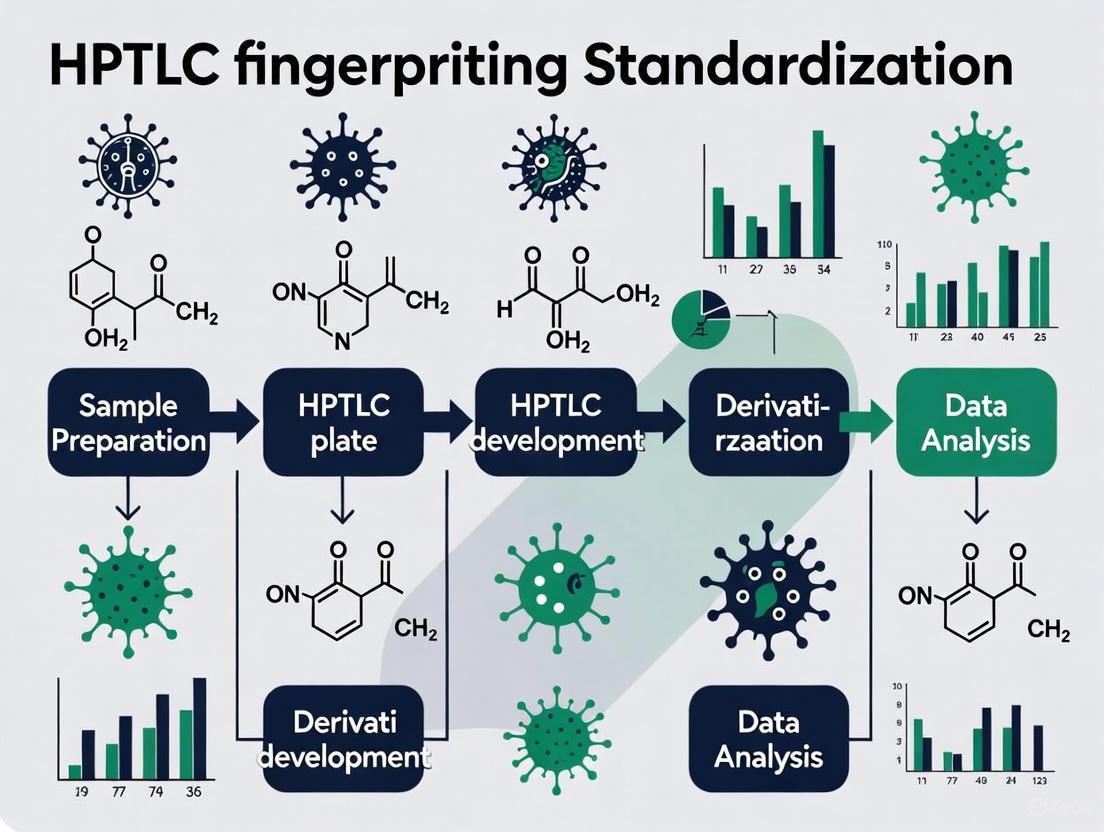

Workflow Visualization

The following diagram illustrates the complete HPTLC workflow for natural product standardization, from sample preparation to documentation and analysis:

HPTLC Standardization Workflow

HPTLC represents a powerful, versatile, and cost-effective analytical platform for the standardization of natural products, particularly those with antimicrobial properties. Its unique advantages including high sample throughput, minimal sample preparation, multiple detection capabilities, and the ability to generate visual fingerprints make it an indispensable tool in natural product research. The principles of enhanced stationary phases, automated sample application, controlled development, and sophisticated detection methods underpin its superior performance compared to traditional TLC. As demonstrated in various applications, HPTLC enables researchers to establish characteristic fingerprints, quantify bioactive markers, detect adulteration, and correlate chemical profiles with biological activity—all essential components of a comprehensive standardization strategy for antimicrobial natural products.

High-performance thin-layer chromatography (HPTLC) is a sophisticated, robust, simple, rapid, and efficient analytical technique widely employed for the separation, identification, and quantification of non-volatile compounds [5]. As an advanced form of thin-layer chromatography (TLC), HPTLC utilizes stationary phases with finer particle sizes, leading to superior resolution, enhanced compound separation, and lower limits of detection (LOD) [5] [1]. This technique is particularly valuable in pharmaceutical and natural product research for its ability to provide chromatographic fingerprints, which are essential for the standardization of complex mixtures such as plant extracts containing bioactive antimicrobial compounds [6] [1]. For researchers focused on drug discovery, HPTLC offers unique advantages including minimal sample preparation, high sample throughput, and the possibility of multiple detection methods and hyphenation [5] [1]. This application note details validated HPTLC methodologies for the analysis of three key classes of bioactive compounds—alkaloids, flavonoids, and terpenoids—within the context of antimicrobial compound research and development.

HPTLC Fundamentals and Relevance to Bioactive Compound Analysis

HPTLC operates on the same fundamental principles as TLC but with enhancements that significantly improve its analytical performance. The three primary modes of HPTLC are linear, circular, and anticircular, with the anticircular mode being the fastest and most cost-effective, offering superior separation and sensitivity, especially at higher Rf values [5]. The technique is highly regarded for its flexibility, reliability, and cost-efficiency, making it an ideal choice for generating reproducible fingerprints of botanicals and herbal drugs [1]. A key strength in bioactive compound research is its ability to combine chromatographic separation with effect-directed detection using biological assays, thereby helping researchers select important compounds from complex samples for further characterization [5]. The following diagram illustrates a generalized HPTLC workflow for bioactive compound analysis.

Analysis of Key Bioactive Compound Classes

Alkaloids

Alkaloids are nitrogen-containing secondary metabolites with demonstrated antimicrobial properties. HPTLC provides a rapid and reliable method for their profiling and quantification in complex matrices.

Protocol: HPTLC Analysis of Ephedrine Alkaloids [7]

- Stationary Phase: Silica gel 60 F254 HPTLC plates.

- Sample Preparation: Ultrasonicate 1 g of powdered plant material with 10 mL of methanol/water (2:1, v/v) for 15 minutes. Filter the extract before application.

- Application: Apply 10 µL of standard and sample solutions as 8-mm bands using an automated sampler (e.g., CAMAG Linomat 5).

- Mobile Phase: Ammonia/methanol/dichloromethane (1:10:40, v/v/v).

- Development: Develop the plate in a twin-trough chamber pre-saturated with the mobile phase for 20 minutes. The development distance is 80 mm.

- Derivatization: Spray the developed plate with ninhydrin reagent (0.2% in ethanol) and heat at 105°C for 5-10 minutes until violet-colored bands appear.

- Detection & Quantification: Scan the plate densitometrically at 500 nm. Identify ephedrine by comparing its Rf value and UV spectrum with a reference standard.

Application Note: A validated HPTLC method for ephedrine alkaloids demonstrated a linearity range of 0.062-0.146 µg/band, with an LOD of 0.0020 µg/band and LOQ of 0.0067 µg/band [7]. This method allows for the simultaneous screening of up to 19 samples on a single plate, making it highly efficient for quality control.

Flavonoids

Flavonoids are polyphenolic compounds known for their broad-spectrum antimicrobial and antioxidant activities. HPTLC is particularly effective for their fingerprinting and quantification.

Protocol: HPTLC Analysis of Flavonoids using Derivatization [6] [8]

- Stationary Phase: Silica gel 60 F254 HPTLC plates.

- Sample Preparation: Extract 1 g of powdered leaf or flower material with 10 mL of methanol using ultrasound-assisted extraction for 15-20 minutes. Filter before use.

- Application: Apply standard and sample solutions as bands.

- Mobile Phase (for flavonoid separation): Toluene : ethyl acetate : formic acid : methanol (20:12:8:4, v/v/v/v).

- Development: Develop the plate in a saturated twin-trough chamber.

- Derivatization:

- AlCl3 Method: Spray the plate with a 2% ethanolic AlCl3 solution. Heat at 100°C for 1-2 minutes. Observe under UV 366 nm.

- NaNO2-AlCl3-NaOH Method: Sequentially spray with NaNO2, AlCl3, and NaOH solutions [8].

- Detection: Document the plate under UV light at 366 nm before and after derivatization. Perform densitometric scanning at the respective λmax (typically 370-420 nm after AlCl3 derivatization).

Application Note: Derivatization with AlCl3 causes bathochromic shifts in the absorbance maxima of most flavonoids, enabling their selective detection. This method helps visualize individual flavonoids, complementing the total flavonoid content assay and aiding in the authentication of antimicrobial plant extracts [8].

Terpenoids

Terpenoids constitute a large class of natural products with significant antimicrobial and anti-inflammatory activities. HPTLC fingerprinting is valuable for their chemotaxonomic and standardization studies.

Protocol: HPTLC for Chemotaxonomic Investigation of Terpenoids [9]

- Stationary Phase: Aluminum sheets coated with silica gel 60 F254.

- Sample Preparation: Extract plant material (e.g., bark) with an appropriate solvent like methanol or dichloromethane.

- Application: Apply crude extracts and standards as bands using an automated sampler.

- Mobile Phase: Optimize based on the terpenoid class under investigation. Common systems include hexane-ethyl acetate or toluene-ethyl acetate mixtures in varying ratios.

- Development: Develop the plate in a flat-bottom or twin-trough chamber.

- Detection: Document the plate under UV 254 nm and 366 nm. Derivatize with specific reagents like anisaldehyde-sulfuric acid or vanillin-sulfuric acid, followed by heating, to visualize terpenoids as colored zones.

- Data Analysis: Use chemometric tools like Principal Component Analysis (PCA) and Hierarchical Cluster Analysis (HCA) to classify plant species based on their terpenoid profiles.

Application Note: HPTLC, combined with chemometric analysis, is a powerful strategy for identifying chemotypes within plant species based on variations in their terpenoid content. This integrated approach confirms the presence of chemotypes and identifies potential phytomarkers of taxonomic and therapeutic importance [9].

Table 1: Summary of HPTLC Conditions for Key Bioactive Compound Classes

| Parameter | Alkaloids (e.g., Ephedrine) [7] | Flavonoids [6] [8] | Terpenoids [9] |

|---|---|---|---|

| Stationary Phase | Silica gel 60 F254 | Silica gel 60 F254 | Silica gel 60 F254 |

| Sample Application | Automated, 10 µL as bands | Automated band application | Automated band application |

| Mobile Phase | NH3/MeOH/DCM (1:10:40, v/v/v) | Toluene:EtOAc:FA:MeOH (20:12:8:4, v/v) | Hexane:EtOAc or similar |

| Derivatization | Ninhydrin reagent, heating | AlCl3 or NaNO2-AlCl3-NaOH | Anisaldehyde-H2SO4, heating |

| Detection | Densitometry at 500 nm | UV 366 nm, densitometry at ~400 nm | Visible light, UV 366 nm |

| Linearity Range | 0.062 - 0.146 µg/band | Compound-dependent | - |

| LOD/LOQ | 0.0020 / 0.0067 µg/band | Compound-dependent | - |

Table 2: Research Reagent Solutions for HPTLC Analysis

| Reagent / Material | Function in HPTLC Analysis |

|---|---|

| HPTLC Plates (Silica gel 60 F254) [5] | The stationary phase for compound separation; the F254 indicator fluoresces under UV 254 nm for compound visualization. |

| Automated Sample Applicator (e.g., CAMAG Linomat 5) [5] | Provides precise, automated sample application as narrow bands, enhancing resolution and reproducibility. |

| Twin-Trough Development Chamber [5] | A saturated chamber for chromatogram development, ensuring reproducible and optimal separation conditions. |

| Aluminium Chloride (AlCl3) Reagent (2%) [8] | Derivatization agent for flavonoids; forms acid-stable complexes, causing bathochromic shifts for selective detection. |

| Ninhydrin Reagent (0.2%) [7] | Derivatization agent for primary amine-containing compounds like certain alkaloids (e.g., ephedrine), producing colored derivatives. |

| Anisaldehyde-Sulfuric Acid Reagent [9] | A general derivatization reagent for terpenoids, producing characteristic colors upon heating. |

| HPTLC Densitometer Scanner (e.g., CAMAG TLC Scanner 4) [9] | Enables in-situ quantification and spectral analysis of separated bands directly on the plate. |

Advanced Applications and Hyphenation

HPTLC's versatility is greatly enhanced by its compatibility with advanced data analysis and hyphenation techniques. For antimicrobial research, combining HPTLC with effect-directed analysis (EDA) allows for the direct correlation of separated chemical bands with biological activity, such as antibacterial or antifungal effects [5] [6]. Furthermore, hyphenation with techniques like mass spectrometry (HPTLC-MS) or Fourier-transform infrared spectroscopy (HPTLC-FTIR) provides structural information for the unequivocal identification of antimicrobial compounds [5] [10]. The application of chemometric analysis (e.g., PCA, HCA) to HPTLC densitometric profiles enables the classification of plant species based on their metabolite fingerprints and the identification of chemotypes, which is crucial for ensuring the consistent quality of raw materials used in drug development [9]. The logical pathway from screening to compound identification is summarized below.

HPTLC has established itself as a powerful, versatile, and cost-effective analytical platform for the standardization of bioactive antimicrobial compounds from natural sources. Its ability to provide high-resolution chromatographic fingerprints for alkaloids, flavonoids, and terpenoids—coupled with options for facile derivatization, precise quantification, and advanced hyphenation—makes it an indispensable tool in the modern researcher's arsenal. The detailed protocols and application notes provided herein offer a solid foundation for scientists and drug development professionals to implement HPTLC in their workflows for the reliable and reproducible analysis of complex plant-derived formulations aimed at combating microbial infections.

Within the pipeline for antimicrobial drug discovery, particularly from complex natural products, the choice of analytical technique is pivotal. High-Performance Thin-Layer Chromatography (HPTLC) has emerged as a powerful, versatile platform that addresses specific challenges in the screening and standardization of antimicrobial compounds. Unlike methods that provide only chemical data, HPTLC uniquely integrates chemical separation with direct biological activity detection, offering a functional perspective essential for identifying genuine bioactive constituents. This application note details the comparative advantages of HPTLC and provides established protocols for its use in antimicrobial screening, supporting the broader thesis that HPTLC fingerprinting is a robust methodology for standardizing bioactive antimicrobial compounds.

Comparative Analysis: HPTLC Versus Other Chromatographic Techniques

The selection of an analytical method balances throughput, cost, information depth, and applicability to biological screening. The table below provides a structured comparison of HPTLC with other common chromatographic methods in the context of antimicrobial compound research.

Table 1: Quantitative comparison of chromatographic techniques for antimicrobial screening

| Feature | HPTLC | HPLC | GC-MS | LC-MS |

|---|---|---|---|---|

| Analysis Time | 5–15 minutes for multiple samples [11] | Often >30 minutes per sample [11] | 15-60 minutes per sample | 15-60 minutes per sample |

| Sample Throughput | High (parallel analysis of up to 20 samples/plate) [11] | Low (sequential analysis) | Low (sequential analysis) | Low (sequential analysis) |

| Solvent Consumption | Low (<10 mL per run) [11] | High (hundreds of mL to L/day) | Moderate | High |

| Sample Pretreatment | Minimal often required [11] | Often labor-intensive [11] | Can be complex | Can be complex |

| Direct Bioactivity Linking | Yes (via bioautography) | Indirect (fraction collection required) | No | Indirect |

| Detection Flexibility | Multiple: UV/Vis, MS, SERS, bioassay on same plate [11] | Typically single detector (e.g., DAD) | Mass spectrometry | Mass spectrometry |

| Cost per Analysis | Low | High | High | Very High |

| Key Advantage for Antimicrobial Screening | Direct, in-situ bioautography for activity-based profiling [12] | High resolution and precision for quantification | Excellent for volatile antimicrobials | Powerful identification of non-volatile compounds |

As illustrated, HPTLC offers distinct benefits in speed, cost-effectiveness, and environmental impact due to its low solvent consumption [11]. Its most significant advantage for antimicrobial discovery is the seamless integration with bioautography, a technique that allows for the direct localization of antibacterial or antifungal compounds on the chromatogram itself.

Core Experimental Protocols for Antimicrobial Screening via HPTLC

Protocol 1: HPTLC Fingerprinting and Bioautography

This protocol is designed to separate components of a complex extract, such as a polyherbal formulation, and identify those with antimicrobial activity [12].

Workflow Overview:

Materials and Reagents:

- HPTLC Plates: Silica gel 60 F254, 20x10 cm (e.g., Merck) [13].

- Sample: Methanolic extract of test material (e.g., polyherbal formulation) [12].

- Mobile Phase: Varies by sample; for example, Toluene: Ethyl acetate: Glacial acetic acid (4:5:1, v/v) [14].

- Microbial Strain: Test organisms like Staphylococcus aureus (Gram-positive) or Escherichia coli (Gram-negative) [12].

- Growth Medium: Mueller Hinton Agar (MHA) and Mueller Hinton Broth (MHB) [12].

- Visualization Reagent: Iodonitrotetrazolium chloride (INT) or MTT for dyeing microbial growth [12].

Procedure:

- Sample Application:

Chromatographic Development:

- Pour the mobile phase into a twin-trough chamber to a depth of about 5 mm.

- Saturate the chamber for 20-30 minutes at room temperature.

- Develop the plate to a distance of 70-80 mm from the point of application [14].

- Remove the plate and dry thoroughly in a fume hood.

Documentation:

- Capture the chromatogram under UV light at 254 nm and 366 nm, and under white light after derivatization, if applicable. This creates the initial chemical fingerprint.

Bioautography Assay:

- Direct Bioautography: Prepare a suspension of the test microorganism (e.g., S. aureus) in a suitable broth (MHB) and adjust to a turbidity of 10^8 CFU/mL (0.5 McFarland standard). Spray the inoculated medium evenly over the dried HPTLC plate. Incubate the plate in a humid chamber at 37°C for 18-24 hours [12].

- Visualization: Spray the plate with an INT solution (0.2 mg/mL). Living metabolically active bacteria reduce the yellow INT dye to pink-purple formazan. Clear, colorless zones against a colored background indicate inhibition of bacterial growth, corresponding to the location of antimicrobial compounds [12].

Protocol 2: HPTLC-MS for Compound Identification

Following bioautography, this protocol enables the direct identification of active compounds from the HPTLC plate.

Workflow Overview:

Materials and Reagents:

- HPTLC Plate: From Protocol 1, with active zones located.

- HPTLC-MS Interface: Commercial interface (e.g., Camag TLC-MS Interface).

- Extraction Solvent: A volatile solvent like methanol or methanol-water mixture, optimized for the target compound.

- Mass Spectrometer: LC-MS or HRMS system with electrospray ionization (ESI) source [16].

Procedure:

- Zone Selection: Precisely mark the active zones (inhibition zones) identified in the bioautography assay.

- Zone Extraction: Using the TLC-MS interface, the selected zone is sealed, and the analyte is eluted directly from the plate into the mass spectrometer using a steady flow of solvent (e.g., 0.2 mL/min methanol) [16].

- MS Analysis: The eluted compounds are ionized (typically via ESI) and analyzed by the mass spectrometer. This provides molecular mass and fragmentation data for structural elucidation [11] [16].

- Data Interpretation: Compare the mass spectra obtained with compound databases or standards to propose the identity of the antimicrobial agent.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of HPTLC-based antimicrobial screening relies on specific reagents and materials. The following table lists key solutions and their critical functions.

Table 2: Key research reagent solutions for HPTLC antimicrobial screening

| Reagent/Material | Function/Explanation | Example Use Case |

|---|---|---|

| Silica Gel 60 F254 Plates | Standard stationary phase for normal-phase separation. F254 indicates a fluorescent indicator for UV visualization. | Core matrix for separating components of herbal extracts [13] [14]. |

| Iodonitrotetrazolium Chloride (INT) | Vital dye used in bioautography. Metabolically active microbes reduce yellow INT to pink formazan. | Visualizing zones of inhibition; clear zones indicate antimicrobial activity [12]. |

| CAMAG TLC-MS Interface | Specialized device that enables direct elution of compound bands from the TLC plate into a mass spectrometer. | Directly coupling separation to structural identification of active compounds [11]. |

| Metal-Organic Frameworks (MOFs) | Advanced functional nanomaterials used to modify HPTLC plates to enhance selectivity and pre-concentration of target analytes. | Improving sensitivity for detecting trace-level contaminants or active compounds in complex matrices [11]. |

| HPTLC Derivatization Reagents | (e.g., Anisaldehyde-sulfuric acid, NP/PEG). Chemicals sprayed post-development to reveal specific compound classes via color reactions. | Visualizing non-UV active antimicrobial compounds like certain terpenes or phenolics [17]. |

HPTLC stands out as a highly effective platform for antimicrobial screening, offering a unique combination of rapid parallel analysis, minimal solvent consumption, and direct linkage to biological activity through bioautography. Its compatibility with advanced detection techniques like MS and SERS transforms it from a simple separation tool into a comprehensive analytical platform. For researchers standardizing antimicrobial compounds from complex sources, HPTLC fingerprinting provides an unparalleled blend of efficiency, cost-effectiveness, and functional insight, accelerating the path from crude extract to identified bioactive lead.

The World Health Organization (WHO) provides a comprehensive framework for ensuring the safety, efficacy, and quality of herbal products throughout their lifecycle, from cultivation to consumption [18]. These guidelines are particularly crucial given that approximately 80% of the global population relies on traditional medicine, including herbal remedies, for primary healthcare [19] [20]. The regulatory landscape incorporates pharmacopeial standards and Good Manufacturing Practices (GMP) to address the complex challenges of herbal medicine quality control, especially relevant for research on bioactive antimicrobial compounds [20].

For researchers focusing on HPTLC fingerprinting of antimicrobial compounds, understanding this regulatory framework is essential. The chemical complexity of plants—containing alkaloids, flavonoids, terpenoids, phenolics, and polysaccharides—necessitates robust standardization methodologies [18]. These bioactive compounds exhibit diverse pharmacological activities, including antimicrobial effects, which must be consistently standardized across batches to ensure reliable therapeutic outcomes [2] [18].

WHO Guidelines for Herbal Medicine Quality Control

Fundamental Quality Control Parameters

WHO emphasizes that quality control encompasses all procedures undertaken to ensure the identity and purity of a health product [21]. For herbal medicines, this begins with proper identification of botanicals through macroscopic, microscopic, and molecular methods to prevent misidentification and adulteration [19]. The raw materials must meet minimum quality criteria regarding moisture, foreign matter, and active constituents before processing [19].

The WHO's comprehensive approach extends through the entire manufacturing process, requiring validated extraction processes and analytical method verification through techniques like chromatographic fingerprinting [19]. For antimicrobial research, this ensures that the bioactive compounds under investigation are consistently present and measurable across different batches. Furthermore, WHO mandates stability testing to determine shelf life and appropriate storage conditions, crucial for maintaining the potency of antimicrobial compounds [19].

Good Manufacturing Practice Requirements

WHO's GMP guidelines for herbal medicines require that manufacturing processes be validated, equipment calibrated, and operations conducted by qualified personnel [19] [20]. These practices are fundamental for ensuring that research on antimicrobial compounds translates reliably from laboratory settings to commercial products. The guidelines emphasize quality control throughout production, including in-process testing and final product assessment [19].

Documentation practices including Batch Manufacturing Records are critical components that enable traceability and quality monitoring [19]. For researchers, adhering to these standards ensures that experimental results are reproducible and clinically relevant. The WHO also highlights the importance of quality records and audit trails for effective monitoring and regulatory oversight [19].

Pharmacopeial Standards and Global Harmonization

Comparative Analysis of Major Pharmacopeias

Table 1: Key Pharmacopeial Standards for Herbal Medicines

| Pharmacopeia | Regional Focus | Standardization Approach | Key Features |

|---|---|---|---|

| U.S. Pharmacopeia (USP) | United States, recognized in >140 countries [22] | Identity, strength, quality, purity [22] | Botanical dietary supplements compendium [22] |

| European Pharmacopoeia | European Union [20] | Quality control of traditional Chinese medicine [20] | Harmonized standards across member states [20] |

| National Pharmacopeias | China, Japan, South Korea, Vietnam [20] | Based on traditional practices [20] | Reflect unique cultural and historical contexts [20] |

| Herbal Medicines Compendium (HMC) | Global [22] | Quality standards for traditional herbal medicines [22] | Publicly available standards [22] |

A global comparative analysis reveals significant variations in how different regions define and regulate herbal medicines [20]. These differences are influenced by national legal frameworks, regulatory requirements, and unique cultural influences [20]. For researchers conducting multi-center studies or developing products for international markets, understanding these distinctions is essential for protocol development and regulatory compliance.

The United States Pharmacopeia (USP), founded in 1820, provides processes and guidance to ensure medicines meet well-defined standards for safety and efficacy [22]. USP standards are legally recognized by more than 40 countries and used in over 140 countries [22]. The USP maintains several compendia specifically for botanicals, including the Dietary Supplements Compendium and the Herbal Medicines Compendium [22].

Harmonization Efforts

Despite regional variations, significant efforts toward international harmonization are underway. Organizations like the Forum on the Harmonization of Herbal Medicines (FHH) work to align standards across regions [20]. The WHO plays a crucial role in this harmonization through the development of global guidelines and technical support to member states [19] [18].

For researchers focusing on antimicrobial compounds from herbal medicines, this harmonization is particularly important for establishing globally accepted testing protocols and quality parameters. The WHO utilizes ISO standards for ensuring quality and test methods, along with Codex Alimentarius guidelines for herbal food supplements [19].

HPTLC Fingerprinting for Standardization of Bioactive Antimicrobial Compounds

Regulatory Basis for HPTLC in Quality Control

High-Performance Thin-Layer Chromatography plays a crucial role in establishing the chemical fingerprint of natural products during analysis [23]. Regulatory authorities worldwide recognize chromatographic fingerprinting as a valid approach for quality evaluation of herbal medicines [24]. The WHO specifically mentions TLC among the chemical experiments used to determine identity and screen for particular pharmaceutical substances [21].

The HPTLC Association maintains a collection of more than 300 methods for the identification of herbal drugs and herbal drug preparations, many of which have been adopted in monographs published by the European and United States Pharmacopeias [25]. These methods follow the Association's Standard Operating Procedure, ensuring reproducibility of results [25]. For antimicrobial research, this standardized approach allows for consistent profiling of bioactive compounds across different laboratories and study sites.

Advanced HPTLC Methodologies for Antimicrobial Compounds

Recent research demonstrates the application of HPTLC for profiling antimicrobial compounds in complex matrices. For example, a 2024 study on Nymphaea nouchali seeds used HPTLC to identify and quantify phenolic compounds, including catechin (3.06%), gallic acid (0.27%), and quercetin (0.04%), correlating these compounds with antimicrobial activity [2]. The method employed a Camag TLC system with chloroform:ethyl acetate:formic acid:methanol (2.5:2:0.4:0.2, v/v/v/v) as the mobile phase and densitometric scanning at 412 nm [2].

A novel strategy for quality evaluation of complex herbal preparations based on multi-color scale and efficacy-oriented HPTLC characteristic fingerprint combined with chemometric methods has been developed for comprehensive quality control [24]. This approach establishes highly specific characteristic fingerprints for each herbal medicine in a preparation, eliminating interference from other herbs and ensuring accuracy [24]. For antimicrobial research, this enables targeted analysis of specific bioactive compounds within complex mixtures.

Validated HPTLC Methods for Regulatory Compliance

Table 2: HPTLC Validation Parameters as per ICH Guidelines

| Parameter | Requirements | Application Example |

|---|---|---|

| Linearity | Specific range with correlation coefficient [13] | 0.03–3.00 µg/band for meloxicam, 0.50–9.00 µg/band for Florfenicol [13] |

| Detection | Densitometric at specific wavelengths [13] | 230 nm for Florfenicol and Meloxicam [13] |

| Mobile Phase | Optimized solvent system [13] | Glacial acetic acid:methanol:triethylamine:ethyl acetate (0.05:1.00:0.10:9.00) [13] |

| System Suitability | Must be met on individual HPTLC plate [25] | Appropriate fingerprint for identity standard [25] |

Regulatory-compliant HPTLC methods require validation according to ICH guidelines [13]. A 2025 study developed an FDA-validated ecofriendly HPTLC method for quantification of antimicrobial compounds, demonstrating linearity within specified ranges and using densitometric detection at 230 nm [13]. The method employed Esomeprazole as an internal standard to compensate for potential wavelength fluctuations [13].

The environmental impact of analytical methods is increasingly considered in regulatory frameworks. The greenness of the HPTLC method was evaluated using five greenness assessment tools, including greenness, whiteness, and blueness metrics, confirming its eco-friendly nature [13]. This aligns with broader regulatory trends toward sustainable analytical practices.

Experimental Protocols for HPTLC Fingerprinting of Antimicrobial Compounds

Standardized HPTLC Protocol for Reproducible Fingerprinting

The standardized procedure for HPTLC fingerprinting of antimicrobial compounds involves multiple critical steps to ensure regulatory compliance and reproducibility [23]. The process begins with sample preparation using authenticated plant material extracted with appropriate solvents (e.g., 70% ethanol for phenolic antimicrobial compounds) [2]. The extraction method should be validated for optimal recovery of target antimicrobial compounds.

Plate application utilizes pre-coated HPTLC plates (silica gel 60 F254) with automated applicators (e.g., Camag Linomat) for precise sample band application [13] [24]. The application volume should be optimized to ensure detection within the linear range of the target antimicrobial compounds. Chromatographic development occurs in twin-trough chambers pre-saturated with the mobile phase for 15-20 minutes [13]. The mobile phase must be optimized for specific separation of antimicrobial compounds; for phenolic antimicrobial compounds, chloroform:ethyl acetate:formic acid:methanol (2.5:2:0.4:0.2, v/v/v/v) has demonstrated efficacy [2].

Detection and Documentation Protocol

Detection employs multiple modes including UV at 254 nm and 366 nm, visible light, and specific derivatization reagents tailored to antimicrobial compound classes [24] [2]. For densitometric quantification, the wavelength must be optimized for target compounds (e.g., 230 nm for certain antimicrobial pharmaceuticals) [13]. Documentation includes capturing images under different illumination conditions and generating densitometric scans for quantitative analysis [24].

The data analysis phase involves calculating Rf values, comparing with reference standards, and applying chemometric methods for pattern recognition [24]. For antimicrobial compounds, this may include correlating fingerprint patterns with antimicrobial activity through multivariate analysis.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents for HPTLC of Antimicrobial Compounds

| Item | Function | Specification Example |

|---|---|---|

| HPTLC Plates | Stationary phase for separation | Silica gel 60 F254, 20×10 cm or 20×20 cm, 0.25 mm thickness [24] |

| Reference Standards | Compound identification and quantification | Certified reference materials for target antimicrobial compounds [24] |

| Mobile Phase Components | Chromatographic separation | HPLC-grade solvents; optimized for antimicrobial compounds [13] |

| Derivatization Reagents | Visualizing specific compound classes | Anisaldehyde sulfuric acid, NP/PEG for phenolics [24] |

| Internal Standards | Quantification accuracy | Esomeprazole for wavelength fluctuation compensation [13] |

| Extraction Solvents | Compound extraction from plant material | Ethanol, methanol, water in varying proportions [2] |

The selection of appropriate research reagents is critical for generating regulatory-compliant HPTLC data for antimicrobial compounds. HPTLC plates pre-coated with silica gel 60 F254 are the most widely used stationary phase, with 0.25 mm thickness providing optimal separation [24]. The plate size should be selected based on the number of samples to be analyzed, with 20×10 cm suitable for smaller batches and 20×20 cm for comprehensive studies.

Reference standards must be of pharmacopeial quality when available, with documented purity and sourcing [24]. For antimicrobial compounds not available as certified standards, purified isolates characterized by orthogonal methods may be used. Mobile phase components require HPLC-grade purity to minimize interference, with specific combinations optimized for different classes of antimicrobial compounds [13] [2].

The regulatory framework for herbal medicine quality control established by WHO and pharmacopeial standards provides a robust foundation for research on antimicrobial compounds using HPTLC fingerprinting. The integration of validated HPTLC methodologies within this regulatory context ensures that research outcomes are scientifically valid, reproducible, and translatable to product development.

For researchers focusing on bioactive antimicrobial compounds, adherence to these standards is essential for generating clinically relevant data. The continuing harmonization of global standards and the development of eco-friendly analytical methods represent significant advances in the field. By employing the protocols and methodologies outlined in this document, researchers can contribute to the development of safe, efficacious, and quality-controlled herbal medicines with validated antimicrobial activity.

Sample Preparation Techniques for Optimal Antimicrobial Compound Extraction

The pursuit of novel antimicrobial agents is a critical scientific endeavor in an era of rising antimicrobial resistance. The initial and most crucial step in this process is the efficient extraction of bioactive compounds from biological sources, which directly influences the success of subsequent isolation, identification, and standardization procedures. This document provides detailed application notes and protocols for sample preparation, framed within a research paradigm that utilizes High-Performance Thin-Layer Chromatography (HPTLC) fingerprinting for the standardization of bioactive antimicrobial compounds. Proper sample preparation is the foundation upon which reliable, reproducible, and analytically valid HPTLC results are built, ensuring that the resulting chemical and bioactivity profiles are accurate representations of the source material.

Core Extraction Principles and Method Selection

The primary goal of sample preparation is to efficiently isolate target antimicrobial compounds from a complex biological matrix while preserving their chemical integrity and bioactivity. The selection of an extraction method and solvent is guided by the chemical nature of the target compounds and the properties of the source material.

Solvent Selection Strategy

The choice of solvent is paramount and depends on the polarity of the anticipated bioactive compounds [26]. The following table summarizes common solvents and their applications.

Table 1: Common Solvents for Antimicrobial Compound Extraction

| Solvent | Polarity | Target Compound Classes | Considerations |

|---|---|---|---|

| n-Hexane | Non-polar | Lipophilic compounds, Chlorophyll removal | Often used for initial defatting or cleaning steps [26]. |

| Dichloromethane (DCM) | Moderate to low | Medium and low-polarity compounds | Effective for extracting a broad spectrum of antimicrobials; used in honey analysis [27]. |

| Ethyl Acetate | Intermediate | Flavonoids, Phenolic acids | Good balance of polarity and volatility; suitable for various secondary metabolites [28]. |

| Methanol/Ethanol | Polar | Flavonoids, Alkaloids, Polar phenolic acids | High extraction efficiency for a wide range of bioactive compounds; ethanol is safer [26] [29]. |

| Water | High | Polysaccharides, Polar glycosides, Proteins | Used in maceration or as a mixture with alcohol (e.g., methanol:water 8:2) [29]. |

Comparison of Extraction Techniques

Various techniques can be employed, each with distinct advantages and operational parameters. The choice often involves a trade-off between time, efficiency, and thermal sensitivity.

Table 2: Comparison of Common Extraction Techniques

| Extraction Method | Common Solvents | Temperature | Time Required | Key Advantages |

|---|---|---|---|---|

| Maceration | Methanol, Ethanol, Water | Room Temperature | 3–4 days | Simple, no specialized equipment needed [26]. |

| Soxhlet Extraction | Methanol, Ethanol, Hexane | Dependent on solvent boiling point | 3–18 hours | Exhaustive extraction, high efficiency [26]. |

| Sonification | Methanol, Ethanol | Can be heated | ~1 hour | Rapid, good efficiency for small samples [26]. |

| Solid-Phase Extraction (SPE) | Variable (used for cleanup) | Room Temperature | Varies | Purification and concentration of extracts [30]. |

The following workflow diagram illustrates the decision-making process for selecting and executing a sample preparation protocol leading to HPTLC analysis:

Detailed Experimental Protocols

Protocol 1: Extraction of Antimicrobial Compounds from Plant Material

This protocol is adapted from methods used for plants like Croton gratissimus and South African Combretaceae species [29] [31].

Objective: To extract medium- to high-polarity antimicrobial compounds (e.g., flavonoids, phenolic acids) from dried plant leaves for HPTLC fingerprinting and bioautography.

Materials & Reagents:

- Plant Material: Dried, powdered leaves (e.g., 10 g).

- Extraction Solvent: Methanol:Water mixture (8:2, v/v) [29].

- Equipment: Ultrasonic bath, filtration setup (Whatman No. 1 filter paper), rotary evaporator, glass vials.

Procedure:

- Weighing: Precisely weigh 1.0 g of the dried, homogenized plant powder into a sealed glass vial.

- Solvent Addition: Add 10 mL of the methanol:water (8:2, v/v) extraction solvent.

- Sonication: Place the vial in an ultrasonic bath and sonicate for 30 minutes at room temperature.

- Filtration: After sonication, filter the extract using filter paper into a round-bottom flask.

- Re-extraction: To ensure exhaustive extraction, repeat steps 2-4 on the residual plant material.

- Combination and Concentration: Combine the filtrates and concentrate to dryness under reduced pressure using a rotary evaporator (water bath temperature not exceeding 40°C).

- Reconstitution: Reconstitute the dried extract in 1 mL of dichloromethane or methanol to achieve a concentrated stock solution for HPTLC analysis.

- Storage: Store the final extract at 4°C until analysis.

Protocol 2: Extraction of Antimicrobial Metabolites from Microbial Broth

This protocol is based on procedures for isolating compounds from Streptomyces species [28].

Objective: To extract antimicrobial metabolites from the culture broth of fermenting bacteria or fungi.

Materials & Reagents:

- Source: Fermentation broth (e.g., of Streptomyces sp.), cell-free supernatant obtained by centrifugation.

- Extraction Solvent: Diethyl ether (Et₂O) or Ethyl Acetate (EtOAc) [28].

- Equipment: Separatory funnel, anhydrous MgSO₄ or Na₂SO₄, rotary evaporator.

Procedure:

- Separation: Centrifuge the fermentation broth to remove microbial cells. Use the cell-free supernatant.

- Liquid-Liquid Extraction: Transfer the supernatant to a separatory funnel. Add an equal volume of diethyl ether. Shake gently with periodic venting. Allow the phases to separate completely.

- Collection: Collect the organic (upper) layer.

- Re-extraction: Repeat the liquid-liquid extraction process twice more with fresh solvent.

- Drying: Combine all the organic extracts in a clean flask and add anhydrous magnesium sulfate (MgSO₄) to remove residual water. Swirl and let stand for 15 minutes.

- Filtration: Filter the dried extract through filter paper into a round-bottom flask.

- Concentration: Evaporate the solvent to dryness under reduced pressure using a rotary evaporator.

- Reconstitution and Storage: Reconstitute the residue in a small volume of methanol or DCM for HPTLC analysis and store at 4°C.

Protocol 3: HPTLC Analysis and Bioautography for Antimicrobial Activity

This protocol integrates chemical profiling with bioactivity screening, a powerful hyphenated technique [27] [31].

Objective: To separate the components of a crude extract and localize those with antimicrobial activity directly on the HPTLC plate.

Materials & Reagents:

- HPTLC Plates: Silica gel 60 F₂ₓ₄ (e.g., 20 x 10 cm).

- Sample Applicator: Semi-automated device (e.g., Linomat 5, CAMAG).

- Mobile Phase: System must be optimized. Example: Toluene:Ethyl Acetate:Formic Acid (6:5:1, v/v/v) for honey phenolics [27] or Ethyl Acetate:Acetic Acid:Formic Acid:Water (100:11:11:27, v/v/v/v) for plant extracts [29].

- Derivatization Reagents: Natural Product reagent (NP) or DPPH* for antioxidant activity [27] [29].

- Microbiological Materials: Mueller-Hinton Agar, test organism (e.g., Staphylococcus aureus, Bacillus subtilis), incubation equipment.

Procedure: Part A: HPTLC Fingerprinting

- Application: Using a semi-automated applicator, apply the reconstituted extracts and standards as 8 mm bands, 8 mm from the lower edge of the HPTLC plate.

- Chromatogram Development: Develop the plate in a pre-saturated twin-trough chamber with the optimized mobile phase until the solvent front has migrated approximately 80 mm from the origin.

- Drying: Air-dry the developed plate completely in a fume hood to remove all residual solvent.

- Documentation: Capture the chromatographic image under UV light (254 nm and 366 nm) and white light before and after derivatization.

Part B: Bioautography (Agar Overlay Assay)

- Preparation of Bioassay Plate: Prepare a thin layer of nutrient agar (e.g., Mueller-Hinton) seeded with a standardized suspension of the test microorganism (e.g., Bacillus subtilis) in a separate Petri dish.

- Transfer: Carefully overlay the developed and dried HPTLC plate onto the surface of the seeded agar. Ensure full contact and avoid air bubbles. Let it stand for 15-30 minutes to allow the diffusion of compounds from the plate into the agar.

- Incubation: Remove the HPTLC plate and incub the bioassay agar plate under appropriate conditions (e.g., 37°C for 24 hours) for the microorganism.

- Visualization: After incubation, clear zones of inhibition in the bacterial lawn will correspond to the location of antimicrobial compounds on the original HPTLC plate. The Rf values of these active bands can be recorded.

- Hyphenation with MS: For identification, the silica from the active bands (located via a parallel, non-overlaid plate) can be scraped off, eluted with a strong solvent, and subjected to mass spectrometric (MS) analysis [31].

The Scientist's Toolkit: Essential Research Reagents

The following table details key reagents and materials critical for the success of the extraction and HPTLC bioautography protocols described herein.

Table 3: Key Research Reagent Solutions for Extraction and HPTLC-Bioautography

| Reagent/Material | Function/Application | Notes |

|---|---|---|

| Methanol:Water (8:2, v/v) | A versatile solvent for extracting a broad range of medium- to high-polarity bioactive compounds from plant material [29]. | Adjust the ratio based on target compound polarity. |

| Diethyl Ether (Et₂O) | Used for liquid-liquid extraction of antimicrobial metabolites from aqueous fermentation broth [28]. | Highly volatile and flammable; requires careful handling in a fume hood. |

| Dichloromethane (DCM) | A medium-polarity solvent for re-extracting dried honey or for reconstituting dried extracts prior to HPTLC [27]. | Common solvent for lipophilic fractions. |

| HPTLC Silica Gel 60 F₂ₓ₄ Plates | The stationary phase for the high-resolution separation of complex extract mixtures [27] [30]. | Fluorescent indicator allows visualization under UV light. |

| DPPH* Derivatization Reagent | A spraying reagent used to visualize antioxidant compounds directly on the HPTLC plate as yellow bands on a purple background [27]. | Prepared as 0.04% (w/v) solution in 50% methanol/ethanol. |

| Vanillin / Anisaldehyde Reagents | General-purpose derivatization reagents that produce colored bands with various compound classes (terpenes, phenolics) upon heating [27] [30]. | Essential for creating comprehensive visual fingerprints. |

| Toluene:Ethyl Acetate:Formic Acid | A commonly used mobile phase system for the separation of phenolic compounds and flavonoids in natural product extracts [27]. | Ratios must be optimized for specific sample types. |

| Nutrient Agar & Test Strains | Required for bioautography to visualize antimicrobial activity. Common test strains include B. subtilis, S. aureus, and E. coli [28] [31]. | Strains are selected based on the research focus (e.g., MRSA for drug-resistant bacteria). |

Advanced HPTLC Method Development for Antimicrobial Profiling

Systematic Mobile Phase Optimization for Bioactive Compound Separation

High-performance thin-layer chromatography (HPTLC) is a sophisticated, robust, and cost-efficient analytical technique widely employed in pharmaceutical and natural product research for the separation, identification, and quantification of bioactive compounds [1]. Within the broader context of HPTLC fingerprinting for standardization of bioactive antimicrobial compounds, the critical factor governing the success of any HPTLC analysis is the selection and optimization of the mobile phase [32]. An optimally designed mobile phase ensures sufficient resolution of complex mixtures, enabling accurate bioautography and subsequent chemometric analysis for the detection of antimicrobial constituents [33] [34]. This protocol details a systematic strategy for mobile phase optimization to achieve reproducible separation of bioactive antimicrobial compounds from complex matrices, such as plant and marine organism extracts.

The Scientist's Toolkit: Essential Materials and Reagents

Table 1: Key Research Reagent Solutions for HPTLC Method Development

| Reagent/Material | Function/Application | Exemplary Use in Antimicrobial Research |

|---|---|---|

| HPTLC Silica gel 60 F₂₅₄ Plates | Stationary phase for chromatographic separation; F₂₅₄ indicates fluorescent indicator. | Standard support for separating complex extracts; used in analysis of Nymphaea nouchali seed antimicrobials [33]. |

| Solvents (e.g., Toluene, Ethyl Acetate, Chloroform, Methanol) | Components of the mobile phase; varying polarities to achieve desired separation. | Toluene:Ethyl Acetate:Acetic acid (60:37.5:2.5, V/V/V) effectively separated antioxidants and antimicrobials in marine sponge extracts [34]. |

| Derivatization Reagents (e.g., Sulfuric Vanillin, p-Anisaldehyde) | Chemical spraying agents to visualize non-UV active compounds by producing colored zones. | Used for post-chromatographic derivatization to detect various secondary metabolites after separation [32]. |

| Bioautography Reagents (e.g., DPPH, Microbial Suspensions) | Effect-directed analysis (EDA) reagents to locate bioactive zones directly on the plate. | DPPH for antioxidant activity; agar overlay with pathogenic bacteria (e.g., S. aureus, P. aeruginosa) for antimicrobial activity [33] [34]. |

| Standard Reference Compounds | Authentic compounds for co-chromatography to confirm identity and for calibration in quantification. | Essential for method validation and for identifying bioactive zones in complex mixtures via Rf value and spectrum comparison [32]. |

Systematic Mobile Phase Optimization Strategy

Mobile phase optimization is an iterative process that moves from general screening to fine-tuning, with the goal of achieving a robust system capable of resolving the compounds of interest from each other and from matrix interferences.

Initial Screening and Scouting

Begin by testing standard solvent systems of varying polarity and selectivity. A useful approach is to use PRISMA, a three-step optimization model involving (1) selection of solvents from different selectivity groups, (2) optimization of the solvent ratio, and (3) fine-tuning with modifiers [35].

- Solvent Selectivity Groups: Choose solvents from different selectivity groups (e.g., chloroform from Group I, ether from Group V, and acetic acid from Group I) to maximize the chance of achieving different selectivity patterns.

- Initial Binary and Ternary Mixtures: Start with simple mixtures (e.g., Hexane-Ethyl Acetate, Chloroform-Methanol, Toluene-Ethyl Acetate) and observe the migration of analytes and matrix components.

- Example from Literature: For the simultaneous determination of ivabradine and metoprolol, an optimized mobile phase of chloroform: methanol: formic acid: ammonia (8.5:1.5:0.2:0.1, v/v) provided excellent resolution [35]. This illustrates the use of a base solvent (chloroform), a polar modifier (methanol), and acidic and basic modifiers to control ionization and peak shape.

Fine-Tuning for Complex Bioactive Mixtures

The initial screening provides a starting point, but fine-tuning is often necessary for complex natural extracts containing antimicrobials.

- pH Modifiers (Acids/Bases): The addition of small amounts of formic acid, acetic acid, or ammonia can suppress the ionization of acidic or basic compounds, reducing tailing and improving spot shape. The analysis of phenolic compounds in Nymphaea nouchali seeds utilized acidic mobile phases for optimal separation [33].

- Solvent Strength and Selectivity Adjustment: Systematically adjust the volume ratios of the selected solvents. Even a 1-5% change can significantly impact resolution (Rf). The goal is to achieve Rf values for key analytes ideally between 0.2 and 0.8, with a difference of at least 0.05 between critical pairs.

- Resolution of Bioactive Zones: The ultimate test is the ability to resolve zones that show activity in bioautography. For instance, the separation of antibacterial and antioxidant compounds from marine sponges was achieved with Toluene: Ethyl acetate: Acetic acid (60:37.5:2.5, V/V/V), where acetic acid was critical for resolving the target bioactives [34].

Optimization and Validation Workflow

The following diagram illustrates the logical workflow for the systematic optimization of the HPTLC mobile phase.

Experimental Protocol: A Practical Guide

Materials and Instrumentation

- HPTLC Plates: HPTLC silica gel 60 F₂₅₄ (e.g., 10 cm x 10 cm or 20 cm x 10 cm).

- Application Device: Automated sample applicator (e.g., CAMAG Linomat 5).

- Development Chamber: Twin-trough glass chamber for saturated development.

- Densitometer: TLC Scanner (e.g., CAMAG TLC Scanner 3) controlled by winCATS or similar software.

- Documentation: TLC Visualizer or digital camera under UV light (254 nm, 366 nm) and white light after derivatization.

Step-by-Step Optimization Procedure

Sample Preparation:

- Dissolve the crude extract or standard compounds in a suitable solvent (e.g., methanol) at a typical concentration of 1-10 mg/mL.

- Centrifuge or filter (0.45 µm) to remove particulate matter.

Sample Application:

- Apply the sample as bands (e.g., 4-6 mm wide) onto the HPTLC plate using an automated applicator. A typical application volume is 1-10 µL.

- Maintain a consistent distance from the bottom (e.g., 8 mm) and edge (e.g., 10 mm) of the plate.

Chromatogram Development:

- Condition the twin-trough chamber with the mobile phase for 20-30 minutes at room temperature to achieve saturation.

- Develop the plate to a distance of 70-80 mm from the application point.

- Dry the plate completely in a fume hood after development.

Derivatization and Detection:

- Examine the plate under UV light at 254 nm and 366 nm.

- Derivatize with appropriate reagents (e.g., DPPH for antioxidants, sulfuric vanillin for general compounds, etc.).

- For antimicrobial detection, use bioautography by overlaying the plate with agar inoculated with a test microorganism (e.g., S. aureus, E. coli) [33].

Densitometric Evaluation and Data Analysis:

- Scan the plate at the appropriate wavelength in absorbance or fluorescence mode.

- Record the retention factor (Rf) and peak areas for all relevant bands.

- Use chemometric tools or software to compare chromatographic profiles.

Table 2: Key Mobile Phase Formulations for Bioactive Compound Separation from Literature

| Analyte / Extract | Optimized Mobile Phase Composition (v/v/v) | Key Separation Outcome | Source |

|---|---|---|---|

| Ivabradine & Metoprolol | Chloroform : Methanol : Formic Acid : Ammonia (8.5 : 1.5 : 0.2 : 0.1) | Successful resolution of two cardiovascular drugs in a single run. | [35] |

| Marine Sponge Bioactives (e.g., Avarol) | Toluene : Ethyl Acetate : Acetic Acid (60 : 37.5 : 2.5) | Effective separation of single antimicrobial and antioxidant compounds for direct bioautography. | [34] |

| Phenolics in N. nouchali Seeds | Chloroform : Ethyl Acetate : Formic Acid : Methanol (2.5 : 2 : 0.4 : 0.2) | Quantification of catechin, gallic acid, and quercetin linked to antimicrobial activity. | [33] |

Integration with Chemometrics and Bioautography

The final optimized HPTLC method is not an endpoint but a starting point for advanced analysis within a standardization workflow.

- Chemometric Analysis: The densitometric data (peak areas and Rf values) from the optimized separation can be subjected to multivariate statistical analysis, such as the sparse Heterocovariance Approach (sHetCA), to correlate chemical profiles with biological activity across multiple fractions [32]. This helps pinpoint which resolved compounds are responsible for the observed antimicrobial effect.

- Hyphenation with Spectroscopic Techniques: Bioactive zones resolved with the optimized mobile phase can be scraped off, eluted, and directly characterized using techniques like FTIR, NMR, or HRMS for structural elucidation [34]. This creates a powerful pipeline from separation to identification.

The following workflow integrates mobile phase optimization into a comprehensive HPTLC-based strategy for discovering bioactive antimicrobial compounds.

Concluding Remarks

A systematic approach to mobile phase optimization is foundational to developing robust HPTLC methods for the standardization of bioactive antimicrobial compounds. By moving from initial solvent screening to fine-tuning with modifiers and validating separation efficiency through bioautography, researchers can establish reliable HPTLC fingerprints. These fingerprints, when integrated with chemometrics and modern spectroscopic techniques, form a comprehensive strategy for the discovery, authentication, and quality control of complex natural products, directly supporting the objectives of a thesis in this field. The protocols and data presentation formats detailed here provide a clear roadmap for researchers and drug development professionals.

In High-Performance Thin-Layer Chromatography (HPTLC), the stationary phase (sorbent) is a critical determinant for achieving high-resolution separations essential for standardizing bioactive antimicrobial compounds [1]. The selection of an appropriate sorbent directly influences the efficiency, reproducibility, and overall success of the analytical method, impacting parameters such as resolution, analysis time, and detection sensitivity [36] [37]. Modern HPTLC utilizes a diverse range of sophisticated stationary phases that extend far beyond conventional silica gel, each offering unique selectivity profiles for different classes of antimicrobial compounds [36] [38]. These sorbents are typically coated on glass or aluminum backing in layers approximately 0.25 mm thick, with particle sizes optimized to 5-7 µm for superior performance compared to traditional TLC [36] [37]. This article provides a comprehensive guide to stationary phase selection, supported by structured protocols for antimicrobial compound research.

Silica Gel-Based Sorbents

Classical Silica Gel HPTLC Plates represent the most widely used normal-phase stationary phase, comprising porous silica gel 60 with a particle size of 5-6 µm and often containing fluorescent indicators (F254 or F254s) for UV visualization [36]. The separation mechanism relies on adsorption chromatography, where analytes interact with surface silanol groups through hydrogen bonding and dipole-dipole interactions [36] [38]. These plates are particularly suitable for separating moderately polar to non-polar antimicrobial compounds, including many natural product extracts and pharmaceutical formulations [36] [1].

Premium Purity Silica Gel Plates are specially manufactured to prevent contamination from plasticizers, which is crucial when analyzing antimicrobial compounds where unknown additional zones could interfere with results [36]. These plates are packaged in plastic-coated aluminum foil and are recommended for pharmacopeia applications and sensitive analyses requiring the highest level of purity [36].

LiChrospher HPTLC Plates incorporate spherical silica particles with a narrow size distribution (7 µm), providing enhanced separation efficiency and reduced analysis times compared to conventional HPTLC plates [36]. The spherical geometry creates a more homogeneous layer with improved flow characteristics, leading to highly compact spots or zones that significantly improve detection sensitivity for trace antimicrobial compounds in complex matrices [36].

Chemically Modified Sorbents

Reversed-Phase Sorbents include RP-2, RP-8, and RP-18 modifications, where silica gel is derivatized with dimethyl- (RP-2), octyl- (RP-8), or octadecyl- (RP-18) silane groups [36]. These sorbents operate on a partition chromatography mechanism, where separation depends on the differential partitioning of analytes between the polar mobile phase and the hydrophobic stationary phase [36]. The RP-18W variant features a lower degree of surface modification, allowing operation with 100% aqueous mobile phases, which is particularly beneficial for polar antimicrobial compounds [36].

Polar Modified Sorbents include CN (cyano), DIOL, and NH2 (amino) functionalities, offering intermediate polarity and versatile applications [36]. CN-modified plates (cyanopropyl groups) can operate in both normal-phase and reversed-phase modes, enabling unique two-dimensional separations [36]. DIOL plates (vicinal diol alkyl ether) provide moderately polar characteristics with hydrogen-bonding capacity, while NH2-modified plates exhibit weakly basic ion-exchange properties with exceptional selectivity for charged molecules such as nucleotides and sulfonic acids [36].

Cellulose-Based Sorbents consist of microcrystalline cellulose arranged in a rod-shaped structure and are specifically designed for separating hydrophilic compounds through partition chromatography [36]. These plates are particularly valuable for analyzing antimicrobial compounds such as nucleic acids, phosphates, carbohydrates, and amino acids, and are notably beneficial for two-dimensional separations in metabolic studies [36].

Table 1: Comparative Characteristics of HPTLC Stationary Phases for Antimicrobial Compound Analysis

| Stationary Phase Type | Particle Size (µm) | Separation Mechanism | Optimal Application for Antimicrobial Compounds | Tolerance to Aqueous Solvents |

|---|---|---|---|---|

| Silica Gel 60 | 5-6 | Adsorption | Medium to non-polar antimicrobials; herbal extracts | Low |

| LiChrospher Silica | 7 (spherical) | Adsorption | High-throughput analysis of complex antimicrobial mixtures | Low |

| RP-2 | 5-6 | Partition | Polar to medium-polarity antimicrobials | Up to 80% water |

| RP-8 | 5-6 | Partition | Medium to non-polar antimicrobials | Up to 60% water |

| RP-18 | 5-6 | Partition | Non-polar antimicrobials; lipophilic compounds | Up to 60% water |

| RP-18W | 5-6 | Partition | Highly polar, water-soluble antimicrobials | 100% water |

| CN-Modified | 5-6 | Mixed-mode | Versatile for both polar and non-polar antimicrobials | Moderate |

| DIOL-Modified | 5-6 | Hydrogen bonding | Compounds with hydrogen-bonding functionality | Moderate |

| NH2-Modified | 5-6 | Ion-exchange | Charged antimicrobials; nucleotides, sulfonic acids | High |

| Cellulose | Microcrystalline | Partition | Hydrophilic antimicrobials; carbohydrates, amino acids | High |

Table 2: Performance Characteristics of Different HPTLC Sorbents

| Stationary Phase | Separation Efficiency | Development Time | Detection Sensitivity | Reproducibility | Humidity Dependence |

|---|---|---|---|---|---|

| Classical Silica | High | 7-20 minutes | 5-10x better than TLC | High | High |

| LiChrospher | Very High | 20% faster than HPTLC | Enhanced | Very High | High |

| Reversed-Phase | High | 10-25 minutes | High | High | Low |

| Polar Modified | Medium-High | 10-20 minutes | High | High | Low-Medium |

| Cellulose | Medium | 15-30 minutes | Medium | Medium | Low |

Selection Criteria for Antimicrobial Compound Analysis

Chemical Properties of Target Analytics

The chemical characteristics of antimicrobial compounds fundamentally guide stationary phase selection. Key considerations include polarity (hydrophilic compounds separate well on cellulose or NH2-modified phases, while lipophilic compounds are ideal for reversed-phase sorbents), ionization state (ionizable compounds benefit from NH2-modified phases with ion-exchange capabilities or reversed-phase with pH-controlled mobile phases), functional groups (hydrogen-bonding compounds interact well with DIOL phases, while aromatic systems separate effectively on silica gel), and molecular size (larger molecules require sorbents with appropriate pore sizes) [36] [34].

For complex antimicrobial extracts containing compounds with diverse polarities, such as marine sponge metabolites (including alkaloids and terpenoids), CN-modified plates offer unique advantages as they accommodate both normal-phase and reversed-phase mechanisms, enabling comprehensive profiling in a single analysis [36] [34].

Mobile Phase Compatibility

Stationary phase selection must consider mobile phase requirements. Normal-phase silica gel operates with organic solvents (hexane, ethyl acetate, chloroform, methanol mixtures), while reversed-phase sorbents require aqueous-organic mixtures [36] [37]. The RP-18W sorbent is particularly valuable for highly polar, water-soluble antimicrobials as it tolerates 100% aqueous mobile phases without destabilization [36].

Detection Requirements

Detection methodology significantly influences sorbent selection. For UV detection at 254 nm, sorbents with acid-stable fluorescent indicators (F254s) provide optimal sensitivity through fluorescence quenching [36]. For post-chromatographic derivatization with specific detection reagents (e.g., anisaldehyde for terpenoids), premium purity plates prevent interference from sorbent impurities [36]. Bioautography detection requires sorbents with minimal background bioactivity; silica gel and cellulose typically perform well in antimicrobial bioassays [34].

Sample Complexity